Purification method and crystal form of berberine or its salt

A purification method and technology for berberine, applied in the field of purification of berberine or its salt, can solve the problems of low efficiency, inability to meet standards, low success rate and the like, and achieve the effects of simple operation, mild reaction conditions and guaranteed safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

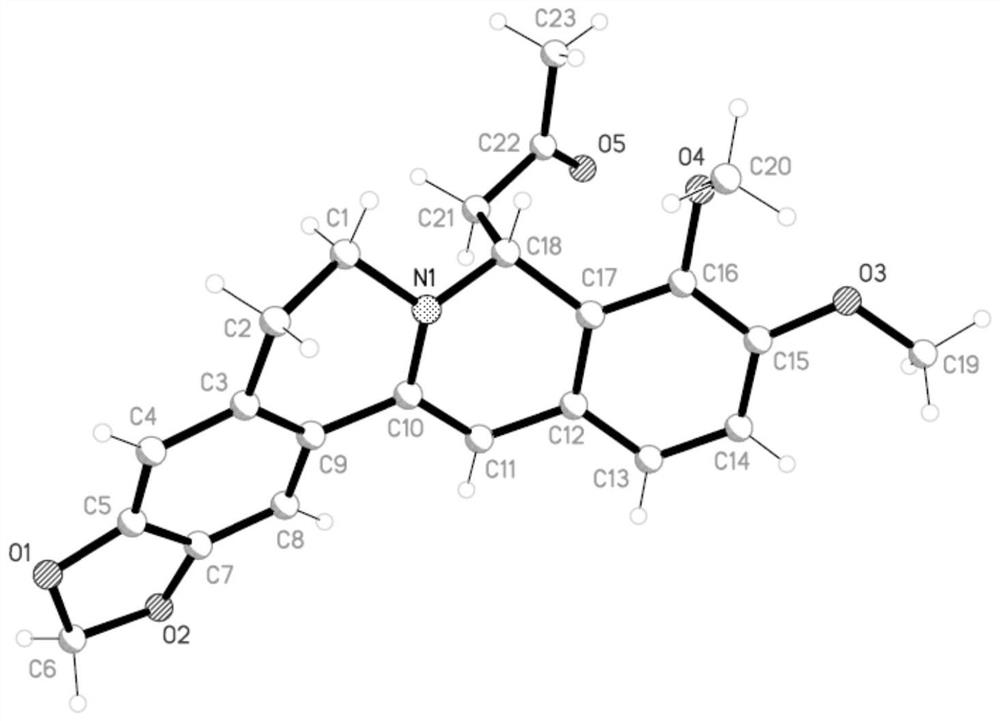

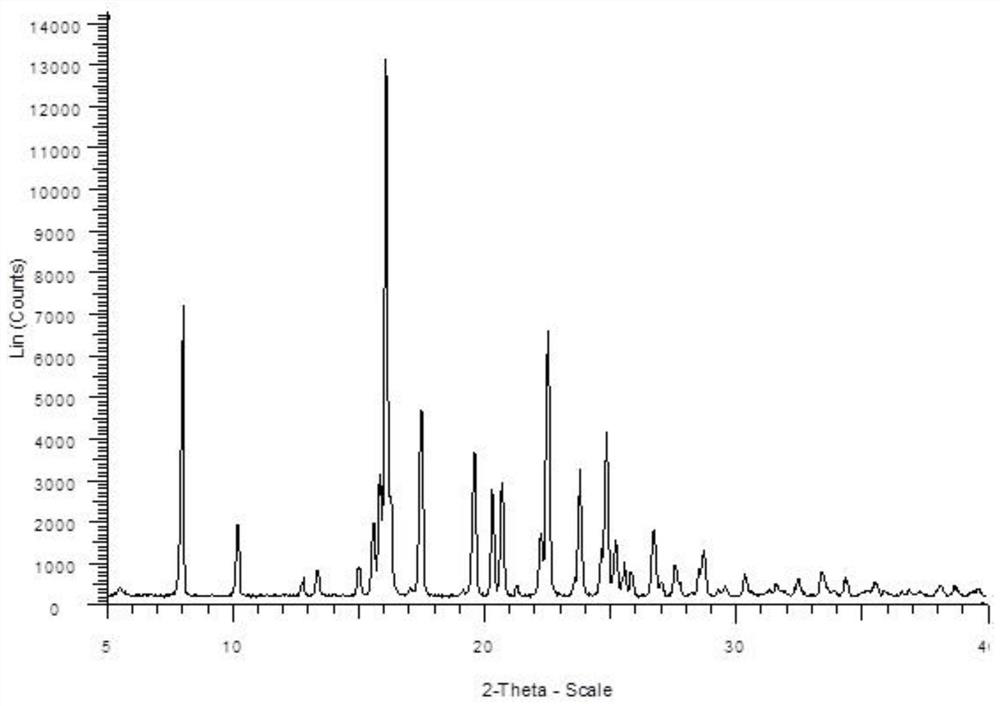

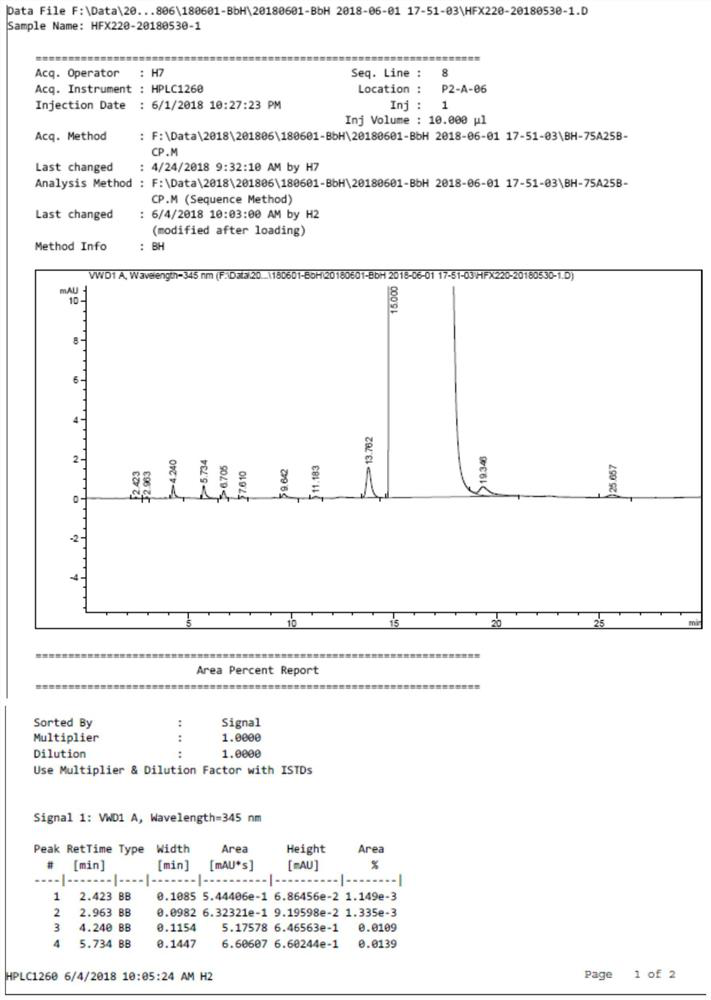

[0079] 38.3 g of berberine sulfate (0.10 mmol, 87% purity) were dissolved in 2.0 L of water to give a brown solution, and 0.10 L of 1N aqueous sodium hydroxide solution was added at room temperature. After stirring at room temperature, 0.01 liter (small amount) of acetone was added dropwise. After the light yellow crystals were precipitated, stirring was continued for 2 hours, and the light yellow berberine acetone adduct was obtained by filtration. The single crystal structural formula of the obtained acetone adduct is as follows figure 1 shown (single crystal analysis using a Bruker Apex diffractometer, purchased from Bruker AXS Inc TM (Madison, Wisconsin). Diffraction data were collected at 23°C using a Mo source). The XRD diffraction pattern of the obtained acetone adduct is shown in figure 2 (Performed using a Bruker D8 diffractometer, available from Bruker AXS Inc TM (Madison, Wisconsin), assayed by mounting the sample (approximately 10 mg) on a single crystal si...

Embodiment 2

[0090] 32 g of berberine hydrochloride (purity of 90%) and 1280 ml of methanol were added dropwise with 428 ml of 0.2N NaOH at about 20° C. to obtain a brown clear liquid. After the dropping was completed, the mixture was stirred for 10 min and filtered, and 172 ml of acetone was added dropwise to the filtrate. After dripping, the temperature was lowered to 10-15 °C, stirred for 2 h, filtered, and dried at room temperature to obtain berberine acetone complex. The XRD data were consistent with figure 2 Basically the same. Put the whole batch of wet products and 1600ml of water into a 2000ml bottle, and add 160ml of 1mol / L hydrochloric acid dropwise. After dripping, the temperature was raised to 80-100°C to obtain a yellow liquid and kept for 10min. After the heat preservation is completed, the temperature is lowered to below 30°C to obtain a yellow needle-like or yellow fibrous solid, which is filtered by suction, rinsed with water, and dried by suction, namely 27.2g of berb...

Embodiment 3

[0092] Utilize 86% berberine acetate to replace "38.3 grams of berberine sulfate" in Example 1, the molar weight is the same, carry out the same reaction, and finally the yield of berberine hydrochloride obtained is 85%, purity 99.85 %, and the single impurity content is lower than 0.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com