Quantum dots and preparation method thereof

A technology of quantum dots and mass ratio, applied in the field of quantum dots and its preparation, can solve the problems of uneven particle size, high cost, and narrow particle size distribution of quantum dots, and achieve the effect of crushing effect, high efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] This embodiment provides a method for preparing ZnS quantum dots, the specific steps are as follows:

[0072] (1) Mix 1g of ZnS bulk material, 10g of sodium chloride and 10g of agate balls (0.5mm in diameter), ball mill for 0.5h, then separate the agate balls by sieving, and wash the sample repeatedly with deionized water until passing X X-ray photoelectron spectrometer (ESCALAB250Xi) can not detect the existence of chlorine element and sodium element, then dry, obtain crude product;

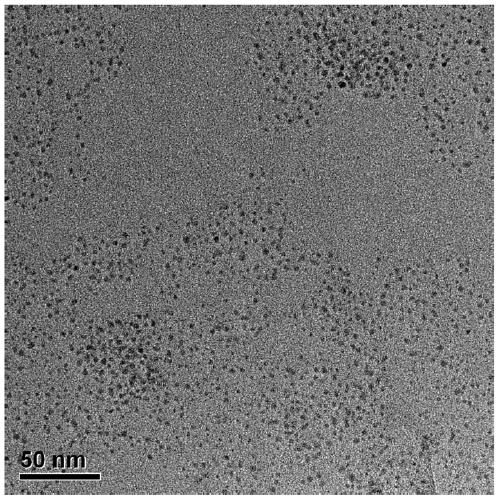

[0073] (2) Mix the crude product obtained in step (1) with water to obtain a mixed solution with a crude product concentration of 1 mg / mL, and ultrasonicate the mixed solution for 120 h at a power of 50 W; carry out vacuum filtration on the sample after ultrasonic, The aqueous dispersion of the ZnS quantum dots was obtained by passing through a filter membrane with a pore size of 0.02 μm.

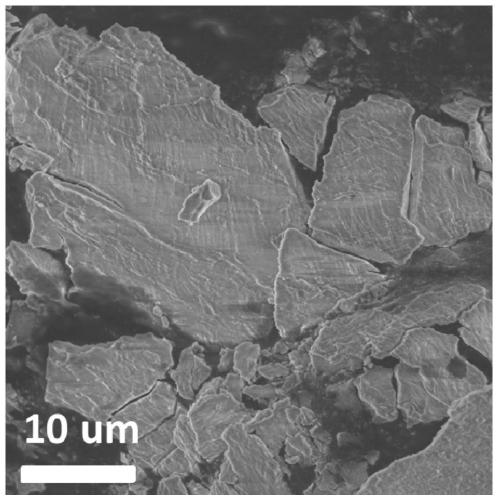

[0074] Test the surface morphology of the raw material ZnS bulk material used in this embodiment b...

Embodiment 2

[0077] This embodiment provides a method for preparing FeS quantum dots, the specific steps are as follows:

[0078] (1) Mix 1g of FeS bulk material, 10g of sodium chloride and 10g of agate balls, ball mill for 0.5h, then separate the agate balls by sieving, and wash the sample repeatedly with deionized water until passing through an X-ray photoelectron spectrometer ( ESCALAB250Xi) can not detect the existence of chlorine element and sodium element, dry afterwards, obtain crude product;

[0079] (2) Mix the crude product obtained in step (1) with water to obtain a mixed solution with a crude product concentration of 1 mg / mL, and ultrasonicate the mixed solution for 120 h at a power of 50 W; carry out vacuum filtration on the sample after ultrasonic, The aqueous dispersion of FeS quantum dots was obtained by passing through a filter membrane with a pore size of 0.02 μm.

[0080] The optical picture of the water dispersion liquid of the FeS quantum dot that the present embodime...

Embodiment 3

[0082] This embodiment provides a method for preparing Ag quantum dots, the specific steps are as follows:

[0083] (1) Mix 100mg of Ag bulk material, 10g of silica (400nm in particle size) and 10g of zirconia balls (0.5mm in diameter), ball mill for 0.5h, and then separate the zirconia balls by sieving to obtain crude product.

[0084] (2) Mix the crude product obtained in step (1) with N-methylpyrrolidone (NMP) to obtain a mixed solution with a crude product concentration of 5 mg / mL, and ultrasonicate the mixed solution for 120 h at a power of 50 W; The sample was vacuum filtered and passed through a filter membrane with a pore size of 0.02 μm to obtain the NMP dispersion of the Ag quantum dots.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com