Preparation method of beta-nicotinamide mononucleotide and purification method

A purification method and single nucleotide technology are applied in the field of preparation of β-nicotinamide mononucleotide, which can solve the problems of many by-products, numerous steps, low yield and the like, and achieve cost savings, improved selectivity, and improved operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

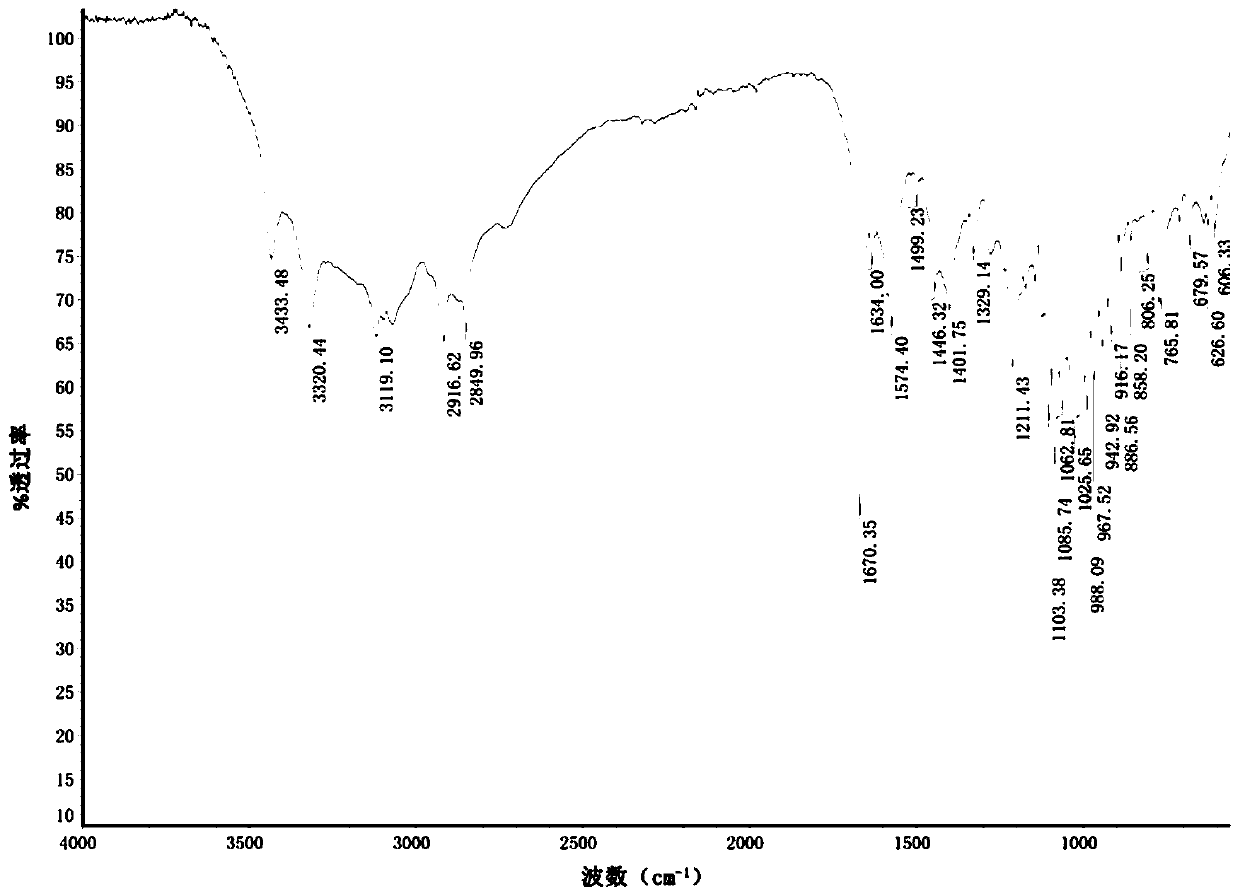

Image

Examples

preparation example Construction

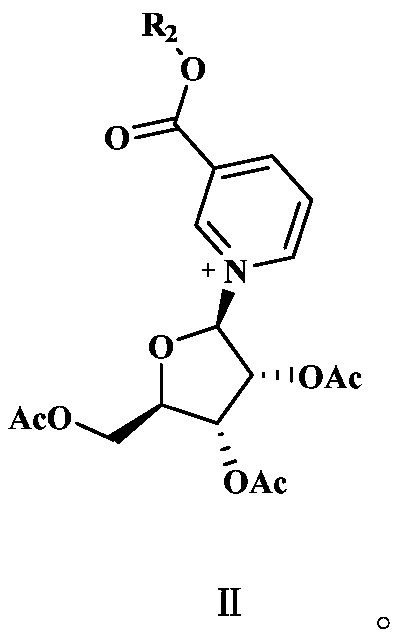

[0046] The preparation method of the raw material furanose substrate intermediate material comprises the following steps:

[0047] Step (1) Add 800 mL of dichloromethane and 80 g of tetraacetyl ribose into a 2L glass reactor, and start stirring. Turn on the circulating water in the jacket, and when the internal temperature reaches 12°C, add 5.6 g of trimethylsilyl trifluoromethanesulfonate with a constant pressure dropping funnel, and drop it in 20 minutes. 6g of nicotinyl ethyl ester was added, the temperature of the circulating water was raised, and when the temperature reached 49° C., the reaction was kept for 4 hours. After using HPLC to monitor that the remaining ethyl nicotinate was less than 5%, the solvent was evaporated to dryness under a vacuum of -0.09MPa.

[0048] Step (2) Pour 1L of methanol pre-cooled to 10°C into the system, start stirring to dissolve the material, turn on the circulating water of the reactor, and after the internal temperature reaches -5°C, pass...

Embodiment 1

[0051] Step 1: adopt the preparation method of the above-mentioned raw material furanose substrate intermediate material to obtain the raw material furanose substrate intermediate material; in the step (2) of the preparation method of the raw material furanose substrate intermediate material, the solvent removal process is carried out in a rotary evaporator Carry out solvent removal treatment at a vacuum of -0.09MPa and a temperature of 10°C, and recover the solvent.

