Molybdenum-modified Fe-ZSM5 molecular sieve catalyst as well as preparation method and application thereof

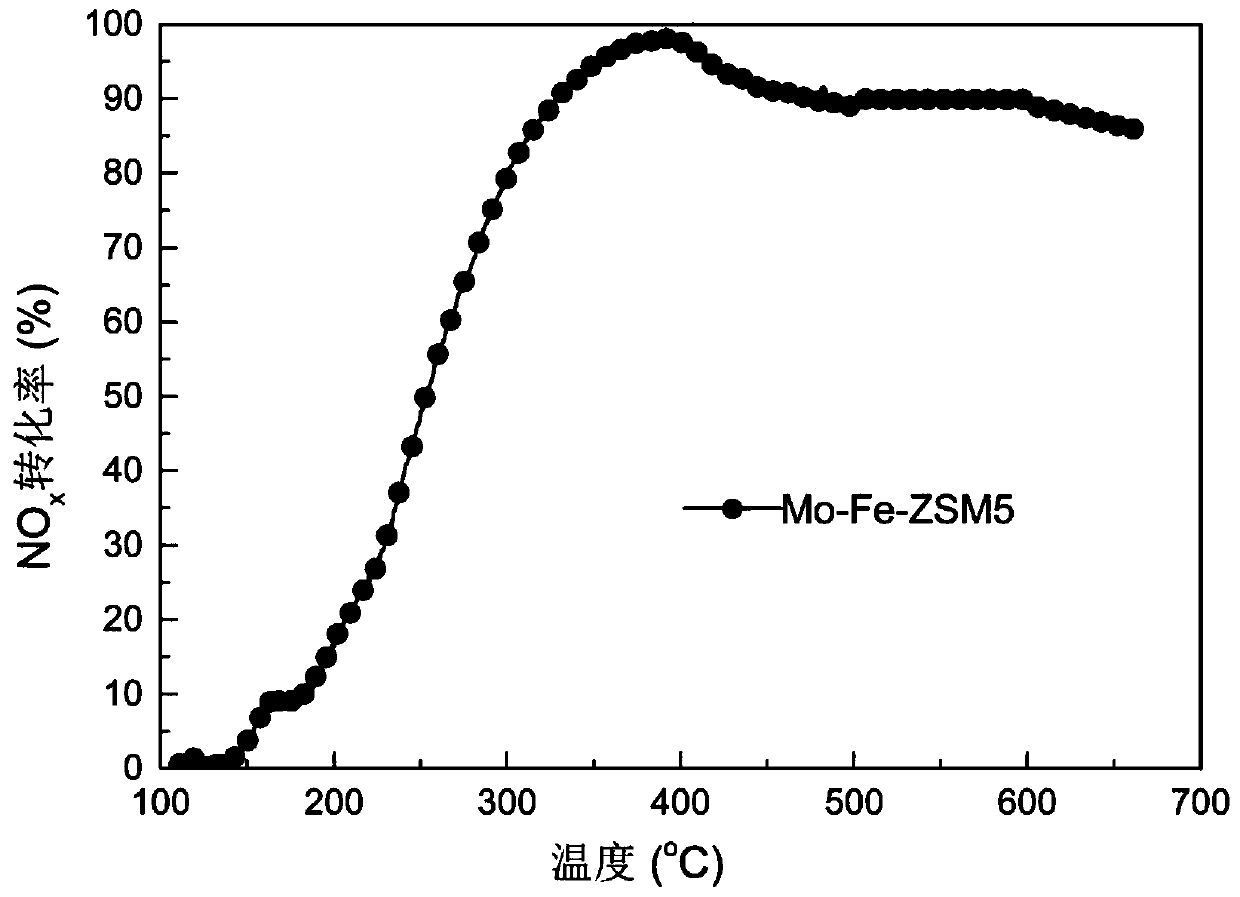

A molecular sieve and catalyst technology, applied in the field of selective reduction catalyst and its preparation, can solve the problems of insufficient low-temperature catalytic activity, poor hydrothermal aging resistance, poor SCR activity, etc., and achieve good anti-sulfur dioxide poisoning performance, performance improvement, and performance optimization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A molybdenum-modified Fe-ZSM5 molecular sieve selective reduction catalyst is prepared by the following method:

