Method for treating industrial catalytic waste copper acetylide

A waste, copper acetylene technology, applied in the direction of solid waste removal, etc., to achieve the effect of life safety protection, avoid pollution and damage, and improve the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

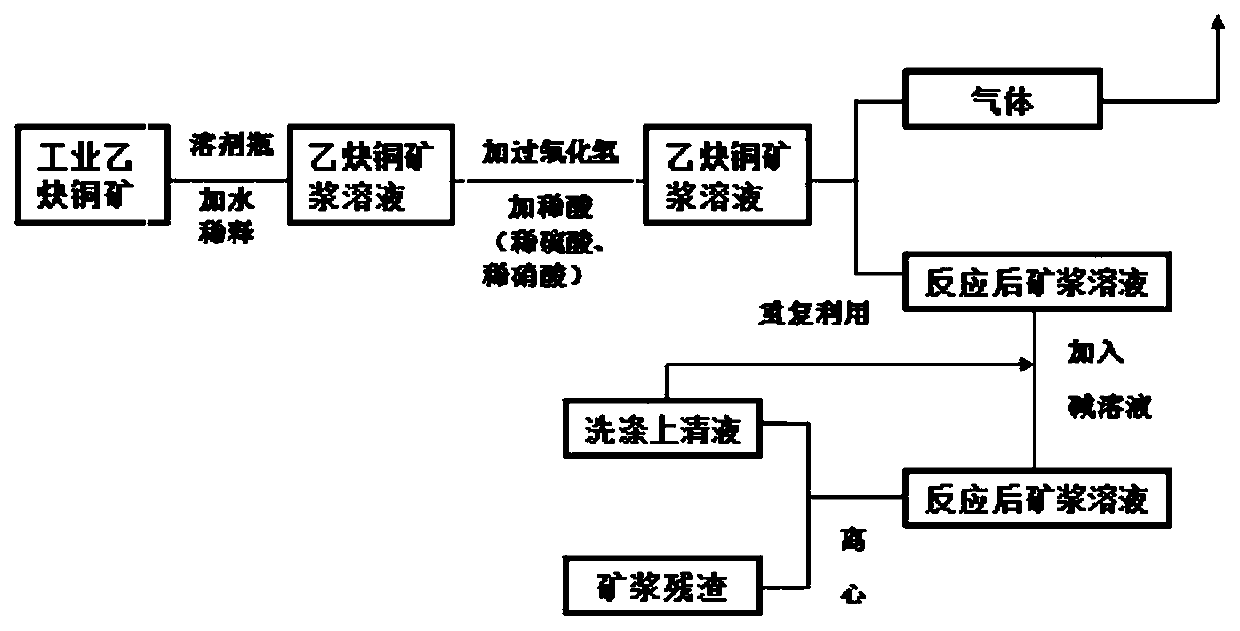

Method used

Image

Examples

Embodiment 1

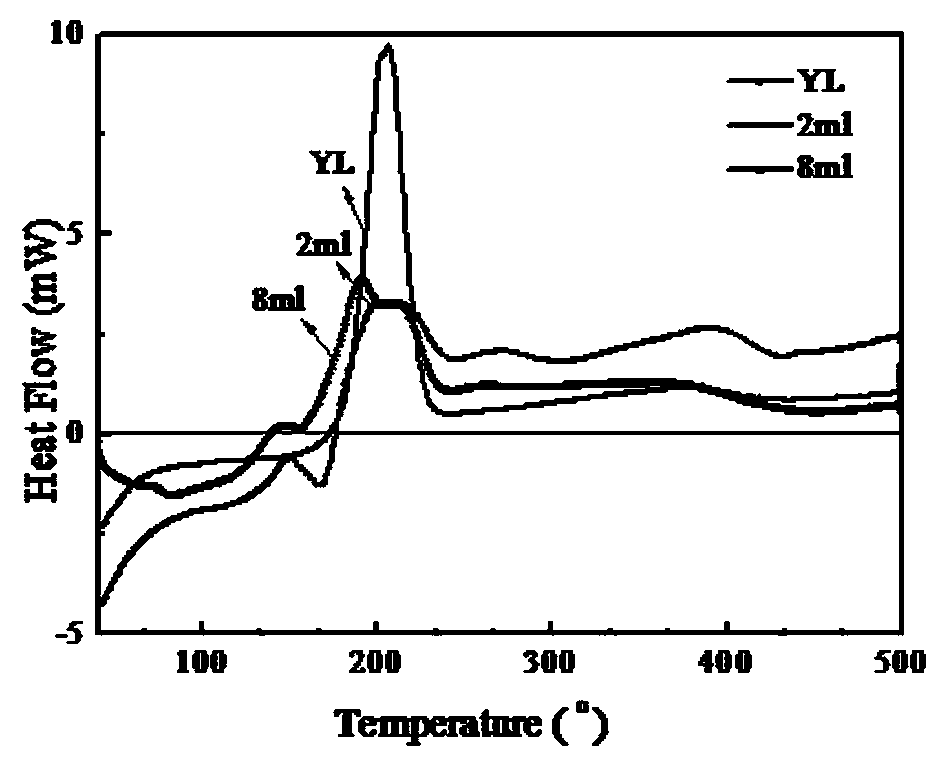

[0025] A. Weigh 10g of acetylene copper ore slurry, put it in a container, add 10g of distilled water, and stir evenly. Add 2ml of hydrogen peroxide and stir evenly, quickly add 2ml of prepared dilute sulfuric acid (S2) into the container, stir in an oil bath, and react at room temperature for 5h. Reactive gases were collected with gas bags. After the reaction, the pH value was adjusted to 11-12 with NaOH, and then the residue after the reaction was centrifuged, washed three times, and dried at 60° C. to obtain the residue sample M2.

[0026] B. Weigh 10g of acetylene copper ore slurry, put it in a container, add 10g of distilled water, and stir evenly. Add 2ml of hydrogen peroxide and stir evenly, quickly add 4ml of prepared dilute sulfuric acid (S4) into the container, stir in an oil bath, and react at room temperature for 5h. Reactive gases were collected with gas bags. After the reaction, the pH value was adjusted to 11-12 with NaOH, and then the residue after the react...

Embodiment 2

[0035] A. Weigh 10g of acetylene copper ore slurry, put it in a container, add 10g of distilled water, and stir evenly. Add 2ml of hydrogen peroxide and stir evenly, add 5ml of prepared dilute nitric acid (S5) into the container, stir in an oil bath, and react at room temperature for 5h. Reactive gases were collected with gas bags. After the reaction, the pH value was adjusted to 11-12 with NaOH / KOH, the residue after the reaction was centrifuged, washed three times, and dried at 60° C. to obtain the residue sample M5.

[0036]B. Weigh 10g of acetylene copper ore slurry, put it in a container, add 10g of distilled water, and stir evenly. Add 2ml of hydrogen peroxide and stir evenly, add 10ml of prepared dilute nitric acid (S10) into the container, stir in an oil bath, and react at room temperature for 5h. Reactive gases were collected with gas bags. After the reaction, the pH value was adjusted to 11-12 with NaOH / KOH, the residue after the reaction was centrifuged, washed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com