Dyeing process of knitted fabric, and dyeing machine

A technology for knitted fabrics and dyeing machines, applied in the field of knitted fabrics, can solve problems such as poor color fastness and uniformity of dyeing, affect the quality of knitted fabrics, and poor environmental friendliness, so as to ensure uniformity of dyeing, improve color fastness, and improve texture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A kind of dyeing process of knitted fabric

[0041] Include the following steps:

[0042] Step 1, pretreatment: put the knitted fabric into a pretreatment solution with a temperature of 65° C., soak it for 20 minutes, then dry it, repeat the dipping once, and dry it again to obtain the pretreated knitted fabric; wherein, the pretreated knitted fabric The moisture content is 5%; the pretreatment solution is composed of citric acid, sodium octyl sulfosuccinate, dopamine, hydrogen peroxide and deionized water with a mass ratio of 1:3.5:0.5:0.05:60;

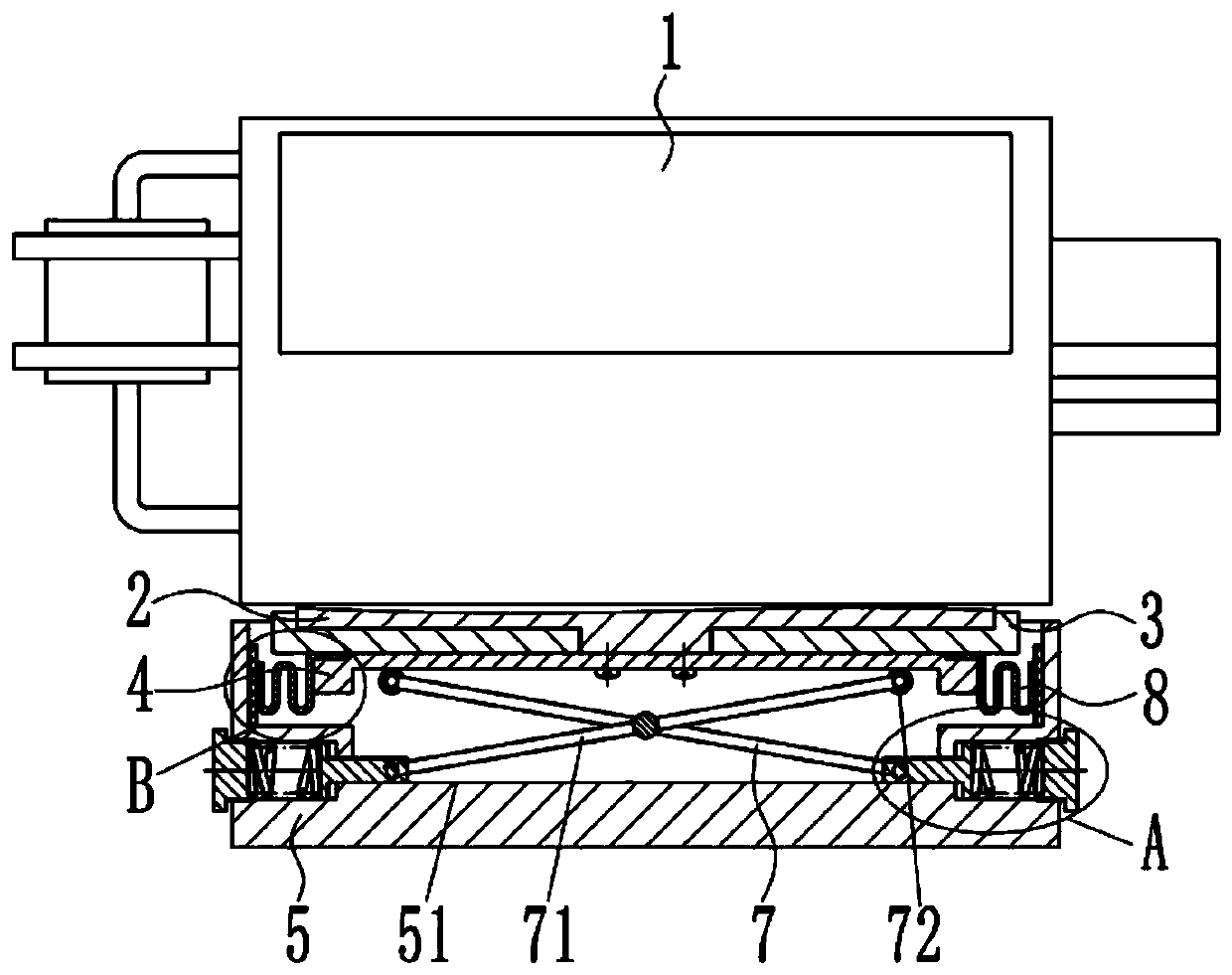

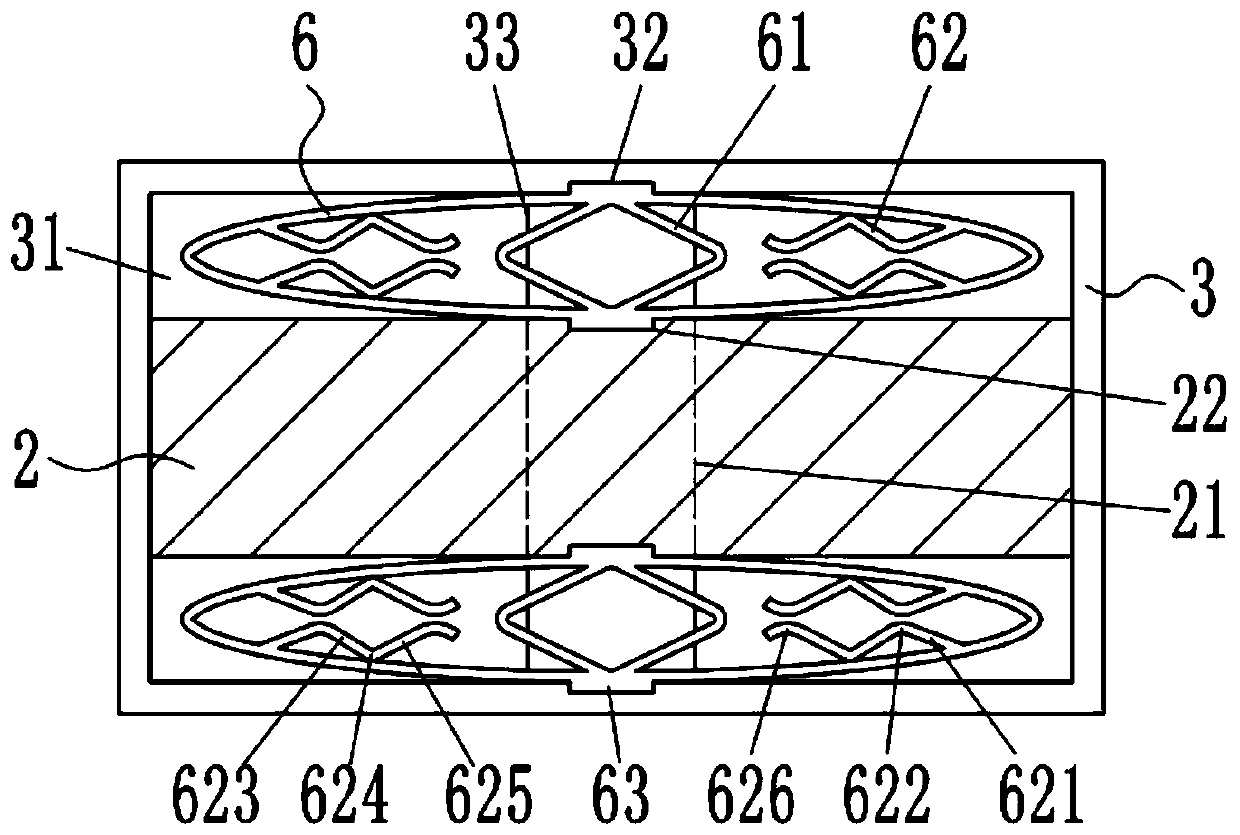

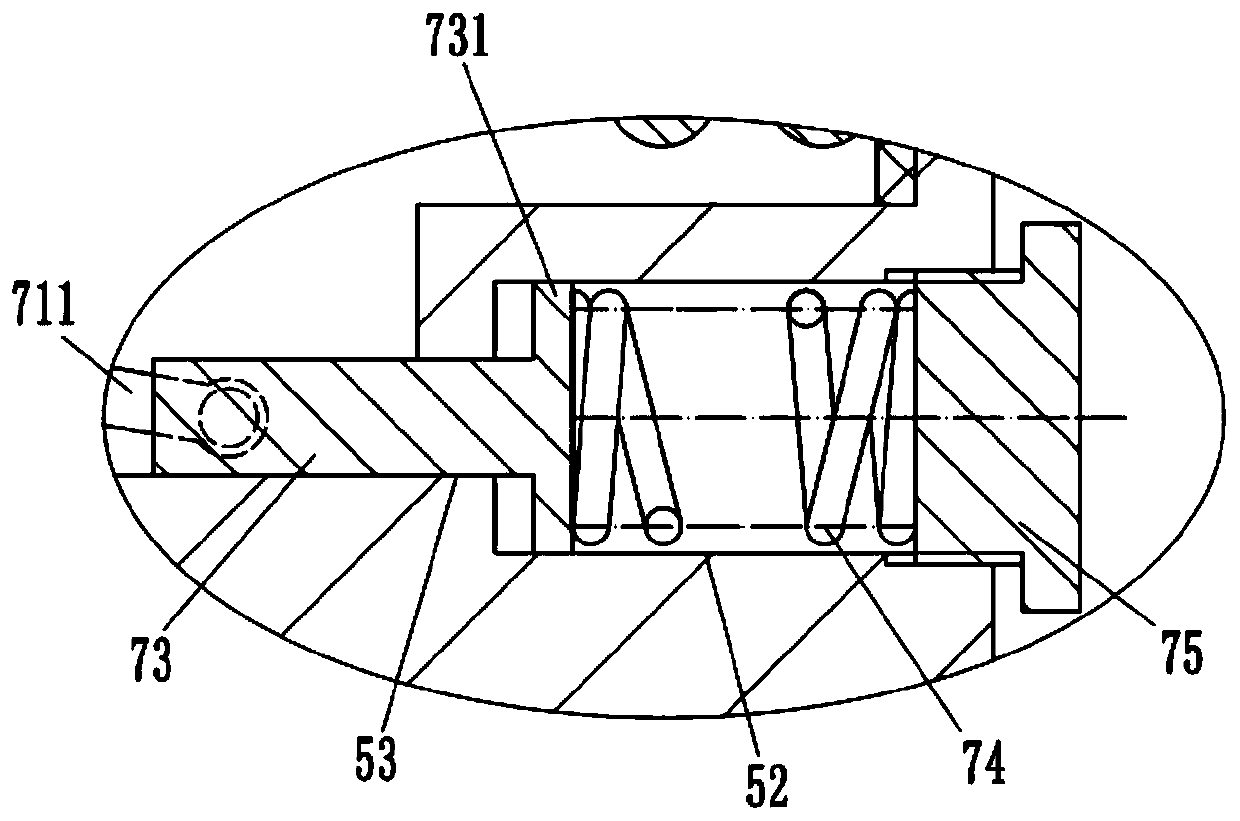

