Near-infrared transparent metal chalcogenide/carbon nanotube composite flexible film and preparation method thereof

A technology of carbon nanotube compounding and chalcogenides, which is applied in the direction of nanotechnology, thermoelectric device manufacturing/processing, thermoelectric device node lead-out materials, etc., can solve the problems of unstable adsorption and inability to accurately control the composition, and achieve optimization Thermoelectric performance, good bending and flexibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

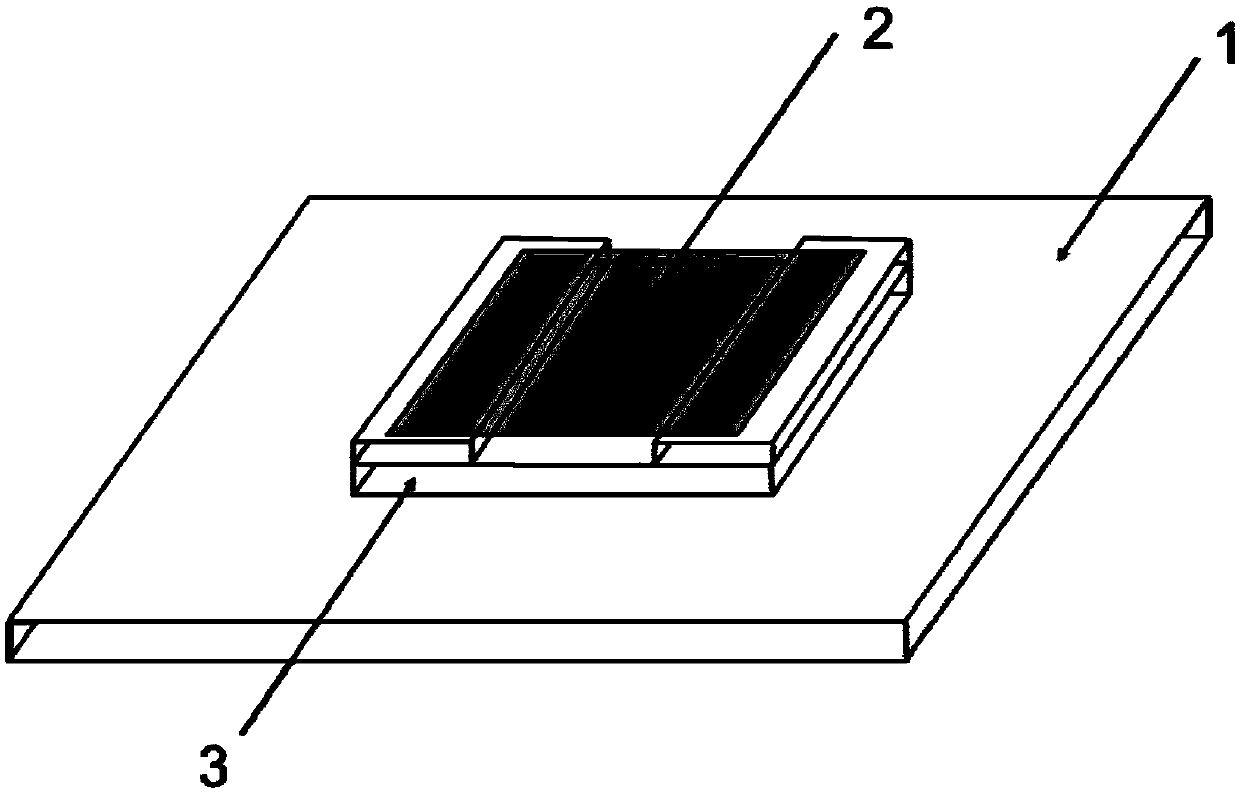

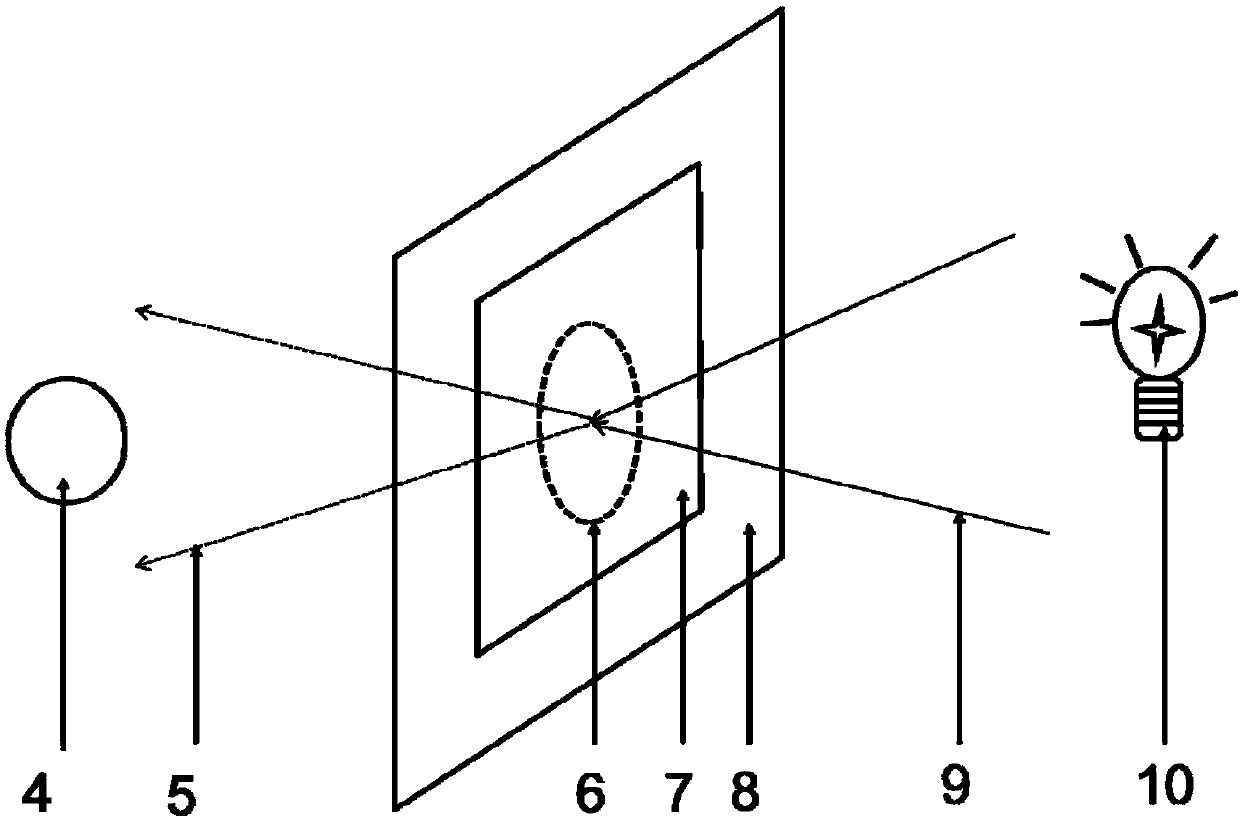

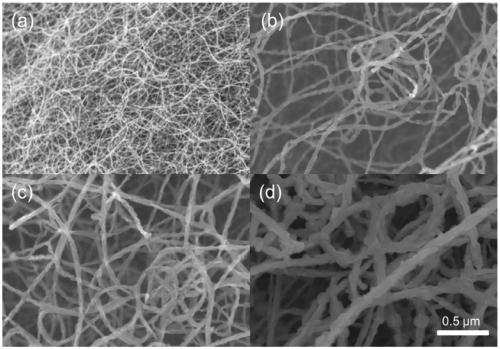

[0060]In this example, the preparation method of the two-dimensional infrared transparent flexible composite thermoelectric thin film that can be precisely adjusted, firstly transfer the SWCNT substrate with high flexibility and high infrared transparency to the pre-treated clean support material; then the support material Put the SWCNTs on the surface into a glove box and heat at 100-500°C to desorb oxygen and other impurities adsorbed on the SWCNTs; after cooling down to room temperature, put the desorbed SWCNTs into a high vacuum balance magnetron sputtering deposition In the cavity, the gas pressure in the high vacuum balance magnetron sputtering deposition cavity is (4~8)×10 -5 Start heating at Pa, when the temperature is 300-500°C, keep it warm for 1-3h, and pass high-purity argon gas with a volume purity of 99.99%, so that the gas pressure in the balanced magnetron sputtering deposition chamber is maintained at 0.5-2Pa. Hui began to prepare metal chalcogenide / single-wal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com