Self-supporting sodium ion battery negative electrode material based on 3D printing and preparation method thereof

A sodium ion battery, 3D printing technology, applied in the direction of 3D object support structure, battery electrode, carbon preparation/purification, etc., can solve the problem of active material detached from the current collector, and achieve improved sodium storage performance, low energy consumption, and shape controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

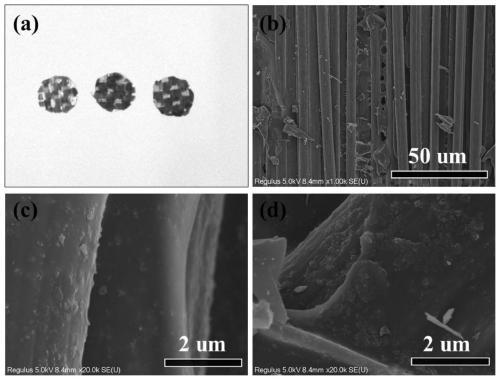

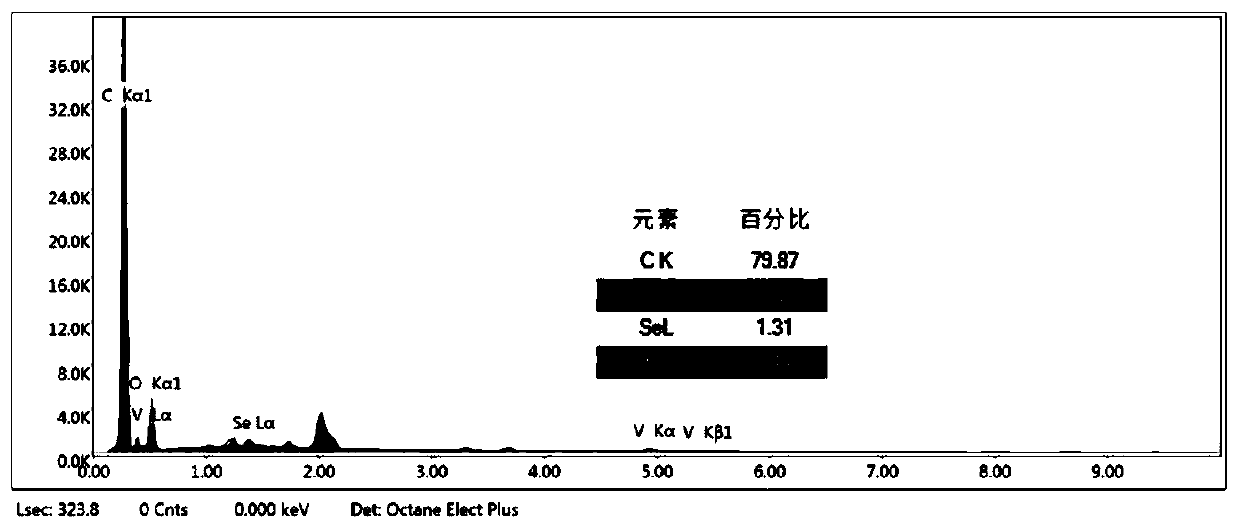

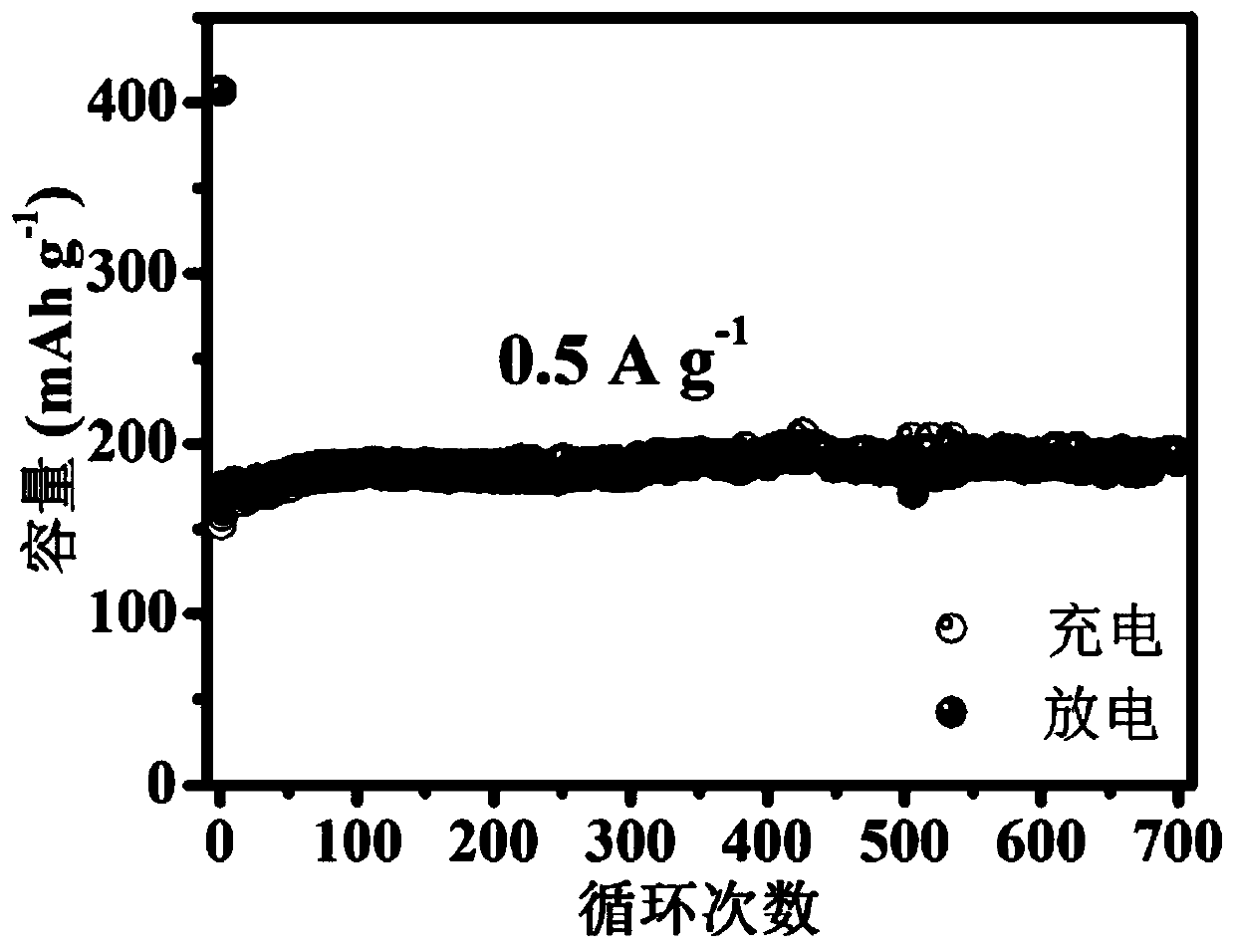

Examples

Embodiment 1

[0037] 1. A self-supporting sodium ion battery negative electrode material based on 3D printing, characterized in that it is made of the following components in weight percentage:

[0038] PLA40

[0039] Chlorella 58

[0040] white oil 2

[0041] 2. A method for preparing a self-supporting sodium-ion battery negative electrode material based on 3D printing, comprising the following steps:

[0042] A. After mixing PLA, pellets and white oil in the formula quantity, melt and extrude granulation through twin-screw extruder. The process parameters of twin-screw extruder are 123, 135, 142, 160, 166, 170 , 170, 165, 155, 140 ℃, die head temperature is 170 ℃, screw speed is 50 rpm;

[0043] B. Pull the obtained pellets into 3D printing wire through a single-screw wire extruder. The process parameters of the single-screw wire extruder are the processing temperature of 180°C, the screw speed of 20 rpm, and the water temperature of the first stage of water cooling is 40°C; the second...

Embodiment 2

[0050] 1. A self-supporting sodium ion battery negative electrode material based on 3D printing, characterized in that it is made of the following components in weight percentage:

[0051] ABS50

