Anti-capillary cable and preparation method thereof

A capillary action, cable technology, applied in cable/conductor manufacturing, insulating cables, insulating conductors/cables, etc., can solve the problems affecting the normal trial of other components or components of the cable, achieve large-scale continuous industrial production, avoid equipment The effect of using failure problems and avoiding media contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The silicone resin in this example is polymethyl silicone resin, and the viscosity is not less than 12s when tested according to GB / T 1723-93 design at 25°C.

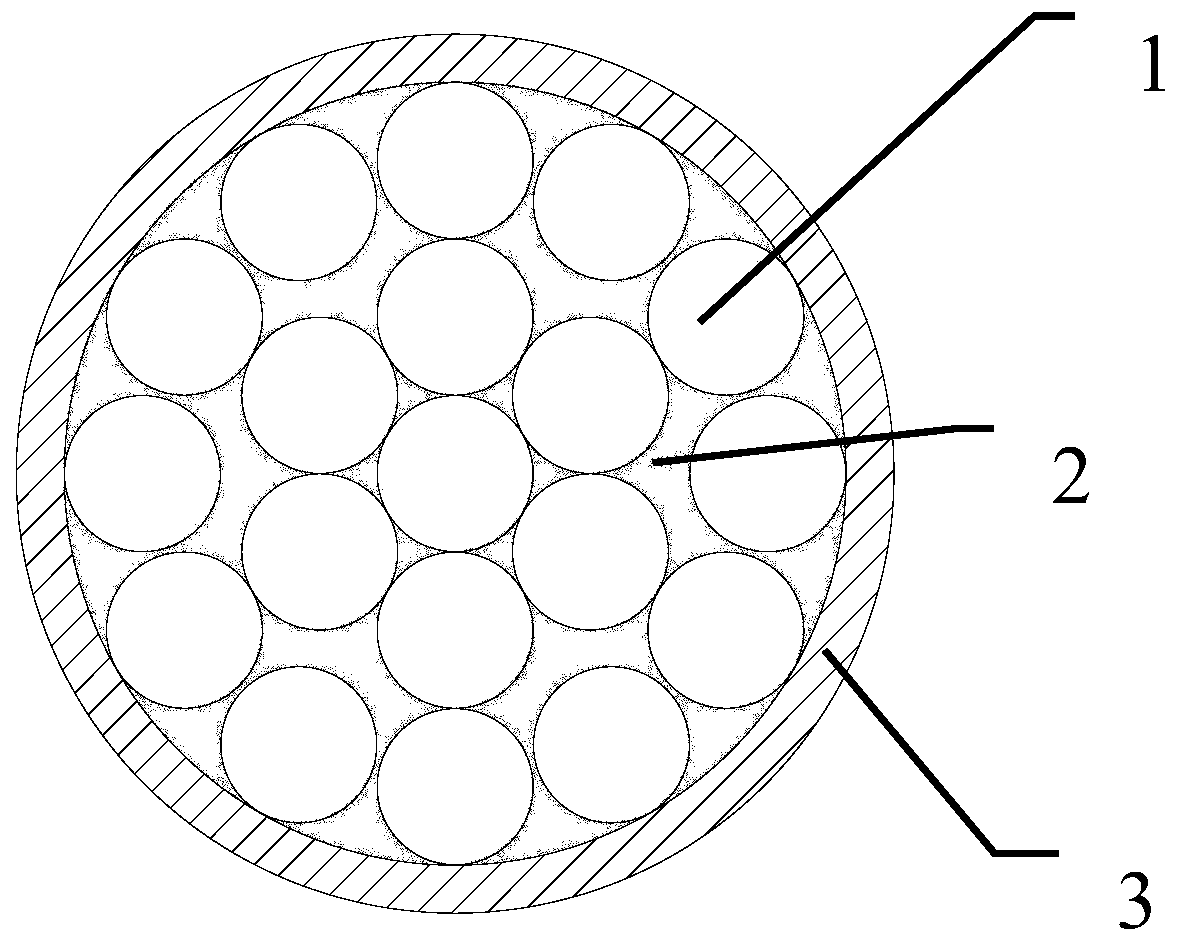

[0037] Tin-plated copper monofilament conductors are used, the conductors are passed through and immersed in silicone resin, and then stranded, and the excess silicone resin is removed through the mold, and the 19 stranded conductors are reeled after being baked at 175°C, and processed at 175°C The time can be determined according to specific needs, and it is specifically 10 minutes in this embodiment. Place the coiled stranded conductor in an oven at 200°C for 2 hours to fully cure the silicone resin;

[0038] The insulation is then applied through wire extrusion equipment. The insulating material is ethylene-tetrafluoroethylene (X-ETFE) crosslinked by radiation, the extrusion temperature is 260°C, and the insulation thickness is 0.2mm. The extruded cable is irradiated and crosslinked by an electron accelerator...

Embodiment 2

[0040] The epoxy resin in this embodiment adopts glycidyl ether epoxy resin, and its dynamic viscosity at 25°C is 500-1000mPa. s, the glass transition temperature after curing is 250°C to 280°C.

[0041] Silver-plated copper monofilament conductors are used, 19 conductors are stranded after being passed through epoxy resin, and the stranded conductors are pultruded through a 180°C forming die, and cross-linked and vulcanized for 3 hours after adding a 200°C hot oven to achieve sufficient degree of solidification, and finally cooling and winding;

[0042] Then the insulation layer is covered by wire extrusion equipment. The raw material component in the insulation layer is polyphenylene sulfide, the extrusion temperature is 300°C, and the insulation thickness is 0.3mm.

Embodiment 3

[0044] The dynamic viscosity of the liquid silicone rubber in this example is 6000-8000mPa at 25°C. s.

[0045] Tin-plated copper monofilament conductors are used, and the sealing material is conductive liquid silicone rubber with graphene added. The amount of graphene added is 20wt% of the total weight of the sealing material layer, and 19 conductors are passed through the raw material components of the conductive liquid silicone rubber sealing material. After stranding, excess conductive liquid silicone rubber is removed by passing through the mold, and the twisted conductor is wound up after being baked at 175°C. Place the coiled stranded conductor in an oven at 200°C for 2 hours to fully vulcanize the conductive liquid silicone rubber.

[0046] Then the insulating layer is covered by wire extrusion equipment. The insulating material in the insulating layer is irradiated cross-linked ethylene-tetrafluoroethylene (X-ETFE). The extrusion temperature is 300°C and the insulati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic viscosity | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com