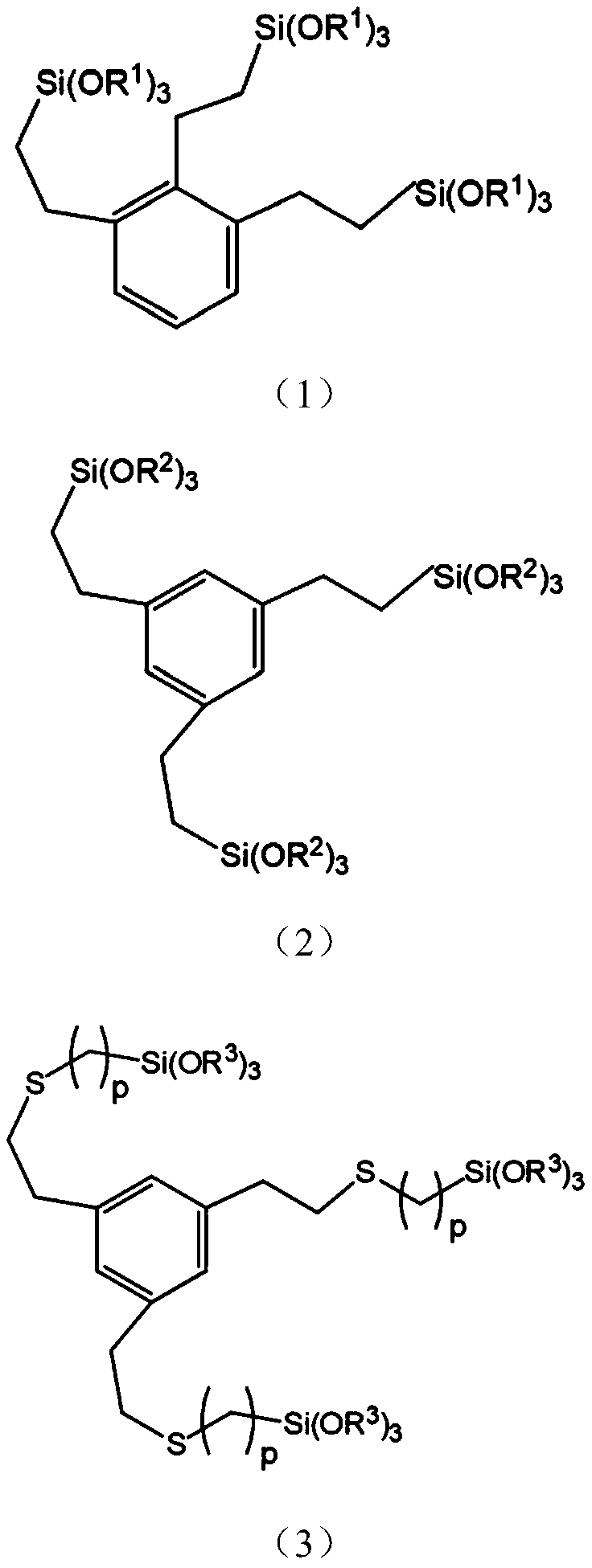

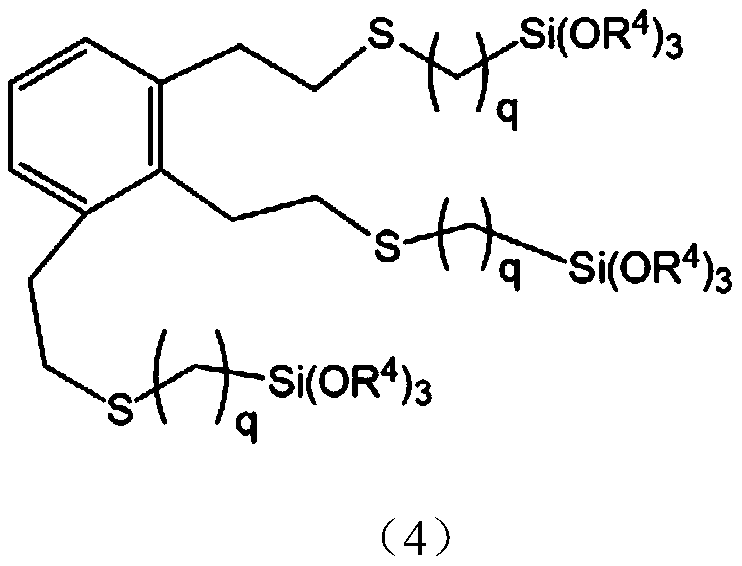

Polyalkoxy-containing silicon-based benzene compound and hybrid silicon dioxide aerogel

A technology of silica and airgel, applied in the field of airgel, can solve the problems of large specific surface area, low thermal conductivity, high cost, etc., and achieve the effect of increasing specific surface area, strengthening mechanical strength and increasing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 100g of 1,2,3-trivinylbenzene, 390g of trimethoxysilane and 1000ml of toluene into the container, raise the temperature to 90°C, add Karstedt catalyst (calculated as 10ppm according to the amount of Pt) under the protection of nitrogen, and control the reaction temperature to 115-120 °C for 4 hours. After the reaction, the solvent was distilled off and unreacted trimethoxysilane was distilled off under reduced pressure to obtain 327 g of 1,2,3-tris(trimethoxysilylethyl)benzene with a purity of 97.3% as measured by GC.

Embodiment 2

[0027] Add 100g of 1,3,5-trivinylbenzene, 630g of triethoxysilane and 2000ml of toluene into the container, raise the temperature to 90°C, add Karstedt catalyst (12ppm based on Pt amount) under the protection of nitrogen, and control the reaction temperature to 115- React at 120°C for 5 hours. After the reaction, the solvent was distilled off and unreacted triethoxysilane was distilled off under reduced pressure to obtain 407 g of 1,3,5-tris(triethoxysilylethyl)benzene with a purity of 97.8% as measured by GC.

Embodiment 3

[0029] Add 100g of 1,2,3-trivinylbenzene, 570g of 3-mercaptopropyltrimethoxysilane, 10g of benzoin butyl ether and 1000ml of absolute ethanol into the container, and irradiate with ultraviolet light with a dominant wavelength of 365nm and a light intensity of 8mW / cm for 3 minutes , removing ultraviolet light, distilling off absolute ethanol, and distilling off 3-mercaptopropyltrimethoxysilane under reduced pressure to obtain 471g of 1,2,3-tris(trimethoxysilylpropylthiaethyl)benzene, which was measured by GC The resulting purity was 96.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com