Anhydrous ionic liquid and application thereof in flue gas desulfurization

A technology of water ions and ionic liquids, which is applied in the field of anhydrous ionic liquids, can solve problems such as equipment corrosion, and achieve the effects of easy transportation, simple preparation methods, and good industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Preparation of ionic liquids : When m=0, and n=0, mix 2-amino-2-methyl-1-propanol (AMP) with benzoic acid (BA) in the same amount at 20°C, stir for 30min, and generate Amino acid salt [AMP] + [BA] - . The obtained amino acid salt is added into benzyl alcohol to prepare anhydrous ionic liquid. Wherein the amount of 2-amino-2-methyl-1-propanol (AMP) in the ionic liquid is 20wt%, and the reaction formula of the amino acid salt is

[0062]

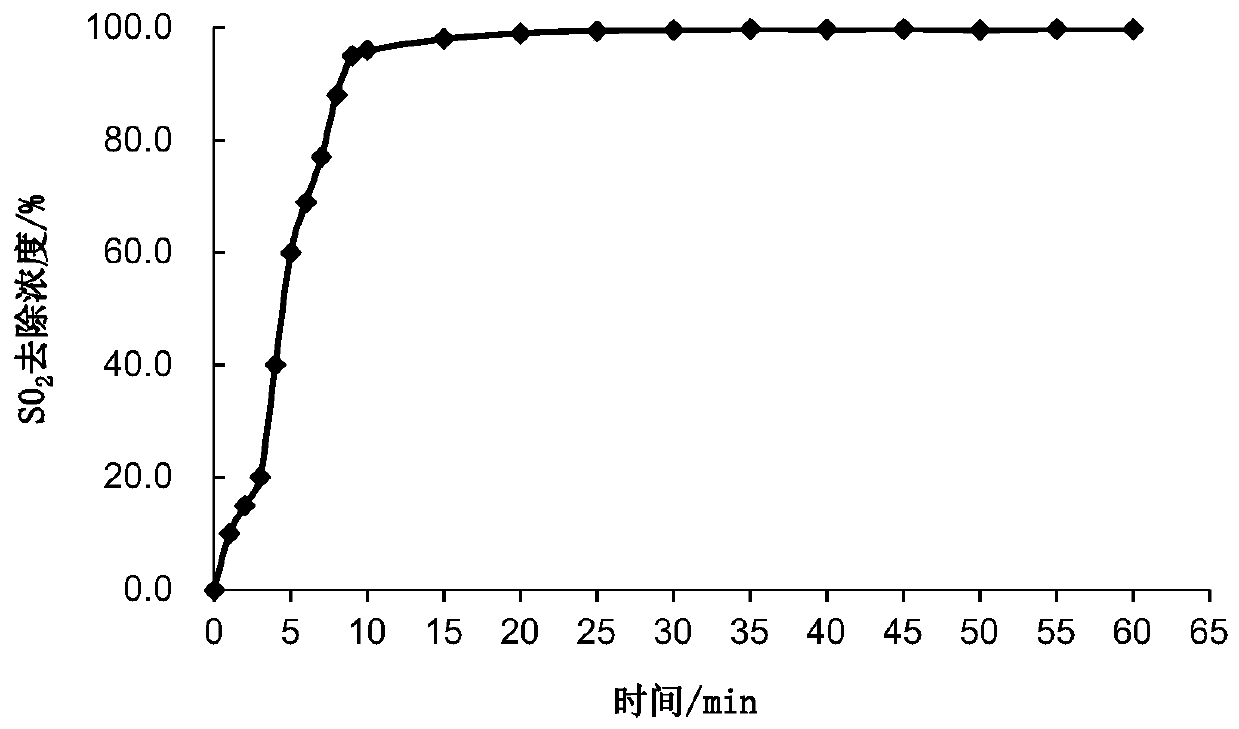

[0063] Analysis of Ionic Liquids Before and After Absorption Using TOC : Absorption of SO in simulated flue gas using the above-mentioned ionic liquid 2 ,From image 3 It can be seen that when using ionic liquid to absorb for about 10min, the SO in the simulated flue gas 2 That is, more than 99.79% is absorbed; when the ionic liquid is in contact with the simulated flue gas for 60 minutes, the SO in the simulated flue gas 2 down to 0.0021%. From Figure 4 It can be seen that CO in ionic liquid 2 The initial concentration...

Embodiment 2

[0065] Preparation of ionic liquids : When m=1, and n=1, mix 2-amino-2-methyl-1-butanol (AMB) and phenylacetic acid (PEA) in the same amount at 30°C and stir for 30min to generate Amino acid salt [AMB] + [PEA] - . The obtained amino acid salt is added into phenethyl alcohol to prepare anhydrous ion liquid. Wherein the amount of 2-amino-2-methyl-1-butanol in the ionic liquid is 20wt%, and the reaction formula of the amino acid salt is

[0066]

[0067] Analysis of Ionic Liquids Before and After Absorption Using TOC : Absorption of SO in simulated flue gas using the above-mentioned ionic liquid 2 ,From Figure 5 It can be seen that when using ionic liquid to absorb for about 10min, the SO in the simulated flue gas 2 That is, more than 99.73% is absorbed; when the ionic liquid is in contact with the simulated flue gas for 60 minutes, the SO in the simulated flue gas 2 down to 0.0027%. From Figure 6 It can be seen that CO in ionic liquid 2 The initial concentratio...

Embodiment 3

[0069] Preparation of ionic liquids : when m=2, and n=2, mix 2-amino-2-methyl-1-pentanol (AMPE) and phenylpropionic acid (PBA) in an equal amount at 40°C, stir for 25min, Formation of amino acid salts [AMPE] + [PBA] - . The obtained amino acid salt is added into phenethyl alcohol to prepare anhydrous ion liquid. Wherein the amount of 2-amino-2-methyl-1-pentanol in the ionic liquid is 20wt%, and the reaction formula of the amino acid salt is

[0070]

[0071] Analysis of Ionic Liquids Before and After Absorption Using TOC : Absorption of SO in simulated flue gas using the above-mentioned ionic liquid 2 ,From Figure 7 It can be seen that when using ionic liquid to absorb for about 20min, the SO in the simulated flue gas 2 That is, more than 99.7% is absorbed; when the ionic liquid is in contact with the simulated flue gas for 60 minutes, the SO in the simulated flue gas 2 down to 0.003%. From Figure 8It can be seen that CO in ionic liquid 2 The initial concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com