[0038] (1) Preparation of hydrogen-type molecular sieve: 50.0g of Na-ZSM5 molecular sieve with a silicon-aluminum ratio of 60mol:1mol and 1000ml of 0.5mol.L -1 NH 4 NO 3 The solution was ion-exchanged at 80°C for 2 hours, repeated twice, filtered, washed three times, dried at 100°C for 24 hours, and calcined at 550°C for 3 hours to obtain hydrogen molecular sieves.

[0039] (2) Preparation of Fe-ZSM5 molecular sieve: Weigh about 40.0g of the hydrogen-type molecular sieve prepared in step (1) and add it to 60ml0.2mol.L -1 Fe(NO 3 ) 2 In the solution, ion exchange was carried out in a water bath at 80°C for 3 hours, and repeated once, filtered and washed three times, dried at 120°C for 20 hours, and calcined at 500°C for 2 hours to obtain Fe-ZSM5 molecular sieves.

[0040] (3) Preparation of molybdenum-modified Fe-ZSM5 molecular sieve: 0.6g of lanthanum o...

Embodiment 2

[0050] A molybdenum-modified Fe-ZSM5 molecular sieve selective reduction catalyst is prepared by the following method:

[0051] (1) Preparation of hydrogen-type molecular sieve: 50.0g of Na-ZSM5 molecular sieve with a silicon-aluminum ratio of 60mol:1mol and 1000ml of 0.5mol.L -1 NH 4 NO 3 The solution was ion-exchanged twice for 2 hours in a water bath at 80°C, filtered, washed three times, dried at 110°C for 36 hours, and calcined at 500°C for 4 hours to obtain a hydrogen molecular sieve.

[0052] (2) Preparation of Fe-ZSM5 molecular sieve: Weigh 50.0 g of hydrogen ZSM5 molecular sieve prepared in step (1) and add to 60ml0.4mol.L -1 Fe(NO 3 ) 2 In the solution, ion exchange was carried out in a water bath at 60°C for 3 hours, repeated once, filtered, washed 3 times, dried at 120°C for 20 hours, and calcined at 500°C for 3 hours to obtain Fe-ZSM5 molecular sieve.

[0053] (3) Preparation of molybdenum modified Fe-ZSM5 molecular sieve: add 0.5g lanthanum oxide to 60ml 0.2...

Embodiment 3

[0056] A molybdenum-modified Fe-ZSM5 molecular sieve selective reduction catalyst is prepared by the following method:

[0057] (1) Preparation of hydrogen-type molecular sieve: 50.0g of Na-ZSM5 molecular sieve with a silicon-aluminum ratio of 80mol:1mol and 1200ml of 0.4mol.L -1 NH 4 NO 3 The solution was ion-exchanged at 80°C for 2 hours twice, filtered, washed three times, dried at 100°C for 24 hours, and calcined at 550°C for 5 hours to obtain hydrogen molecular sieves.

[0058] (2) Preparation of Fe-ZSM5 molecular sieve: Weigh about 50.0g of the hydrogen-type ZSM5 molecular sieve prepared in step (1) and add it to 60ml 0.4mol.L -1 Fe(NO 3 ) 2 In the solution, ion exchange was carried out in a water bath at 75°C for 3h, repeated once, filtered, washed three times, dried at 130°C for 20h, and calcined at 500°C for 3h to obtain Fe-ZSM5.

[0059] (3) Preparation of molybdenum modified Fe-ZSM5 molecular sieve: add 0.6g lanthanum oxide to 60ml 0.1mol.L -1 Ammonium molybda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com