High-temperature-resistant powder coating and preparation method thereof

A technology of powder coating and high temperature resistance, applied in the direction of powder coating, fireproof coating, polyester coating, etc. Problems such as spraying effect, to improve spraying effect and spraying quality, improve pressure resistance, and save money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

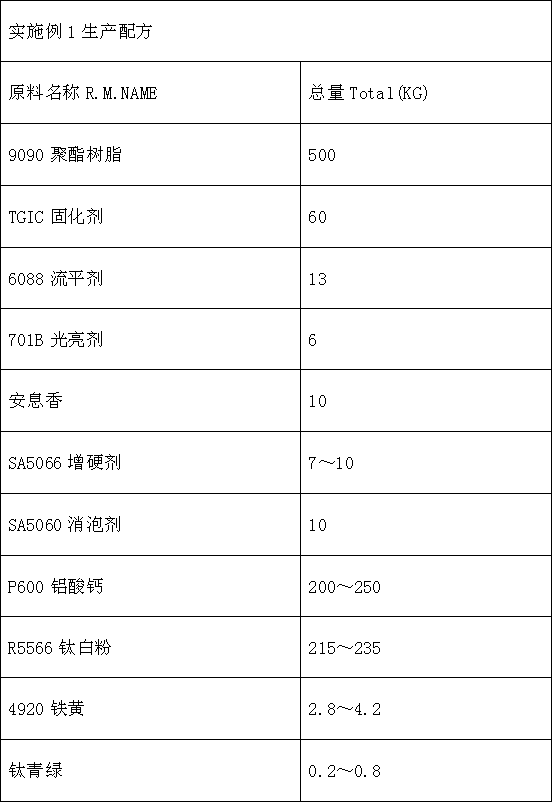

Embodiment 1

[0028] A high-temperature-resistant powder coating, in parts by weight, its raw material composition includes: 500 parts of 9090 polyester resin, 60 parts of TGIC curing agent, 13 parts of 6088 leveling agent, 6 parts of 701B brightener, 10 parts of benzoin, SA5066 7-10 parts of hardener, 200-240 parts of pigment agent, 10 parts of SA5060 defoamer, 200-250 parts of P600 calcium aluminate.

[0029] In terms of parts by weight, the pigment agent includes: 215-235 parts of R5566 titanium dioxide, 2.8-4.2 parts of 4920 iron yellow, and 0.2-0.8 parts of titanium cyan green.

[0030] A preparation method for high temperature resistant powder coatings, comprising the following steps in turn:

[0031] S1: raw material preparation; weigh 9090 polyester resin, TGIC curing agent, 6088 leveling agent, 701B brightener, benzoin, SA5066 hardening agent, pigment agent, SA5060 defoamer, and P600 calcium aluminate in parts by weight;

[0032] S2: pre-mixing; pre-mixing the prepared raw materia...

