Carbon composite material, mixed paste, battery and preparation method

A technology of carbon composite materials and mixed liquids, applied in chemical instruments and methods, carbon compounds, battery electrodes, etc., can solve the problems of poor conductivity of activated carbon, irreversible adsorption of lignin, etc., reduce adsorption, improve high-rate charge and discharge performance and Effect of cycle life and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A method for preparing a carbon composite material, comprising the steps of:

[0034] Step 1. Dissolving or melting the sugar into a liquid;

[0035] Step 2. Weigh a certain amount of graphite, place it in the liquid, stir and soak it, and prepare a mixed solution;

[0036] Step 3. Prepare the carbon composite material from the mixture by spray carbonization.

[0037] In step 1, the sugar is monosaccharide or polysaccharide, and the monosaccharide or polysaccharide is dissolved in water or directly heated to a molten state or dissolved in lye or acid solution, and continuously stirred under the action of a stirrer until completely dissolved. Monosaccharides are glucose, fructose, etc.; polysaccharides are sugars such as sucrose and maltose; the preferred one is sucrose, which has abundant yield and low cost.

[0038] The lye is sodium hydroxide or potassium hydroxide solution, the acid solution is dilute sulfuric acid or dilute nitric acid, and the water is pure water...

Embodiment 1

[0051] 1. Weigh 100g of sucrose with an analytical balance, then add 1000g of pure water and stir until completely dissolved, add 100g of flake graphite (the particle size of flake graphite is 12-50um) into the solution until fully mixed, soak for 24 hours, and obtain a mixed solution.

[0052] 2. The above mixed liquid is atomized by the spray carbonization method, transported to a high-temperature tube furnace through a nitrogen gas flow at 900°C for carbonization treatment, then cooled and collected, washed with pure water for several times, and dried at 100°C to prepare a carbon composite material (1).

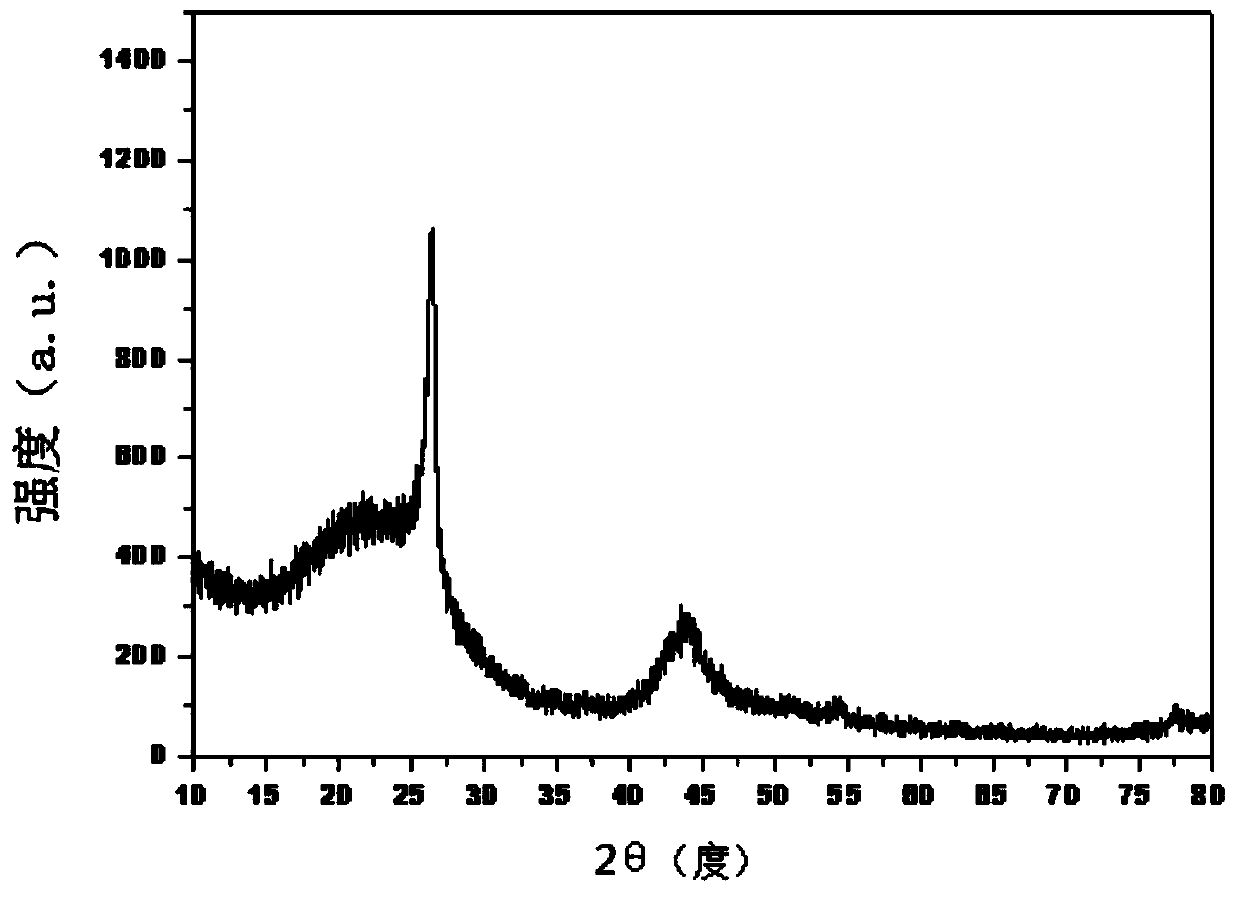

[0053] figure 1 It is the XRD pattern of the carbon composite material (1), and it can be seen from the figure that the characteristic peaks of activated carbon appear at the positions of 2θ=26.21° and 43.51°. At the same time, a strong diffraction peak of graphite (002) appears at the position of 2θ angle of 26.5°, with high intensity and small half-peak width. The prepa...

Embodiment 2

[0055] 1. Weigh 50g of sucrose with an analytical balance, then add 1000g of pure water and stir until completely dissolved, add 100g of spherical graphite (the particle size of spherical graphite is 7-20um) into the solution until fully mixed, soak for 36 hours, and obtain a mixed solution.

[0056] 2. The above-mentioned mixed liquid is atomized by spray carbonization method, and transported to a high-temperature tube furnace by nitrogen gas flow for carbonization treatment at 1000°C. Then it was collected under cooling, washed several times with pure water and dried at 100°C. A carbon composite material (2) is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com