Polyimide, polyimide film and preparation method thereof

A polyimide film and polyimide technology, applied in the field of film materials, can solve the problems of backward commercialization of polyimide, high melting temperature, and high technical threshold, and achieve significant charge transfer, uniform arrangement, and increase in The effect of a large degree of coloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

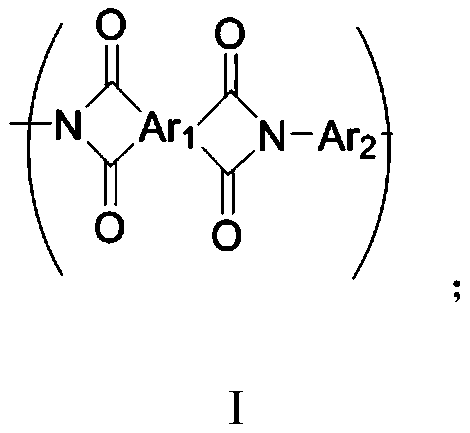

[0044] This embodiment provides a kind of polyimide and film thereof, and the chemical structural formula of polyimide is as follows (formula 1 in the summary of the invention):

[0045]

[0046] The preparation method of this polyimide film comprises the following steps:

[0047] (1) Under nitrogen protection, in the mixed solution of p-phenylenediamine (p-PDA, 10.81g, 0.10mol) and N-methylpyrrolidone (200mL) which is stirring, according to 1(4.66g):2( 9.32g): 3 (13.97g) monomer mass ratio Add 3,3',4,4'-biphenyltetracarboxylic dianhydride (s-BPDA, 27.95g, 0.095mol) three times for condensation reaction, wherein, The reaction temperature was 30° C., the stirring rate was 200 rpm, and the reaction time was 8 hours to obtain a polyamic acid solution.

[0048] (2) Take 20 mL of the polyamic acid solution obtained above and apply it evenly on a glass plate, place it on a hot plate at 100° C. for drying for 1 hour, and then peel it off from the glass plate to obtain a self-supp...

Embodiment 2

[0051] This embodiment provides a kind of polyimide and film thereof, and the chemical structural formula of polyimide is as follows (formula 1 in the summary of the invention):

[0052]

[0053] The preparation method of this polyimide film comprises the following steps:

[0054] (1) Under nitrogen protection, in a stirred mixed solution of p-phenylenediamine (p-PDA, 10.81g, 0.10mol) and N,N-dimethylacetamide (200mL), according to 1 (4.66g ):2(9.32g):3(13.97g) monomer mass ratio Add 3,3',4,4'-biphenyltetracarboxylic dianhydride (s-BPDA, 27.95g, 0.095mol) three times for condensation Reaction, wherein, the reaction temperature is 30°C, the stirring rate is 300rmp, and the reaction time is 8h to obtain a polyamic acid solution.

[0055] (2) Take 20 mL of the polyamic acid solution obtained above and apply it evenly on a glass plate, place it on a hot plate at 100° C. for drying for 1 hour, and then peel it off from the glass plate to obtain a self-supporting film.

[0056] (...

Embodiment 3

[0058] This embodiment provides a kind of polyimide and film thereof, and the chemical structural formula of polyimide is as follows (formula 1 in the summary of the invention):

[0059]

[0060] The preparation method of this polyimide film comprises the following steps:

[0061] (1) Under nitrogen protection, in the mixed solution of p-phenylenediamine (p-PDA, 10.81g, 0.10mol) and dimethylformamide (200mL) which is stirring, according to 1(4.66g):2( 9.32g): 3 (13.97g) monomer mass ratio Add 3,3',4,4'-biphenyltetracarboxylic dianhydride (s-BPDA, 27.95g, 0.095mol) three times for condensation reaction, wherein, The reaction temperature was 30° C., the stirring rate was 500 rpm, and the reaction time was 8 hours to obtain a polyamic acid solution.

[0062] (2) Take 20 mL of the polyamic acid solution obtained above and apply it evenly on a glass plate, place it on a hot plate at 100° C. for drying for 1 hour, and then peel it off from the glass plate to obtain a self-suppor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com