Water-based polyvinylidene fluoride coating slurry, battery diaphragm and preparation method of slurry

A polyvinylidene fluoride, coating technology, used in polyurea/polyurethane coatings, battery pack parts, coatings, etc., can solve the problem of poor comprehensive performance, low bonding performance, and inability to effectively bond negative pole pieces, etc. problem, to achieve the effect of high bond strength, high bond strength and good battery cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] In the water-based polyvinylidene fluoride coating slurry in this example, particles with a particle size of 2.5 μm prepared by polyvinylidene fluoride are dispersed in deionized water, and a water-soluble polyacrylic acid resin binder with a molecular weight of 200,000 is added. Prepare the water-based polyvinylidene fluoride coating slurry of this example with 90,000 polyacrylic resin adhesion promoter, carboxymethyl cellulose thickener, and propylene glycol wetting agent. Wherein, the viscosity of the binder is 70 mPa·s, the pH value is 7, the solid content is 40%, and the particle size is 350 nm; the particle size of the adhesion promoter is 180 nm. The specific preparation method of the water-based polyvinylidene fluoride coating slurry of this example is as follows:

[0044] 1) Use 0.12g of thickener to mix 11.88g of deionized water, use a mixer to stir at a speed of 120r / min for 1 hour, stir until a clear and transparent yellowish liquid, if the liquid has not re...

Embodiment 2

[0057] This example adopts the emulsion polyacrylic resin binder that molecular weight is 200,000, replaces the binder of embodiment 1; The viscosity of binder is 120mPa s, and pH value is 8, and solid content is 42%, and particle size is 500nm; All the other components, consumption and preparation method are the same as in Example 1.

[0058] The water-based polyvinylidene fluoride coating slurry of this example was obtained by filtering through the same filter screen as in Example 1.

[0059] Using the same base film and coating amount as in Example 1, a polyvinylidene fluoride-coated diaphragm with a coating thickness of 2 μm and a total thickness of 18 μm in this example was prepared.

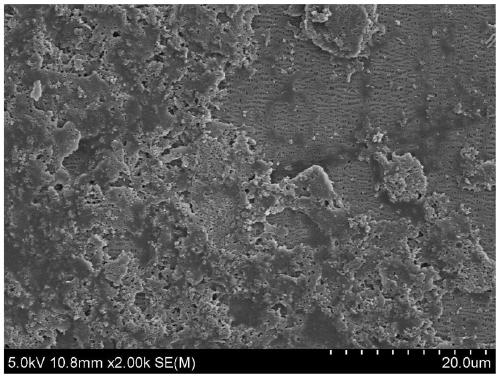

[0060] The coating of the polyvinylidene fluoride coated diaphragm prepared in this example is observed by scanning electron microscope, the results are as follows figure 2 shown. figure 2 The results show that the PVDF-coated separator of this example has a uniform coating, which is in...

Embodiment 3

[0064] This example adopts different adhesion promoters on the basis of Example 1, as follows:

[0065] Test 1: Polyurethane with a molecular weight of 100,000 was used to replace the polyacrylic resin in Example 1 as the adhesion promoter; the particle size of the adhesion promoter was 230 nm.

[0066] Experiment 2: Polyvinyl alcohol with a molecular weight of 60,000 was used to replace the polyacrylic resin in Example 1 as the adhesion promoter; the particle size of the adhesion promoter was 120 nm.

[0067] All the other are identical with embodiment 1.

[0068] Using the same filter screen as in Example 1 to filter, the slurry using the adhesion promoter of test 1 is marked as water-based polyvinylidene fluoride coating slurry 1, and the slurry using the adhesion promoter of test 2 is marked as water-based polyvinylidene fluoride coating Slurry 2.

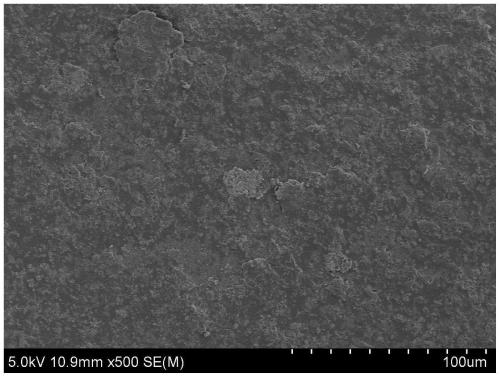

[0069] Using the same base film and coating amount as in Example 1, this example uses water-based polyvinylidene fluoride c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com