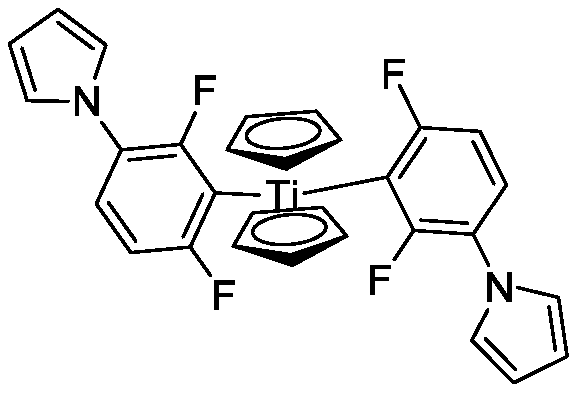

Synthesis method of photoinitiator FMT intermediate

A synthesis method and photoinitiator technology, applied in chemical recycling, organic chemistry, etc., can solve the problems of high price, insufficient yield, complicated production process, etc., and achieve the effects of cost saving, simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention relates to a synthesis method of a photoinitiator FMT intermediate. 2,4-difluorophenylpyrrole is an important intermediate for preparing the photoinitiator FMT, and a suitable preparation method is indispensable. The invention provides a route of cheap and easy-to-obtain raw materials, recyclable catalyst and solvent, simple and convenient operation, high yield, environmental protection and easy industrialization.

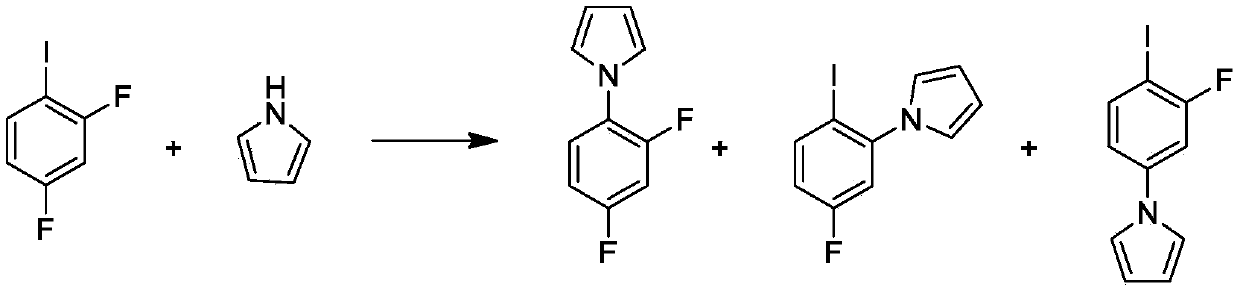

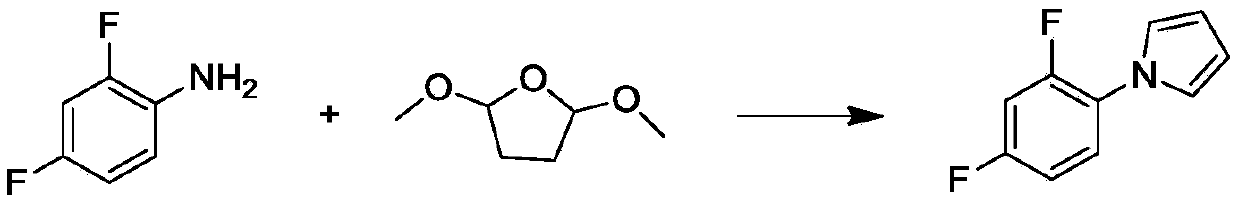

[0030] The synthesis route of this scheme is as follows:

[0031]

[0032] 2,4-Difluoroaniline and furan are in a polar solvent, under the catalysis of sulfonated polystyrene microspheres, the sealed heat preservation reaction is prepared 2,4-difluorophenylpyrrole, wherein 2,4 in the raw material - Both difluoroaniline and furan are conventional commercially available raw materials, and the preparation of sulfonated polystyrene microspheres can refer to the existing sulfonation method of polystyrene microspheres. For example, the following ...

Embodiment 1

[0040] Toluene (10L), 2,4-difluoroaniline (1.3kg) and furan (816g) were successively added to a stirred 20L reaction flask, catalyst sulfonated polystyrene microspheres (130g) were added, heated to 80°C, Seal and keep warm for 12 hours to complete the reaction, cool to room temperature, filter and recover the catalyst sulfonated polystyrene microspheres, directly concentrate under reduced pressure and steam out toluene and furan (for recycling), the crude product is beaten and washed with petroleum ether, filtered, and dried to obtain white Solid 2,4-difluorophenylpyrrole 1.65kg, yield 92.2%, HPLC: 99.2%.

[0041] LCMS(ESI): 180[M+H + ]

[0042] 1 H NMR (400MHz, CDCl 3 )δ7.36(td, J1=8.8, J2=5.8Hz, 1H), 7.01–6.91(m, 4H), 6.35(t, J=2.2Hz, 2H).

Embodiment 2

[0044] Add N,N-dimethylformamide (1L), 2,4-difluoroaniline (130g) and furan (206g) to a stirred 2L reaction flask in turn, add catalyst sulfonated polystyrene microspheres (13g ), heated to 60°C, sealed and kept warm for 15 hours, the reaction was complete, the catalyst sulfonated polystyrene microspheres were recovered by filtration, concentrated under reduced pressure and steamed out N,N-dimethylformamide and furan (recycled), crude oil was used Washed by beating with ether, filtered and air-dried to obtain 170 g of white solid 2,4-difluorophenylpyrrole with a yield of 95.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com