Light composite rubber and preparation method thereof

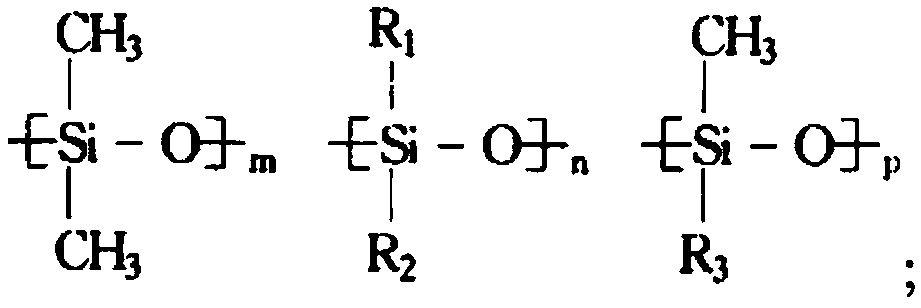

A lightweight, composite technology, applied in the rubber field, can solve the problems of decreased mechanical properties and flame retardant properties, pollute the environment, not environmental protection, etc., and achieve the effect of improving mechanical properties and thermal insulation properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] In this application, the silica airgel / hollow glass microsphere composite was first prepared, which is an important component of lightweight composite rubber, and its preparation method directly affects the performance of lightweight composite rubber. Specifically, the embodiment of the present invention discloses a preparation method of a silica airgel / hollow glass microsphere composite, comprising the following steps:

[0031] A) mixing methyltrimethoxysilane, ethyl orthosilicate, silane coupling agent, water, ethanol and an acidic catalyst to obtain a modified silica sol;

[0032] B) cross-linking the modified silica sol with a basic catalyst to obtain a modified silica gel;

[0033] C) mixing the modified silica gel with hollow glass microspheres to obtain a modified silica gel / hollow glass microsphere composite;

[0034] D) The modified silica gel / hollow glass microsphere composite is solvent replaced and then vacuum-dried to obtain a silica airgel / hollow glass mi...

Embodiment 1

[0073] Embodiment 1 provides a kind of preparation method of lightweight composite rubber containing aerogel, and the detailed preparation steps are as follows:

[0074] (1) Mix methyltrimethoxysilane, ethyl orthosilicate, water, and ethanol with a molar ratio of 1:3:10:30, add 1mol / L acetic acid drop by drop to adjust the pH to about 2, and control the reaction temperature After 15 minutes at 55°C, after the silicon source is fully hydrolyzed, a certain amount of γ-aminopropyltriethoxysilane is added to dehydrate and condense with the hydroxyl groups on the surface of the silica sol to obtain a modified silica sol;

[0075] (2) Add 0.5mol / L sodium hydroxide dropwise to the modified silica sol obtained in step (1), until the pH is adjusted to 7-8, and the cross-linking reaction obtains the modified silica gel;

[0076] (3) Add the modified silica gel and hollow glass microspheres VS5500 obtained in step (2) into a low-speed mixer respectively, and mix and stir at 30 rpm for 5 ...

Embodiment 2

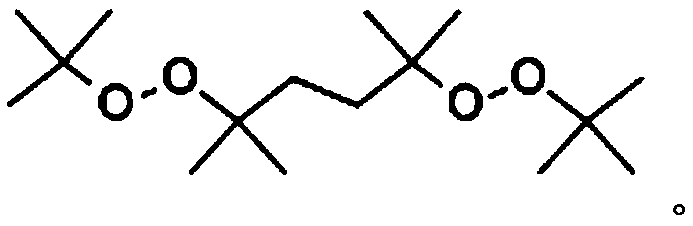

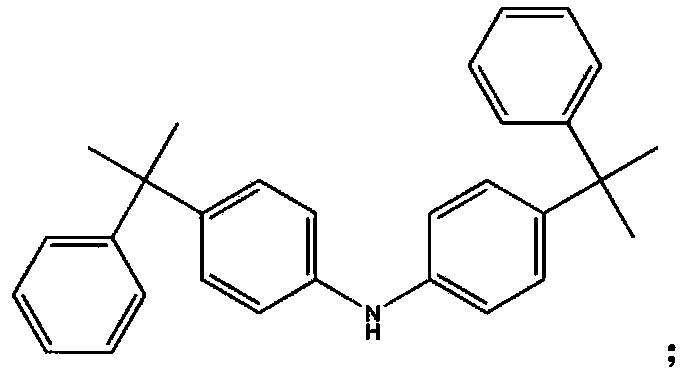

[0085] The difference between Example 2 and Example 1 is that the ratio of raw materials in parts by weight is: 67.5 parts of raw methyl vinyl silicone rubber, 5 parts of silica airgel / hollow glass microsphere composite, flame retardant MM -38 parts of F, 15 parts of hydroxy silicone oil, 1 part of 2,5-dimethyl-2,5-bis(tert-butyl peroxy), 4,4'-bis(α,α-dimethylbenzyl) 1 part of diphenylamine, 0.5 part of 2-mercaptobenzimidazole and 2 parts of zinc stearate, wherein, the silica airgel and hollow glass microspheres in the composite of silica airgel / hollow glass microspheres The weight ratio of VS5500 is 1:4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| True density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com