Method for removing tetracycline hydrochloride in water by catalytically activating sodium persulfate under visible light by using CeO2 composite BiOI material

A technology of tetracycline hydrochloride and sodium persulfate, applied in the environmental field, can solve problems such as high cost, poor efficiency, and difficult antibiotic degradation, and achieve the effects of high use efficiency, reduced energy cost, and short removal time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

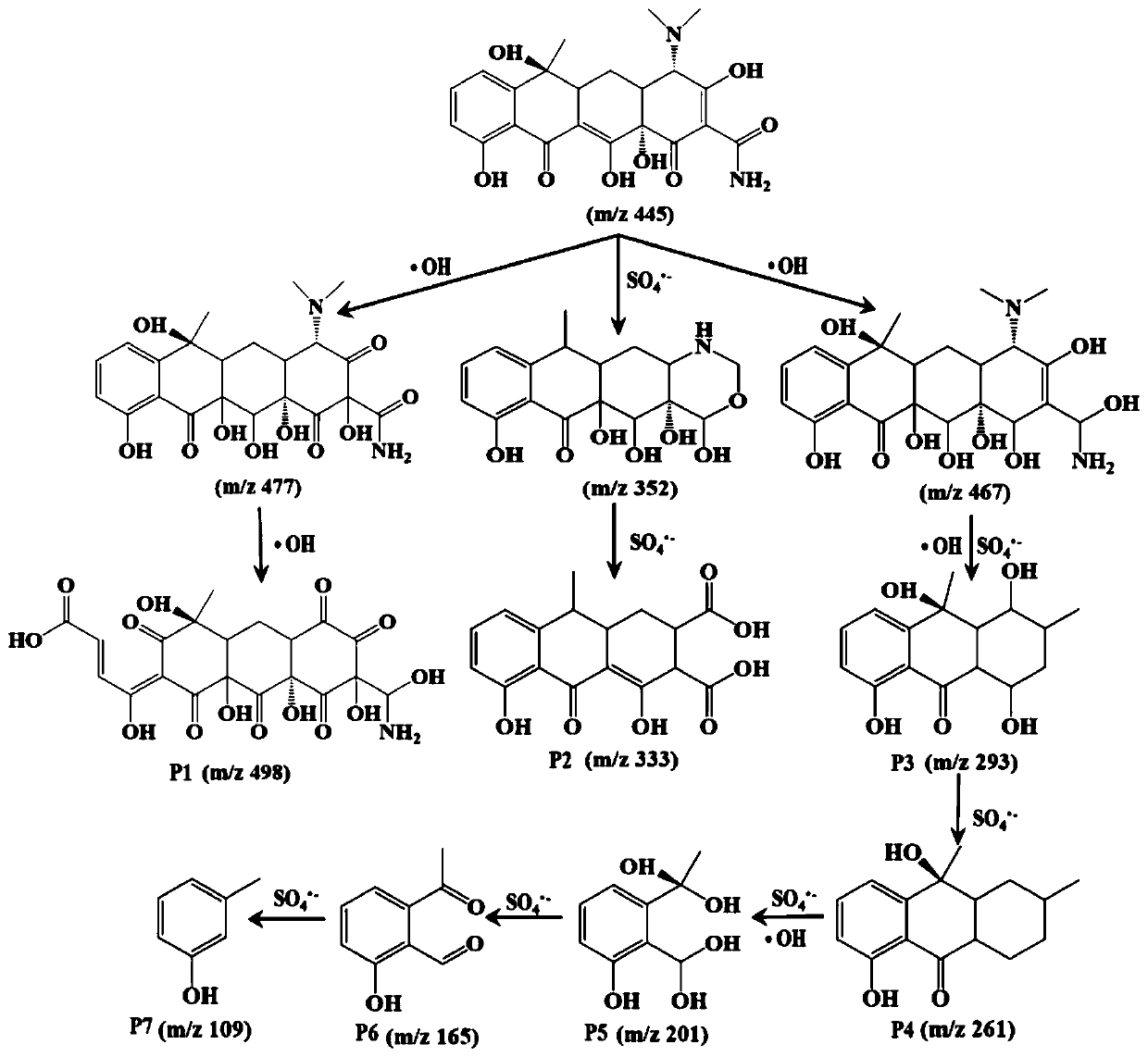

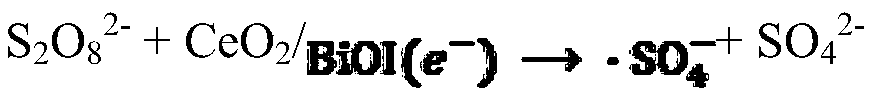

[0039] The present invention utilizes CeO Composite BiOI material Catalytic activation sodium persulfate removes the method for tetracycline hydrochloride in water under visible light, wherein the degradation process of tetracycline hydrochloride is as follows figure 1 As shown, the specific implementation includes the following steps:

[0040] (1) 0.3mmol of CeO 2 The nano powder was ultrasonically dispersed at a frequency of 20khz for 30min in ultrapure water with a volume of 40mL to form a uniform solution A; 3.0mmol of Bi(NO 3 )3·5H 2 O was uniformly magnetically stirred at 160r / min for 45min to dissolve in 30Ml of ethylene glycol solution to form a uniform solution B; 3.0mmol of KI was dissolved in 30mL of ultrapure water, and ultrasonicated at 20khz for 30min to form a uniform solution C;

[0041] (2) Solution B is added dropwise to solution A under magnetic stirring conditions to form mixed solution D, and solution D is magnetically stirred and mixed for a period of ...

Embodiment 2

[0052] The comparative test of using visible light to remove tetracycline hydrochloride in water is specifically completed according to the following steps:

[0053] 100 mL of tetracycline hydrochloride solution with a concentration of 100 mg / L was magnetically stirred at a speed of 150 r / min under visible light irradiation, and reacted for 30 min to obtain water from which residual antibiotics were removed;

[0054] In embodiment 2, the visible light adopts a xenon lamp light source, and uses a visible light filter to filter out other illuminations other than visible light, and the visible light power is 500W

[0055] In Example 2, the removal rate of antibiotics in pretreated water using sodium persulfate was 0%.

Embodiment 3

[0057] Use sodium persulfate to remove the comparative test of tetracycline hydrochloride in water, specifically complete according to the following steps:

[0058] Add 0.1 g of sodium persulfate to 100 mL of tetracycline hydrochloride solution with a concentration of 100 mg / L, and stir magnetically in the dark at a speed of 150 r / min, and react for 30 min to obtain water that removes residual antibiotics in the water;

[0059] In Example 3, sodium persulfate was used to remove antibiotics in pretreated water with a removal rate of 5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com