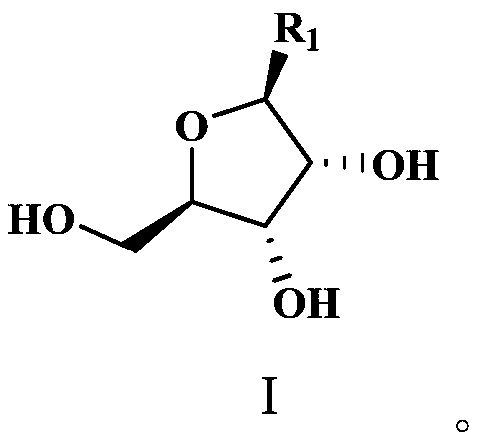

[0052] Step 2: Transfer the furanose substrate intermediate material into a 2L flask, pour into 380g of water and 220g of dichloromethane, mix under stirring conditions, the mixing time is 12min, and transfer to a 2L separatory funnel after mixing , standing for stratification, and collecting the oil phase containing the compound shown in formula I; the mass ratio of water to the raw material furanose substrate intermediate material is 8:1; the mass ratio of dichloromethane to the raw material furanose substrate ...

Embodiment 2

[0056] Step 1: adopt the preparation method of the above-mentioned raw material furanose substrate intermediate material to obtain the raw material furanose substrate intermediate material; in the step (2) of the preparation method of the raw material furanose substrate intermediate material, the solvent removal process is carried out in a rotary evaporator Carry out solvent removal treatment at a vacuum of -0.085MPa and a temperature of 15°C, and recover the solvent.

[0057] Step 2: Transfer the raw furanose substrate intermediate material into a 1L flask, pour into 140g of water and 100g of ethyl acetate, mix under stirring, the mixing time is 10min, and transfer to a 1L separatory funnel after mixing , standing and stratifying, and collecting the oil phase containing the compound shown in formula I; the mass ratio of water to the raw material furanose substrate intermediate material is 10:1; the mass ratio of dichloromethane to the raw material furanose substrate intermedia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com