Vinylene carbonate modified binder and lithium ion battery containing same

A vinylene carbonate and binder technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low mechanical stability and low electrical conductivity of the membrane, and achieve the effect of low cost and safe use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0051] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

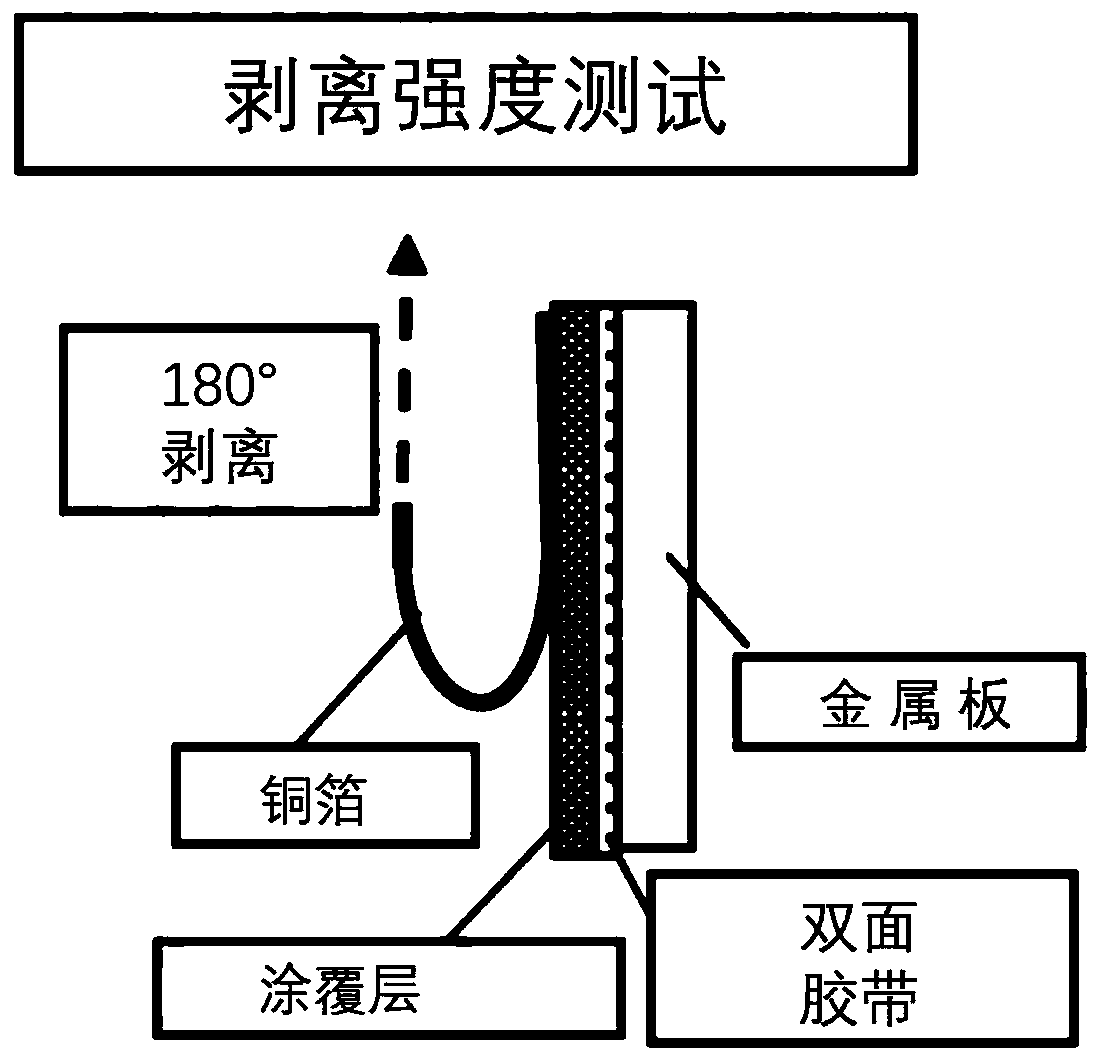

[0052] The peel force involved in the following examples is tested by the following method:

[0053] Coat the negative electrode slurry on the surface of the current collector (such as copper foil), dry and cold press to form a pole piece, cut the ...

Embodiment 1

[0058] Add 30 parts (mass parts, same below) of styrene, 70 parts of butadiene, 0.5 parts of acrylic acid, 2 parts of vinylene carbonate, 200 parts of water, 5 parts of sodium stearate, 0.5 parts of molecular weight adjustment Agent dodecyl mercaptan, nitrogen protection, stirring 300rpm, heating up to 60 ° C. After continuing to stir for 20 minutes, add 0.31 parts of potassium persulfate, keep warm at 60°C, condense, continue to stir at 300rpm, and react for 6h. Vinylene ester modified styrene-butadiene rubber emulsion binder, the average particle size of the emulsion binder is 158nm, PDI is 0.02, viscosity is 10-60mPa·s, solid content is 39-41wt%, pH=6.5 ~8.

[0059] Disperse the positive electrode active material lithium cobaltate, binder PVDF and conductive carbon black in N-methylpyrrolidone, and obtain a uniformly dispersed positive electrode slurry after stirring, wherein the solid content includes 96.8wt% lithium cobaltate, 1.3wt% PVDF and 2wt% conductive carbon blac...

Embodiment 2

[0063] Add 32 parts of styrene, 68 parts of butadiene, 3 parts of vinylene carbonate, 150 parts of water, 6 parts of sodium stearate, 0.6 part of molecular weight modifier dodecyl mercaptan in the reaction kettle, and pass into nitrogen protection, Stir at 300 rpm and heat up to 60°C. After continuing to stir for 20 minutes, add 0.3 parts of potassium persulfate, keep warm at 60°C, condense, continue to stir at 300rpm, and react for 6h. Vinyl ester modified styrene-butadiene rubber emulsion binder, the average particle size of the emulsion binder is 165nm, PDI is 0.018, viscosity is 15-50mPa·s, solid content is 38-40wt%, pH=7- 8.

[0064] The process flow of the method for making the lithium-ion battery is basically the same as in Example 1, except that the binder used is the modified styrene-butadiene rubber emulsion binder synthesized in this example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com