Preparation method and application of Nb2O5 nanorod

A nanorod and reactor technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of cumbersome synthesis methods, poor uniformity of nanorods, and harsh instrument requirements, and achieve shortening of ion diffusion paths and nanorods. The effect of uniform structure and fast charging and discharging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

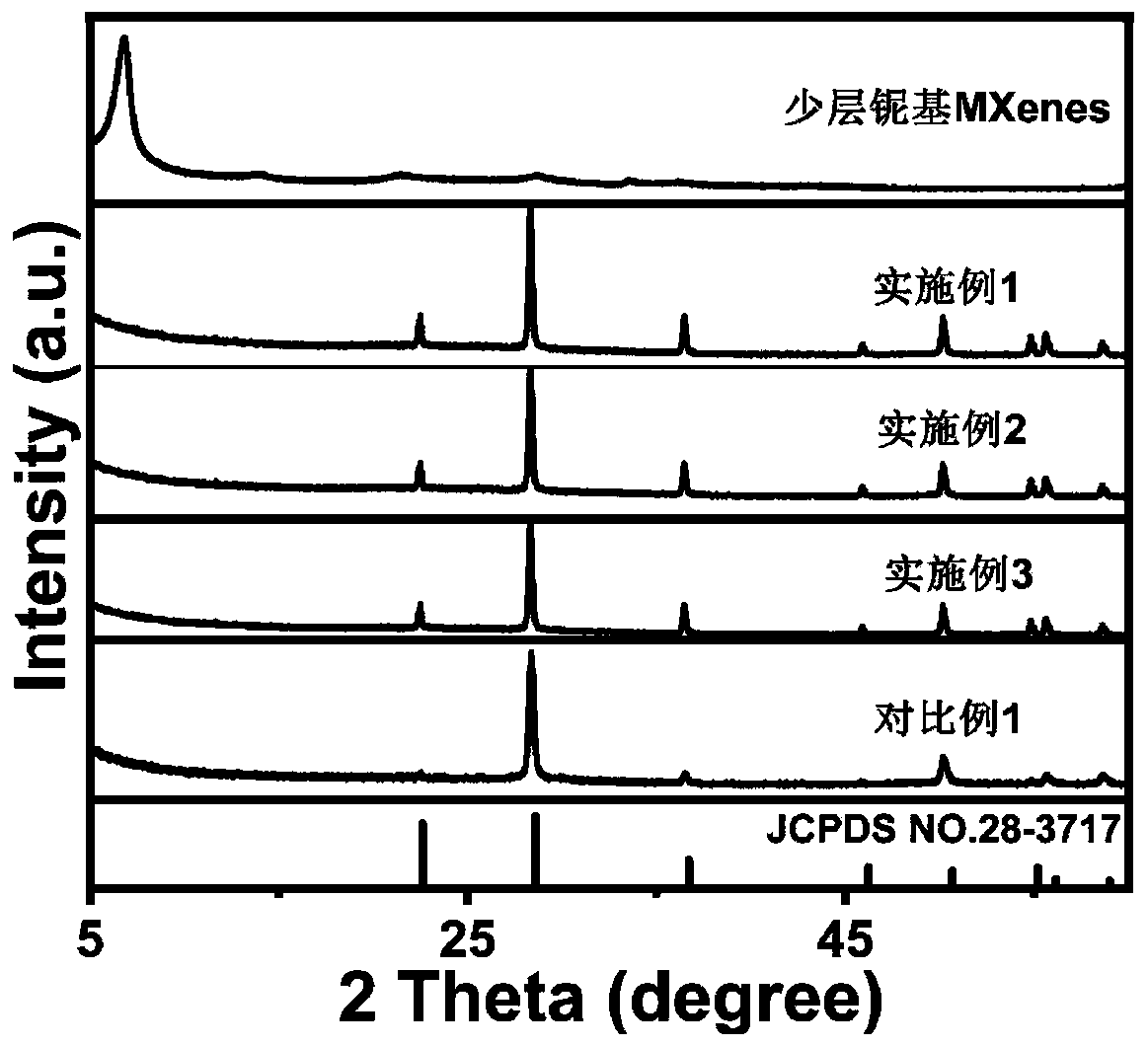

Embodiment 1

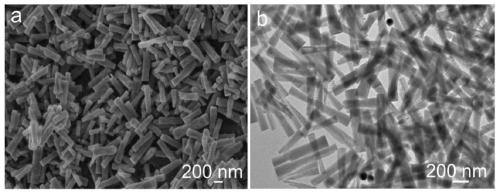

[0043] A kind of Nb provided by this embodiment 2 O 5 The preparation method of nanorod, comprises the following steps:

[0044] (1) First, 2 g Nb 2 AlC was placed in 20ml mass fraction concentration of 50% hydrofluoric acid, and etched at room temperature for 90 hours;

[0045](2) Centrifuge the etched liquid in step (1) and wash it repeatedly with deionized water and absolute ethanol until the pH is 6;

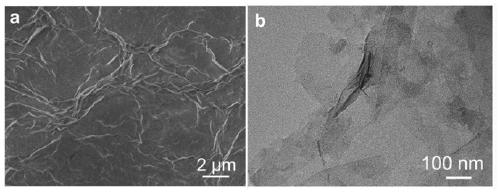

[0046] (3) Pour off the supernatant liquid of the product obtained in step (2), remove the lower layer of precipitate and place it in a vacuum drying oven to dry to obtain multi-layer MXenes;

[0047] (4) The multilayer niobium-based MXenes obtained in step (3) were placed in a tetramethylammonium hydroxide solution, and heated and stirred at 25 °C for 24 hours;

[0048] (5) Centrifuge the solution obtained in step (4) with a centrifuge, pour out the upper layer liquid obtained for the first time, add deionized water to the centrifuge tube, and then sonicate or shake vig...

Embodiment 2

[0053] A kind of Nb provided by this embodiment 2 O 5 The preparation method of nanorod, comprises the following steps:

[0054] (1) First, 2 g Nb 2 AlC was placed in 20 ml of 50% hydrofluoric acid, and etched at room temperature for 90 hours.

