U-shaped dual-drive dispersion strengthening reaction device

A dispersion strengthening and reaction device technology, which is applied in the petroleum industry, hydroprocessing process, and hydrocarbon oil treatment, can solve the problems that circulating oil cannot be realized, cannot run for a long period, and increase solid content, so as to overcome carbon-rich heavy components If the proportion is too high, the effect of increasing the macroscopic reaction rate and increasing the reaction volume space velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

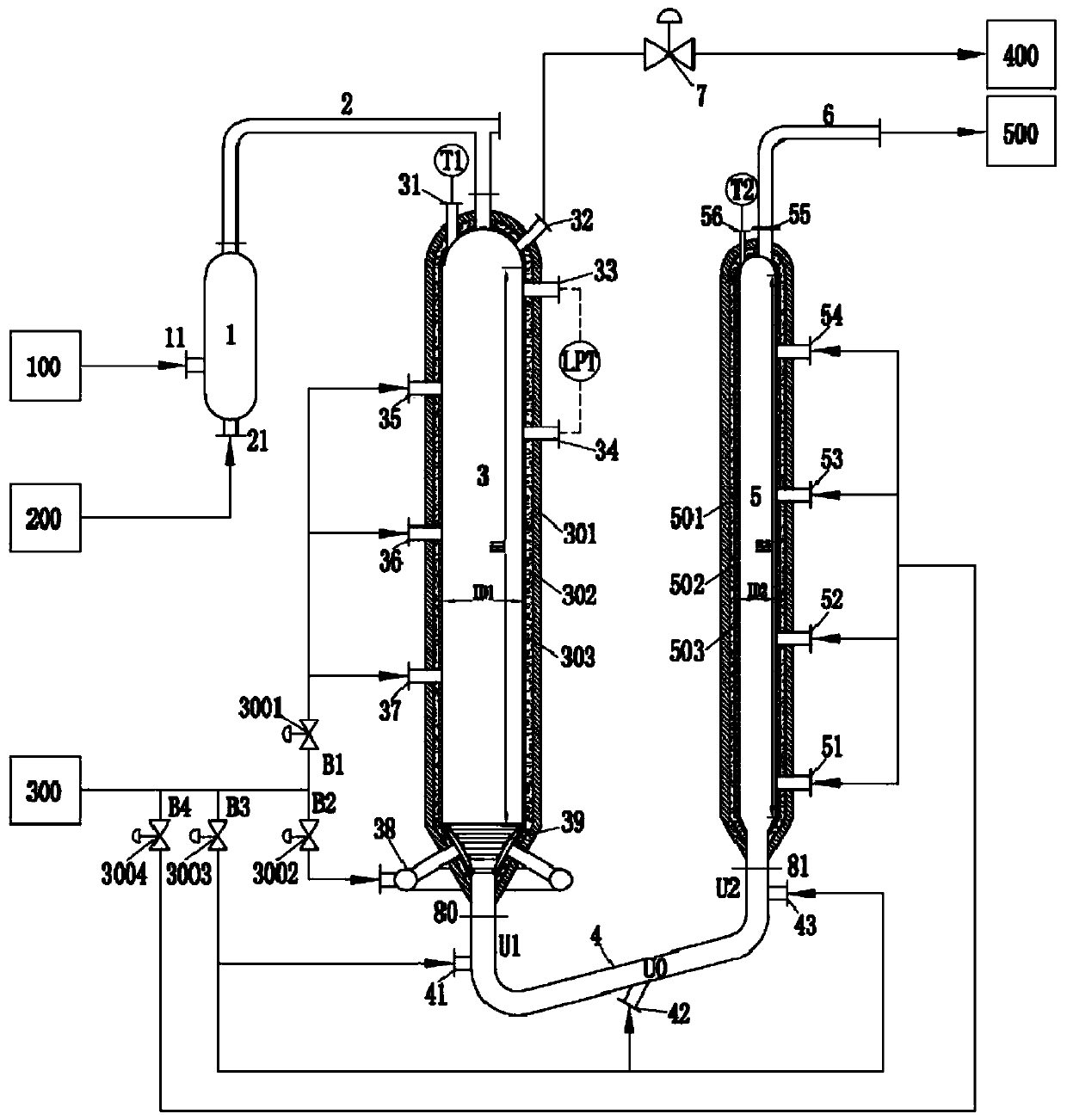

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0029] see figure 1, the reaction pressure of the present invention is 6.5~16.5MPa (G), and reaction temperature is 400~550 ℃, comprises that the middle and lower part is provided with the gas phase inlet 11 that links to each other with gas phase raw material 100, liquid phase raw material 200 and the servo of liquid phase inlet 21 respectively Drive 1, the liquid phase raw material 200 is one of residual oil to be converted, super heavy oil, heavy heavy oil, shale oil, oil sand bitumen, FCC oil slurry, coal tar, and oil-coal slurry with a solid content of 30-50%. One or more kinds of mixed feed, the top of the servo driver 1 is connected with the primary dispersion enhanced reactor 3 through the pipeline 2, and the primary dispersion enhanced reactor 3 is composed of an inner anti-corrosion layer 301, a middle transition layer 302 and an outer bearing Lami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com