Soft magnetic Co-based bulk amorphous alloy with high saturation induction density and preparation method of amorphous alloy

A magnetic induction strength, amorphous alloy technology, applied in the direction of magnetic objects, magnetic materials, metal processing equipment, etc., can solve the problems of difficult amorphous formation ability and high cost of alloys, and achieve low preparation cost, low raw material cost, and low Hc Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention also provides a method for preparing the above-mentioned soft magnetic Co-based bulk amorphous alloy with high saturation magnetic induction, comprising the following steps:

[0040] Step 1: Ingredients

[0041] Select Co, Fe, Ni, Si, B, C and FeP alloy raw materials with a purity higher than 99% and weigh the ingredients according to the alloy composition ratio;

[0042] Step 2: Master alloy ingot smelting

[0043] Put the mixed raw materials weighed in step 1 into the crucible of the induction melting furnace, and smelt in an argon or nitrogen atmosphere to obtain a master alloy ingot with uniform composition; The master alloy ingot is obtained by smelting in an arc furnace under an atmosphere of argon or nitrogen;

[0044] Step 3: Preparation of bulk amorphous alloy

[0045] The master alloy ingot is crushed and put into a quartz tube, and the block sample is prepared by copper mold casting method, that is, the master alloy ingot is first hea...

Embodiment 1

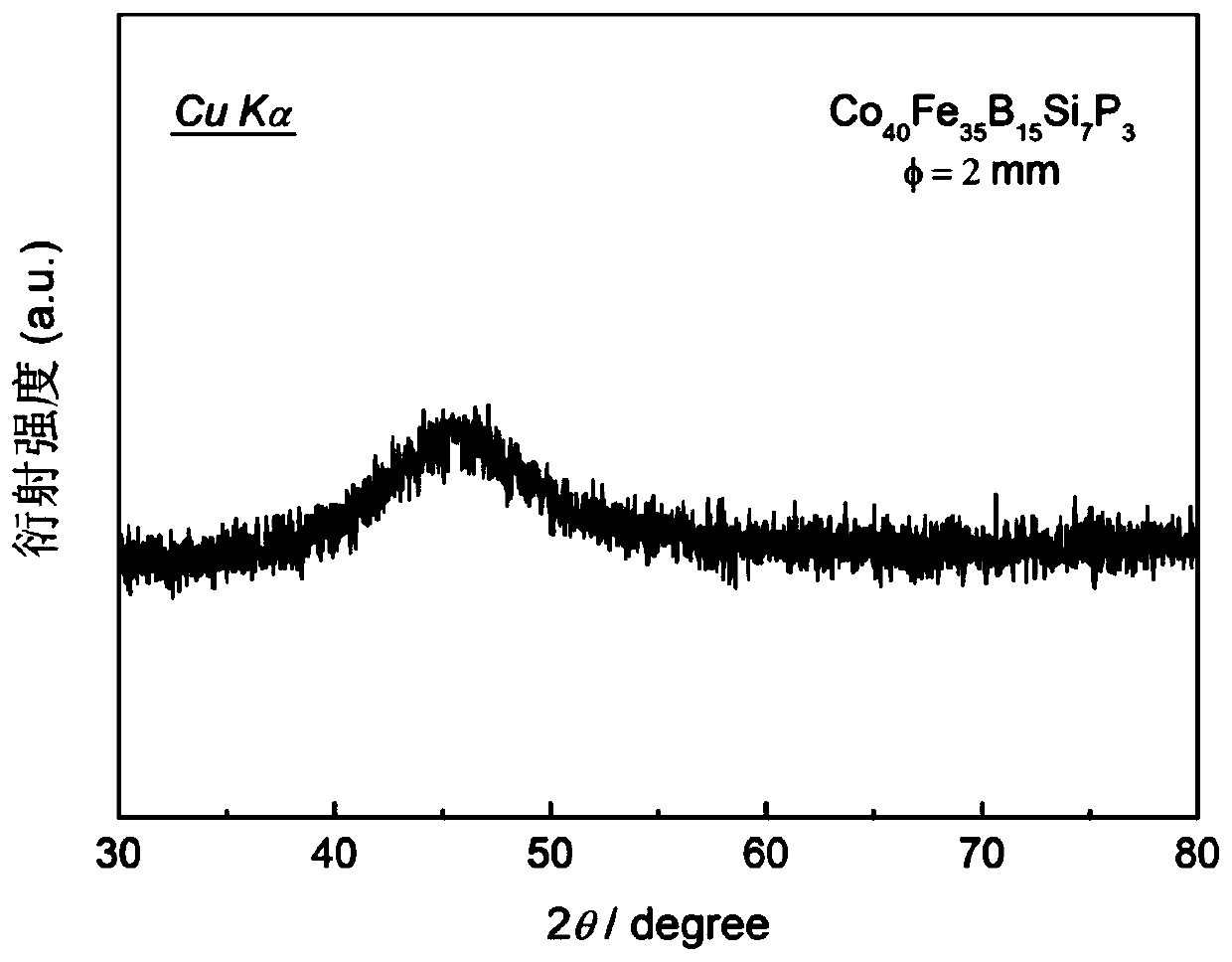

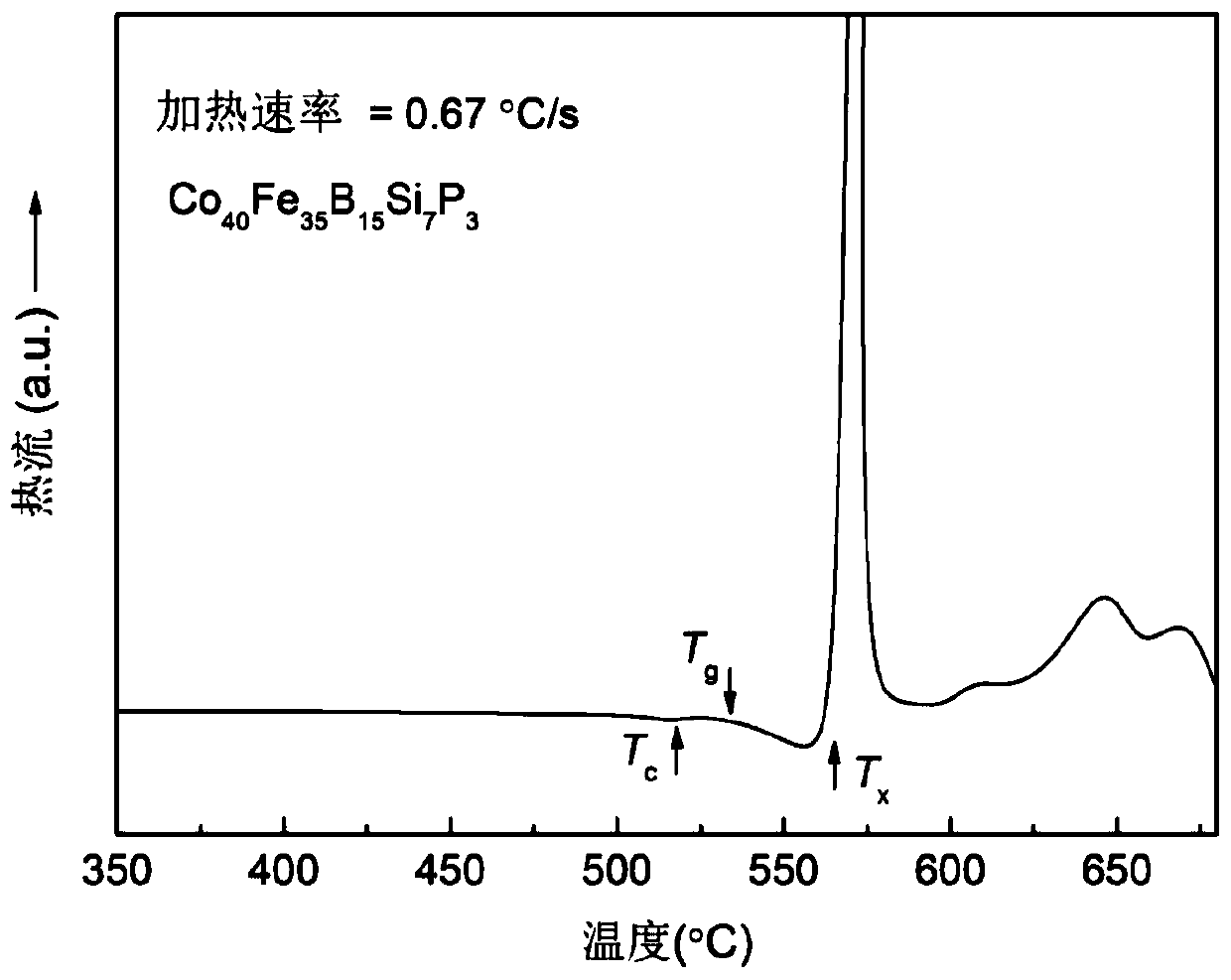

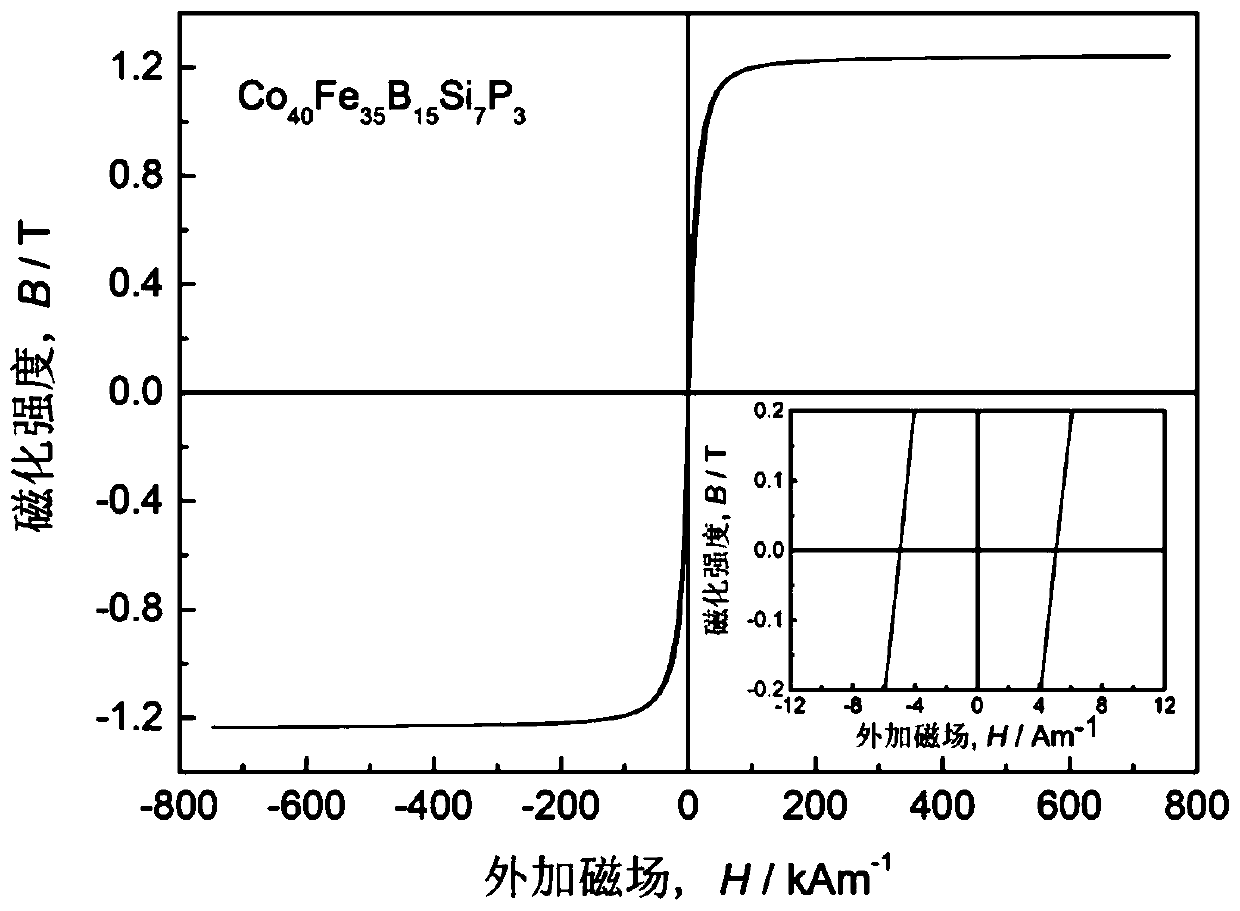

[0047] Example 1: Co 40 Fe 35 B 15 Si 7 P 3

[0048] Step 1: Ingredients

[0049] Select Co, Fe, B, Si and Fe with a purity higher than 99% 3 P alloy raw materials are weighed and proportioned according to the alloy composition ratio;

[0050] Step 2: Prepare master alloy ingot

[0051] Put the mixed raw material weighed in step 1 into a graphite crucible placed in a vacuum induction melting furnace, and melt it under an argon or nitrogen atmosphere to obtain a master alloy ingot with uniform composition;

[0052] Step 3: Preparation of Amorphous Strips

[0053] The master alloy ingot was crushed and loaded into a quartz tube, and the quenched strip sample was prepared by the single-roll strip stripping method. That is, in an argon or nitrogen atmosphere, the master alloy ingot is first heated to a molten state by induction melting, and then the alloy melt is sprayed onto a high-speed rotating copper roller with a high-pressure gas. The copper roller line speed is abo...

Embodiment 2

[0060] Example 2: Co 50 Fe 25 B 15 Si 7 P 3

[0061] Step 1: Select Co, Fe, Si, B and Fe with a purity higher than 99% 3 Raw materials such as P alloy are weighed and proportioned according to the alloy composition ratio.

[0062] Steps 2, 3, 4, 5, and 6 are the same as in Example 1, and an amorphous rod with a diameter of 1.5 mm is finally obtained. Its performance data are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| compressive yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com