A degradable metal cable internal fixation system and application

A fixation system, metal technology, applied in the direction of internal fixator, fixator, internal bone synthesis, etc., can solve the problems of non-degradable alloy cable, easy premature cable breakage, insufficient cable strength, etc., to reduce the stress shielding effect, reduce the Pain and economic burden, effects of good mechanical compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1: Degradable metal cable internal fixation system for phalangeal fractures

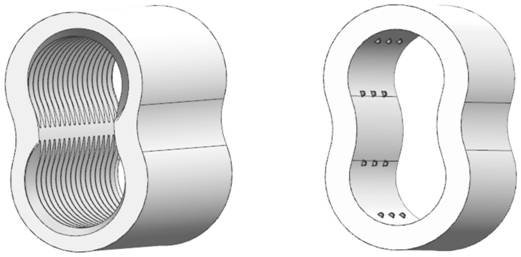

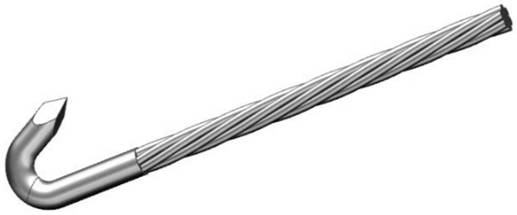

[0043] like Figure 7 As shown, the present invention provides a degradable metal cable internal fixation system for phalangeal fracture and a method of using the same, the cable internal fixation system includes a cable and a clamping buckle, and the above materials are all made of degradable pure magnesium. like figure 1 As shown, the structure of the cable is 3×7, and the mechanically combined end of the degradable metal cable adopts such as Image 6 Terminal D shown; figure 2 Pillow-shaped clamp shown with internal threads on the inner wall of the clamp; no lead pins attached to the cable.

[0044] During orthopaedic surgery, first insert the end of the cable without the mechanically combined end (hereinafter referred to as the moving end) into a through hole of the pillow-shaped clamping buckle, and move the clamping buckle to the side of the mechanically combined end of the...

Embodiment 2

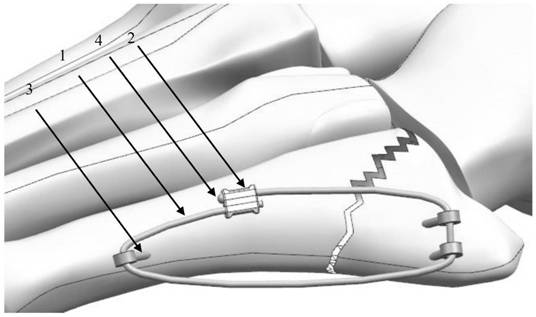

[0046] Example 2: Degradable metal cable internal fixation system for patella fractures

[0047] like Figure 8 As shown, the present invention provides a degradable metal cable internal fixation system for patella fracture and a method of using the same, the cable internal fixation system includes a cable, a lead pin and a clamping buckle, and the above materials are all made of degradable Mg- Preparation of Nd-Zn-Zr alloy. like figure 1 As shown, the structural formula of the cable is 7×7, and the mechanically combined end of the degradable metal cable adopts such as Image 6 Terminal B shown; Figure 4 The top-tight clamping buckle shown has teeth on the inner wall of the clamping buckle; Figure 5 Single-ended looper cable shown.

[0048] During orthopaedic surgery, first pass the movable end of the cable into one side through hole of the top-tight clamping buckle, and move the clamping buckle to the fixed end of the cable; then pass the movable end of the cable thr...

Embodiment 3

[0051] A degradable metal cable internal fixation system is different from Example 2 in that the structural formula of the cable is 7×19, and the technical effect evaluation is: the tensile strength of the cable is 440.3MPa, and the elongation after breaking is 4.9%; The corrosion rate of the corrosion test (immersed in Hank's solution for 10 days) was 0.24mm / y; the in vitro cell test (MTT method was used, the extraction ratio was 1.25cm) 2 / ml, L-929 cells, MEM containing 10% (V / V) calf serum) showed that the relative proliferation rate of cells in the experimental group was 89%, and the cytotoxicity was grade 1; the cable internal fixation system healed well after implantation, No ectopic or detached cables were found, and the complete degradation time was about 26 months.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com