Preparation method of NiMo alloy catalyst supported by TiO2 nanotube array

A technology of nanotube arrays and alloy catalysts, which is applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., and can solve problems such as expensive prices and scarce crustal reserves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of TiO 2 A method for preparing a NiMo alloy catalyst supported by a nanotube array, the steps comprising:

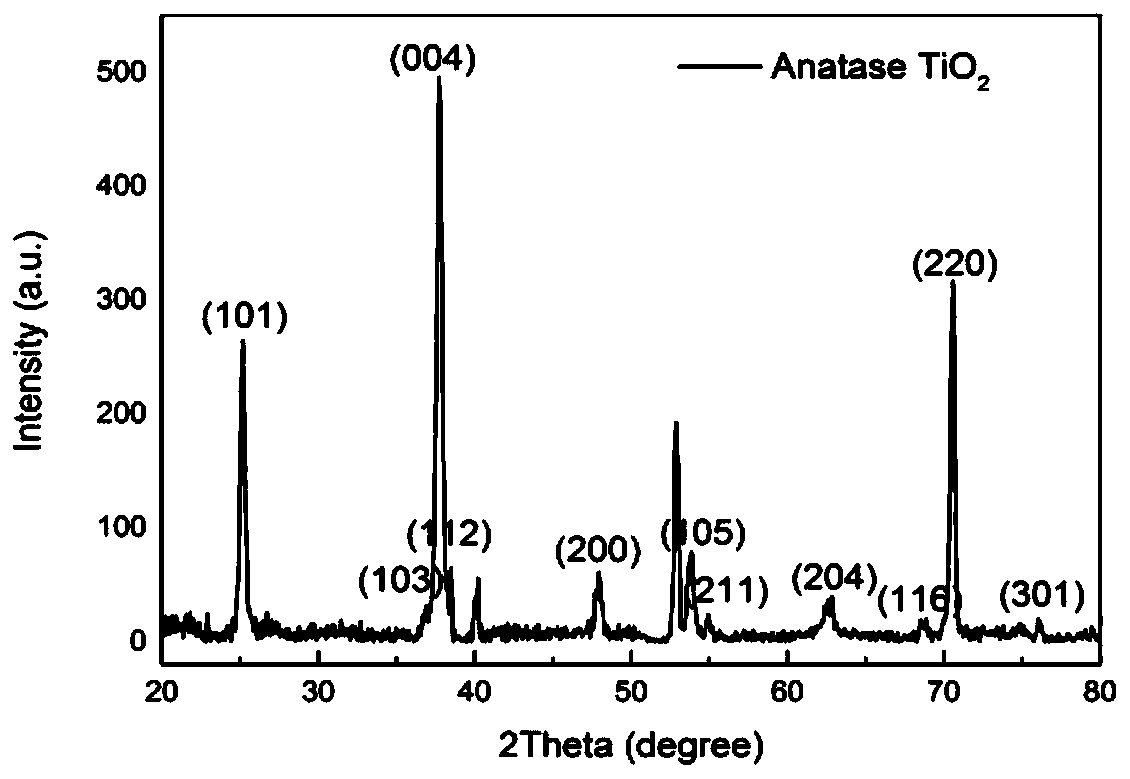

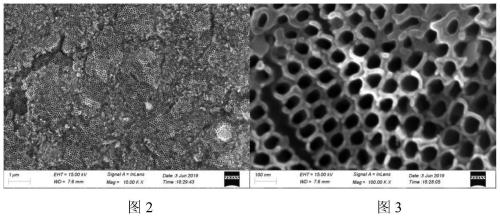

[0034] Step 1. TiO 2 Fabrication of nanotube arrays

[0035] (1) Titanium substrate pretreatment

[0036] Cut the titanium foil into 1×3cm 2 Size, ultrasonic cleaning in sequence of 10% hydrochloric acid solution, deionized water, acetone and absolute ethanol for 10 minutes;

[0037] (2) Chemical polishing of titanium substrate

[0038] The cleaned titanium substrate is placed in a chemical polishing solution for chemical polishing, and the composition volume ratio of the polishing solution is: HF:HNO 3 :H 2 O=1:4:5, the polished titanium substrate has a metallic luster;