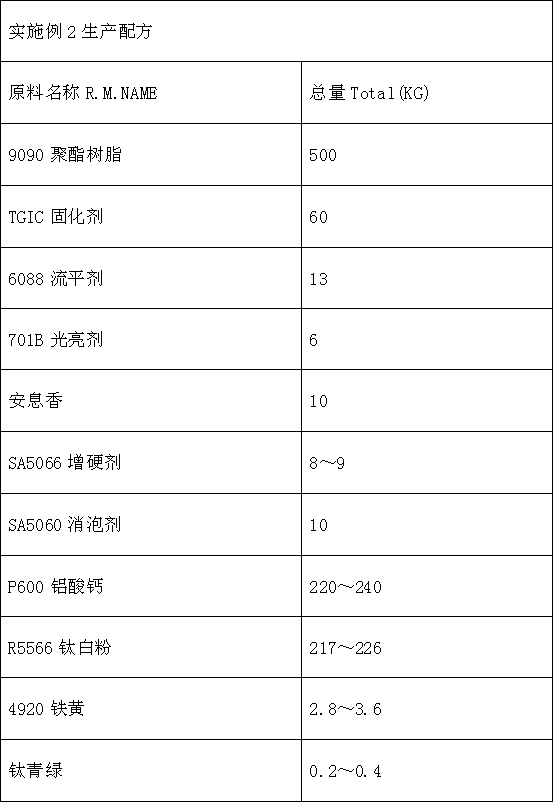

Embodiment 2

[0038] A high-temperature-resistant powder coating, in parts by weight, its raw material composition includes: 500 parts of 9090 polyester resin, 60 parts of TGIC curing agent, 13 parts of 6088 leveling agent, 6 parts of 701B brightener, 10 parts of benzoin, SA5066 8-9 parts of hardener, 220-230 parts of pigment agent, 10 parts of SA5060 defoamer, 220-240 parts of P600 calcium aluminate.

[0039] In parts by weight, the pigment agent includes: 217-226 parts of R5566 titanium dioxide, 2.8-3.6 parts of 4920 iron yellow, and 0.2-0.4 parts of titanium cyan green.

[0040] A preparation method for high temperature resistant powder coatings, comprising the following steps in turn:

[0041] S1: raw material preparation; weigh 9090 polyester resin, TGIC curing agent, 6088 leveling agent, 701B brightener, benzoin, SA5066 hardening agent, pigment agent, SA5060 defoamer, and P600 calcium aluminate in parts by weight;

[0042] S2: pre-mixing; pre-mixing the prepared raw materials in a hi...

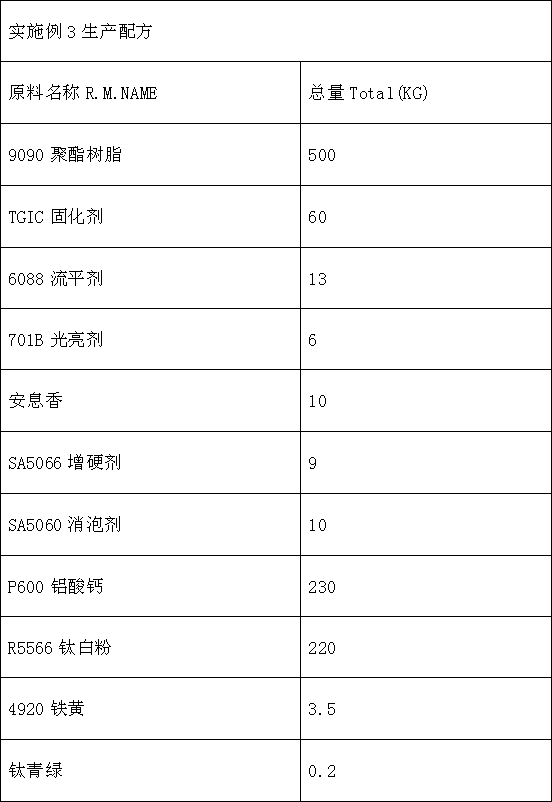

Embodiment 3

[0048]A high-temperature-resistant powder coating, in parts by weight, its raw material composition includes: 500 parts of 9090 polyester resin, 60 parts of TGIC curing agent, 13 parts of 6088 leveling agent, 6 parts of 701B brightener, 10 parts of benzoin, SA5066 9 parts of hard agent, 223.7 parts of pigment agent, 10 parts of SA5060 defoamer, 230 parts of P600 calcium aluminate.

[0049] In terms of parts by weight, the composition of the pigment agent includes: 220 parts of R5566 titanium dioxide, 3.5 parts of 4920 iron yellow, and 0.2 parts of titanium cyan green.

[0050] A preparation method for high temperature resistant powder coatings, comprising the following steps in turn:

[0051] S1: raw material preparation; weigh 9090 polyester resin, TGIC curing agent, 6088 leveling agent, 701B brightener, benzoin, SA5066 hardening agent, pigment agent, SA5060 defoamer, and P600 calcium aluminate in parts by weight;

[0052] S2: pre-mixing; pre-mixing the prepared raw material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com