[0052] Chlorella 49

[0053] white oil 1

[0054] 2. A method for preparing a self-supporting sodium-ion battery negative electrode material based on 3D printing, comprising the following steps:

[0055] A. After mixing the ABS, pellets and white oil in the formula amount, melt and extrude the pellets through the twin-screw extruder. The process parameters of the twin-screw extruder are 130, 145, 152, 170, 186, 200 , 200, 195, 190, 185 ℃, the die head temperature is 180 ℃, the screw speed is 80 rpm;

[0056] B. Pull the obtained pellets into 3D printing wire through a single-screw wire extruder. The process parameters of the single-screw wire extruder are the processing temperature of 200°C, the screw speed of 20 rpm, and the water temperature of the first stage of water cooling i...

Embodiment 3

[0062] 1. A self-supporting sodium ion battery negative electrode material based on 3D printing, characterized in that it is made of the following components in weight percentage:

[0063] TPU / ABS(50wt%:50wt%) 38

[0064] Chlorella 59

[0065] white oil 3

[0066] 2. A method for preparing a self-supporting sodium-ion battery negative electrode material based on 3D printing, comprising the following steps:

[0067] A. After mixing the TPU / ABS (50wt%:50wt%), pellets and white oil of the formula amount, the twin-screw extruder is melted and extruded to granulate. The twin-screw extruder process parameters are that the temperature of each section is 130, 145, 150, 165, 180, 190, 190, 185, 180, 180°C, die head temperature is 170°C, screw speed is 60 rpm;

[0068] B. Pull the obtained pellets into 3D printing wire through a single-screw wire extruder. The process parameters of the single-screw wire extruder are processing temperature 190°C, screw speed 30 rpm, and water temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com