[0055] (2) Centrifuge the etched liquid in step (1) and wash it repeatedly with deionized water and absolute ethanol until the pH is 6;

[0056] (3) Pour off the supernatant liquid of the product obtained in step (2), remove the lower layer of precipitate and place it in a vacuum drying oven to dry to obtain multi-layer MXenes;

[0057] (4) The multi-layer niobium-based MXenes obtained in step (3) were placed in a tetramethylammonium hydroxide solution, and heated and stirred at 35 °C for 24 hours;

[0058] (5) Centrifuge the solution obtained in step (4) with a centrifuge, pour out the upper layer liquid obtained for the first time, add deionized water to the centrifuge tube, and then sonicate or shake vigorously to re-disperse th...

Embodiment 3

[0063] A kind of Nb provided by this embodiment 2 O 5 The preparation method of nanorod, comprises the following steps:

[0064] (1) First, 2 g Nb 2 AlC was placed in 20 ml mass fraction concentration of 50% hydrofluoric acid, and etched at room temperature for 90 hours;

[0065] (2) Centrifuge the etched liquid in step (1) and wash it repeatedly with deionized water and absolute ethanol until the pH is 6;

[0066] (3) Pour off the supernatant liquid of the product obtained in step (2), remove the lower layer of precipitate and place it in a vacuum drying oven to dry to obtain multi-layer MXenes;

[0067] (4) The multi-layer niobium-based MXenes obtained in step (3) were placed in a tetramethylammonium hydroxide solution, and heated and stirred at 55 °C for 6 hours;

[0068] (5) Centrifuge the solution obtained in step (4) with a centrifuge, pour out the upper layer liquid obtained for the first time, add deionized water to the centrifuge tube, and then sonicate or shake v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com