Lick-brick for buffalos during lactation period and preparation method therefor

A technology for licking bricks in lactation period, applied to the field of licking bricks in buffalo lactation period and its preparation, can solve problems such as affecting milk production rate, antibiotic residues, economic losses, etc., so as to improve immune disease resistance, prevent lactation mastitis, Reducing the effect of lactation mastitis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

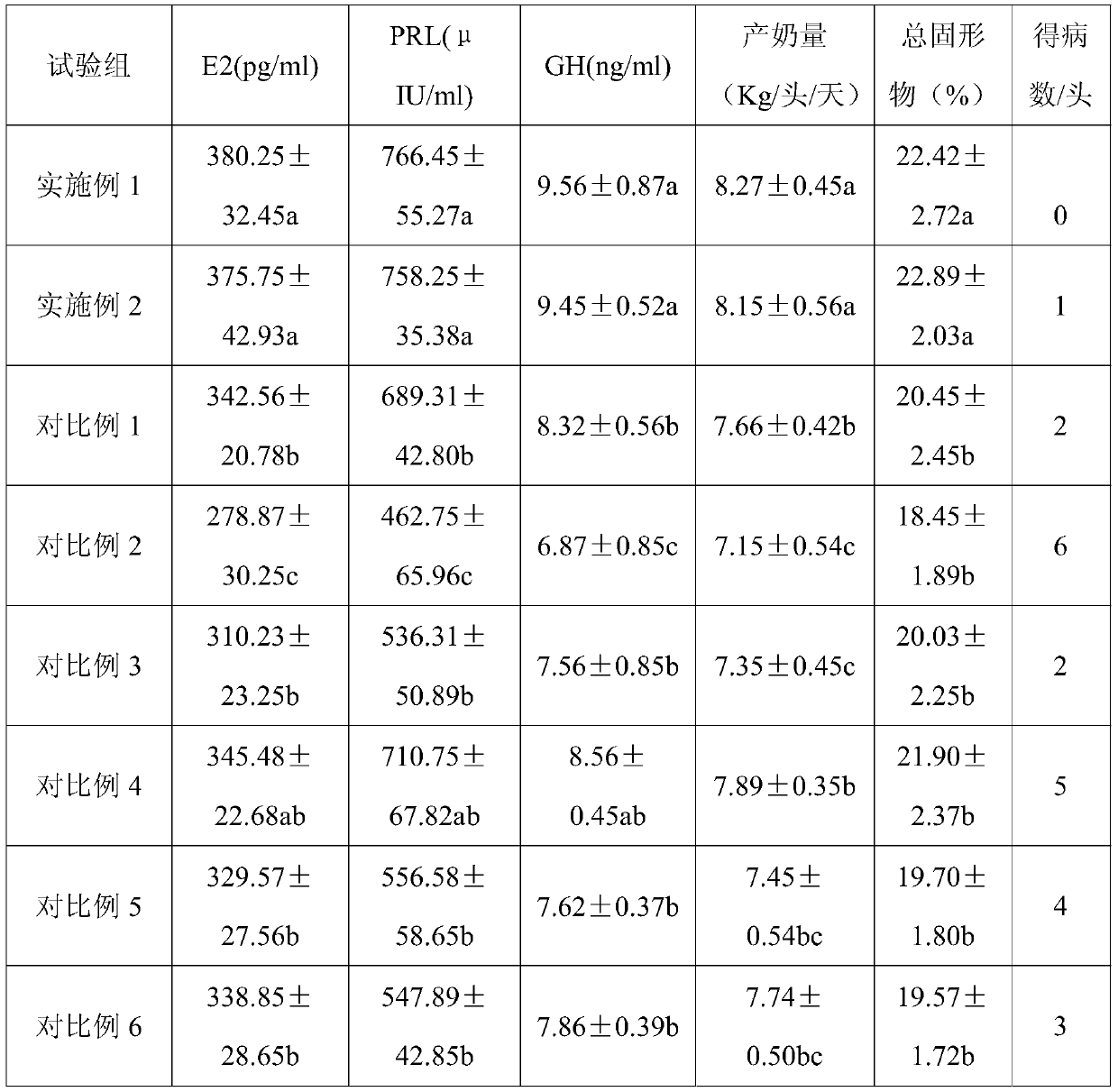

Examples

Embodiment 1

[0035] A buffalo licking brick during lactation, comprising the following raw materials in parts by weight: 1500 parts of molasses, 500 parts of urea, 1200 parts of wheat bran, 400 parts of cement, 350 parts of table salt, 600 parts of bentonite, 2.8 parts of ferrous sulfate heptahydrate, monohydrate 1.7 parts of manganese sulfate, 2.6 parts of zinc sulfate monohydrate, 0.3 parts of sodium selenite, 0.1 part of cobalt sulfate, 392.5 parts of anhydrous calcium hydrogen phosphate, 50 parts of multivitamins, 5 parts of lactoferrin, 8 parts of seaweed polysaccharide, yeast cell wall 6 parts of polysaccharide, 40 parts of plant extract.

[0036] The plant extracts include mulberry leaf extract, perilla extract, dandelion extract and astragalus extract. The plant extract comprises the following components according to mass fraction: 60% of mulberry leaf extract, 20% of perilla extract, 10% of dandelion extract and 10% of astragalus extract.

[0037] The effective components of the ...

Embodiment 2

[0045] A buffalo licking brick during lactation, comprising the following raw materials in parts by weight: 1700 parts of molasses, 400 parts of urea, 1500 parts of wheat bran, 300 parts of cement, 250 parts of table salt, 500 parts of bentonite, 3 parts of ferrous sulfate heptahydrate, monohydrate 1.5 parts of manganese sulfate, 3 parts of zinc sulfate monohydrate, 0.1 parts of sodium selenite, 0.2 parts of cobalt sulfate, 380 parts of anhydrous calcium hydrogen phosphate, 60 parts of multivitamins, 10 parts of lactoferrin, 5 parts of seaweed polysaccharide, yeast cell wall 10 parts of polysaccharide, 60 parts of plant extract.

[0046] The plant extracts include mulberry leaf extract, perilla extract, dandelion extract and astragalus extract. The plant extract comprises the following components according to mass fraction: 50% of mulberry leaf extract, 20% of perilla extract, 15% of dandelion extract and 15% of astragalus extract.

[0047] The effective components of the mul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com