Supported single-layer and few-layer two-dimensional transition metal sulfide catalyst and preparation method thereof

A transition metal and sulfide technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems affecting activity, achieve mild conditions, improve dispersion, and avoid shielding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

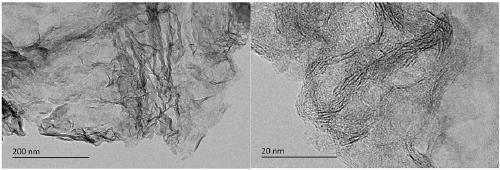

[0028] Weigh 50mg of graphene oxide, add 50ml of deionized water, and ultrasonically disperse to obtain a dispersion of graphene oxide; add 0.035mmol of ammonium paratungstate and 2.1mmol of glutathione under stirring and dissolve; transfer the resulting solution to a 100ml high-pressure reactor , hydrothermally reacted at 200°C for 12h, cooled and filtered with suction, the precipitate was washed with deionized water and then dried in vacuum at 80°C overnight to obtain a black powder product. XRD characterization results show that the obtained product contains tungsten disulfide phase. TEM images (see figure 1 ) shows that tungsten disulfide presents a sheet-like structure with mostly less than 5 layers, and is more uniformly loaded on the carrier sheet. The obtained materials are supported single-layer and few-layer two-dimensional transition metal sulfide catalysts.

Embodiment 2

[0030] Weigh 80mg g-C 3 N 4 , add 50ml deionized water, ultrasonically disperse to obtain g-C 3 N 4 Add 0.035mmol ammonium paratungstate and 2.1mmol glutathione under stirring and dissolve; transfer all the obtained solution to a 100ml high-pressure reactor, react with water at 240°C for 12h, suction filter after cooling, and use deionized water for precipitation After washing, it was vacuum dried overnight at 80° C. to obtain a black powder product. XRD characterization results showed that the obtained product contained tungsten disulfide. TEM images show that tungsten disulfide presents a lamellar structure of 2-4 layers loaded on the carrier. The obtained materials are supported single-layer and few-layer two-dimensional transition metal sulfide catalysts.

Embodiment 3

[0032]Weigh 50mg of graphene oxide, add 50ml of deionized water, add 0.06mmol of ammonium metavanadate and 2.1mmol of glutathione under stirring and dissolve; transfer all the obtained solution to a 100ml autoclave for hydrothermal reaction at 180°C After cooling for 12 hours, filter with suction, wash the precipitate with deionized water and dry it under vacuum at 70°C overnight to obtain a black powder product. XRD characterization results showed that the obtained product contained vanadium disulfide. TEM images show that tungsten disulfide presents a lamellar structure of 2-4 layers loaded on the carrier. The obtained materials are supported single-layer and few-layer two-dimensional transition metal sulfide catalysts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com