Radiation-proof fabric and production process thereof

A production process and anti-radiation technology, which is applied to layered products, metal layered products, synthetic resin layered products, etc., can solve problems such as corrosion, radiation-proof fabrics and radiation-proof effects, and achieve avoidance of twisting effect, excellent Radiation protection effect, durability improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

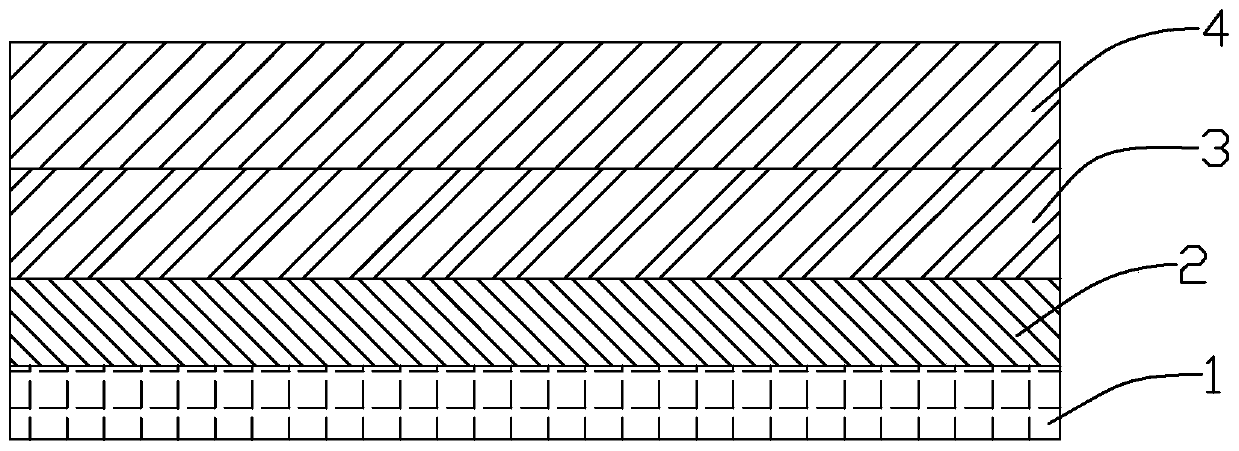

[0039]A radiation-proof fabric, comprising a base fabric layer 1, the base fabric layer 1 is woven from cotton fibers, the base fabric layer 1 is provided with a fabric layer 4, and the fabric layer 4 is made of cotton fibers and polyamide fibers blended, wherein the cotton Fiber accounts for 80%, polyamide fiber accounts for 20%; a radiation protection layer 2 is arranged between the fabric layer 4 and the base fabric layer 1;

[0040] The radiation protection layer includes the following raw materials: 30kg of nano-silver fiber, 20kg of polyphenylene sulfide fiber, 10kg of bamboo fiber, 3kg of nano-barium sulfate, 2kg of nano-titanium dioxide, 1kg of lanthanum oxide, 4kg of polyacrylonitrile and 5kg of polyurethane.

[0041] The production technology of this anti-radiation fabric comprises the following steps:

[0042] Step 1. The base fabric layer is steamed and shaped. The steamed yarn setting temperature is 80°C, and the time is controlled at 60 minutes. Then, the raw mat...

Embodiment 2

[0044] A radiation-proof fabric, comprising a base fabric layer 1, the base fabric layer 1 is woven from cotton fibers, the base fabric layer 1 is provided with a fabric layer 4, and the fabric layer 4 is made of cotton fibers and polyamide fibers blended, wherein the cotton Fiber accounts for 80%, and polyamide fiber accounts for 20%. A radiation-proof layer 2 is arranged between the fabric layer 4 and the base fabric layer 1, and a breathable layer 3 is also arranged between the fabric layer 4 and the radiation-proof layer 2. The breathable layer 3 is made of hemp fiber woven;

[0045] The radiation protection layer includes the following raw materials: 35kg of nano-silver fiber, 15kg of polyphenylene sulfide fiber, 15kg of bamboo fiber, 4kg of nano-barium sulfate, 3kg of nano-titanium dioxide, 2kg of cerium oxide, 8kg of polyacrylonitrile and 10kg of polyurethane.

[0046] The production technology of this anti-radiation fabric comprises the following steps:

[0047] Step ...

Embodiment 3

[0050] A radiation-proof fabric, comprising a base fabric layer 1, the base fabric layer 1 is woven from cotton fibers, the base fabric layer 1 is provided with a fabric layer 4, and the fabric layer 4 is made of cotton fibers and polyamide fibers blended, wherein the cotton Fiber accounts for 80%, and polyamide fiber accounts for 20%. A radiation-proof layer 2 is arranged between the fabric layer 4 and the base fabric layer 1, and a breathable layer 3 is also arranged between the fabric layer 4 and the radiation-proof layer 2. The breathable layer 3 is made of hemp fiber woven;

[0051] The radiation protection layer includes the following raw materials: 40kg of nano-silver fiber, 16kg of polyphenylene sulfide fiber, 14kg of bamboo fiber, 5kg of nano-barium sulfate, 2kg of nano-titanium dioxide, 3kg of lanthanum acrylate, 6kg of polyacrylonitrile and 9kg of polyurethane.

[0052] The production technology of this anti-radiation fabric comprises the following steps:

[0053] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com