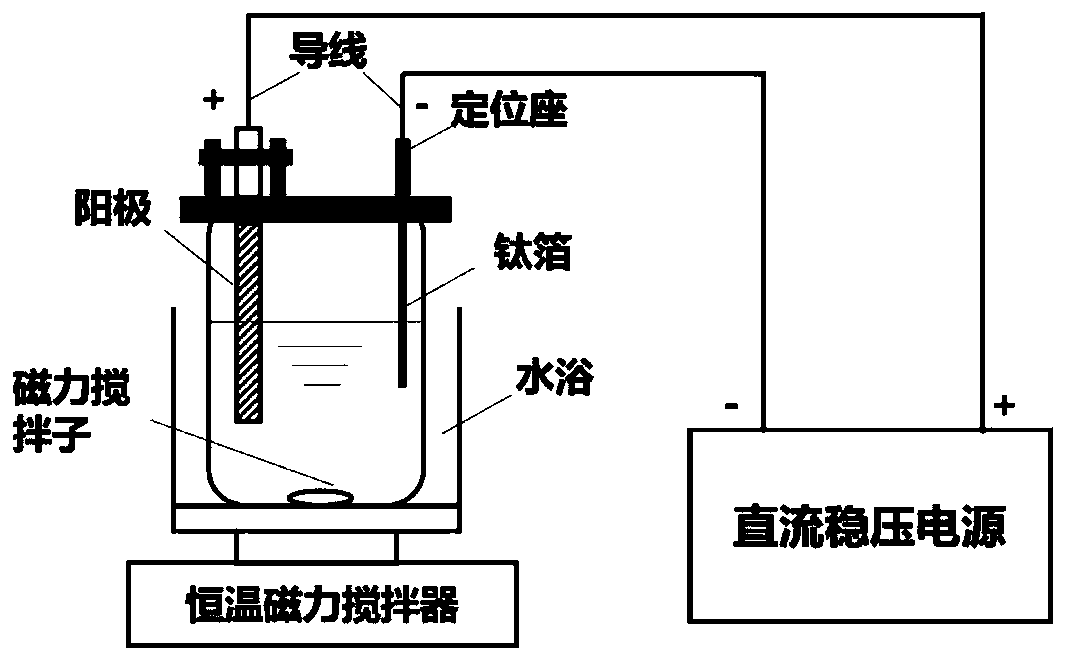

[0039] (3) Anodizing of titanium substrate

[0040] The polished titanium substrate is used as the anode, and the graphite rod is used as the cathode. A two-electrode system is used for anodic oxidation in the electrolyte. The configuration method of the electrolyte is: take 0.27...

Embodiment 2

[0053] A kind of TiO 2 A method for preparing a NiMo alloy catalyst supported by a nanotube array, the steps comprising:

[0054] Step 1. TiO 2 Fabrication of nanotube arrays

[0055] (1) Titanium substrate pretreatment

[0056] Cut the titanium foil into 1×3cm 2 Size, ultrasonic cleaning in sequence of 10% hydrochloric acid solution, deionized water, acetone and absolute ethanol for 10 minutes;

[0057] (2) Chemical polishing of titanium substrate

[0058] The cleaned titanium substrate is placed in a chemical polishing solution for chemical polishing, and the composition volume ratio of the polishing solution is: HF:HNO 3 :H 2 O=1:4:5, the polished titanium substrate has a metallic luster;

[0059] (3) Anodizing of titanium substrate

[0060] The polished titanium substrate is used as the anode, and the graphite rod is used as the cathode. A two-electrode system is used for anodic oxidation in the electrolyte. The configuration method of the electrolyte is: take 0.27...

Embodiment 3

[0073] A kind of TiO 2 A method for preparing a NiMo alloy catalyst supported by a nanotube array, the steps comprising:

[0074] Step 1. TiO 2 Fabrication of nanotube arrays

[0075] (1) Titanium substrate pretreatment

[0076] Cut the titanium foil into 1×3cm 2 Size, ultrasonic cleaning in sequence of 10% hydrochloric acid solution, deionized water, acetone and absolute ethanol for 10 minutes;

[0077] (2) Chemical polishing of titanium substrate

[0078] The cleaned titanium substrate is placed in a chemical polishing solution for chemical polishing, and the composition volume ratio of the polishing solution is: HF:HNO 3 :H 2 O=1:4:5, the polished titanium substrate has a metallic luster;

[0079] (3) Anodizing of titanium substrate

[0080] The polished titanium substrate is used as the anode, and the graphite rod is used as the cathode. A two-electrode system is used for anodic oxidation in the electrolyte. The configuration method of the electrolyte is: take 0.27...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com