[0043] Step II, dyeing: the pretreated knitted fabric obtained in step I is dyed with plant dyeing solution for 80 minutes in a dyeing machine to obtain a dyed knitted fabric; wherein, during the dyeing process, the dyeing bath ratio is 1:8.5, and the dyeing temperature is 38°C ;

[0044] Step III, drying: the dyed knitted fabric obtained in step II is dried at a temperature of 95°C, washed twice with warm water, and then dr...

Embodiment 2

[0053] A kind of dyeing process of knitted fabric

[0054] Include the following steps:

[0055] Step 1, pretreatment: put the knitted fabric into a pretreatment solution with a temperature of 75° C., soak it for 30 minutes, then dry it, repeat the dipping once, and dry it again to obtain the pretreated knitted fabric; wherein, the pretreated knitted fabric The moisture content is 8%; the pretreatment solution is composed of citric acid, sodium octyl sulfosuccinate, dopamine, hydrogen peroxide and deionized water with a mass ratio of 1:3.5:0.5:0.05:70;

[0056] Step II, dyeing: the pretreated knitted fabric obtained in step I is dyed with plant dyeing solution for 100 minutes in a dyeing machine to obtain a dyed knitted fabric; wherein, during the dyeing process, the dyeing bath ratio is 1:9.5, and the dyeing temperature is 42°C ;

[0057] Step III, drying: the dyed knitted fabric obtained in step II is dried at a temperature of 115° C., washed with warm water for 3 times, a...

Embodiment 3

[0061] A kind of dyeing process of knitted fabric

[0062] Include the following steps:

[0063] Step 1, pretreatment: put the knitted fabric into a pretreatment solution with a temperature of 68° C., soak it for 22 minutes, then dry it, repeat the dipping once, and dry it again to obtain the pretreated knitted fabric; wherein, the pretreated knitted fabric The moisture content is 6%; the pretreatment solution is composed of citric acid, sodium octyl sulfosuccinate, dopamine, hydrogen peroxide and deionized water with a mass ratio of 1:3.5:0.5:0.05:62;

[0064] Step II, dyeing: the pretreated knitted fabric obtained in step I is dyed with plant dyeing solution for 85 minutes in a dyeing machine to obtain a dyed knitted fabric; wherein, during the dyeing process, the dyeing bath ratio is 1:8.8, and the dyeing temperature is 39°C ;

[0065] Step III, drying: the dyed knitted fabric obtained in step II is dried at a temperature of 90°C, washed with warm water for 3 times, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com