Organic-inorganic-ionic liquid composite solid electrolyte, preparation method and application thereof

A solid electrolyte, ionic liquid technology, applied in solid electrolytes, hybrid capacitor electrolytes, non-aqueous electrolytes, etc., can solve the problems of low ionic conductivity of polymer electrolytes, poor mechanical properties of polymer electrolyte membranes, and uneven dispersion of inorganic particles. , to achieve the effect of improving electrochemical performance, conducive to transmission, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] One aspect of the embodiments of the present invention provides a method for preparing an organic-inorganic-ionic liquid composite solid electrolyte, which includes:

[0039] Provide a uniform mixed reaction system comprising polymer monomers, inorganic nanoparticles, lithium salts, ionic liquids and initiators, wherein the polymer monomers, inorganic nanoparticles and ionic liquids all have reactive vinyl functional groups;

[0040] Lighting or heating the uniformly mixed reaction system allows polymer monomers, inorganic nanoparticles and ionic liquids in the uniformly mixed reaction system to undergo in-situ polymerization to obtain an organic-inorganic-ionic liquid composite solid electrolyte.

[0041] In some preferred embodiments, the preparation method specifically includes:

[0042] (1) uniformly mixing the lithium salt with the ionic liquid to obtain a lithium salt solution;

[0043] (2) uniformly mixing polymer monomers, inorganic nanoparticles and a solvent ...

Embodiment 1

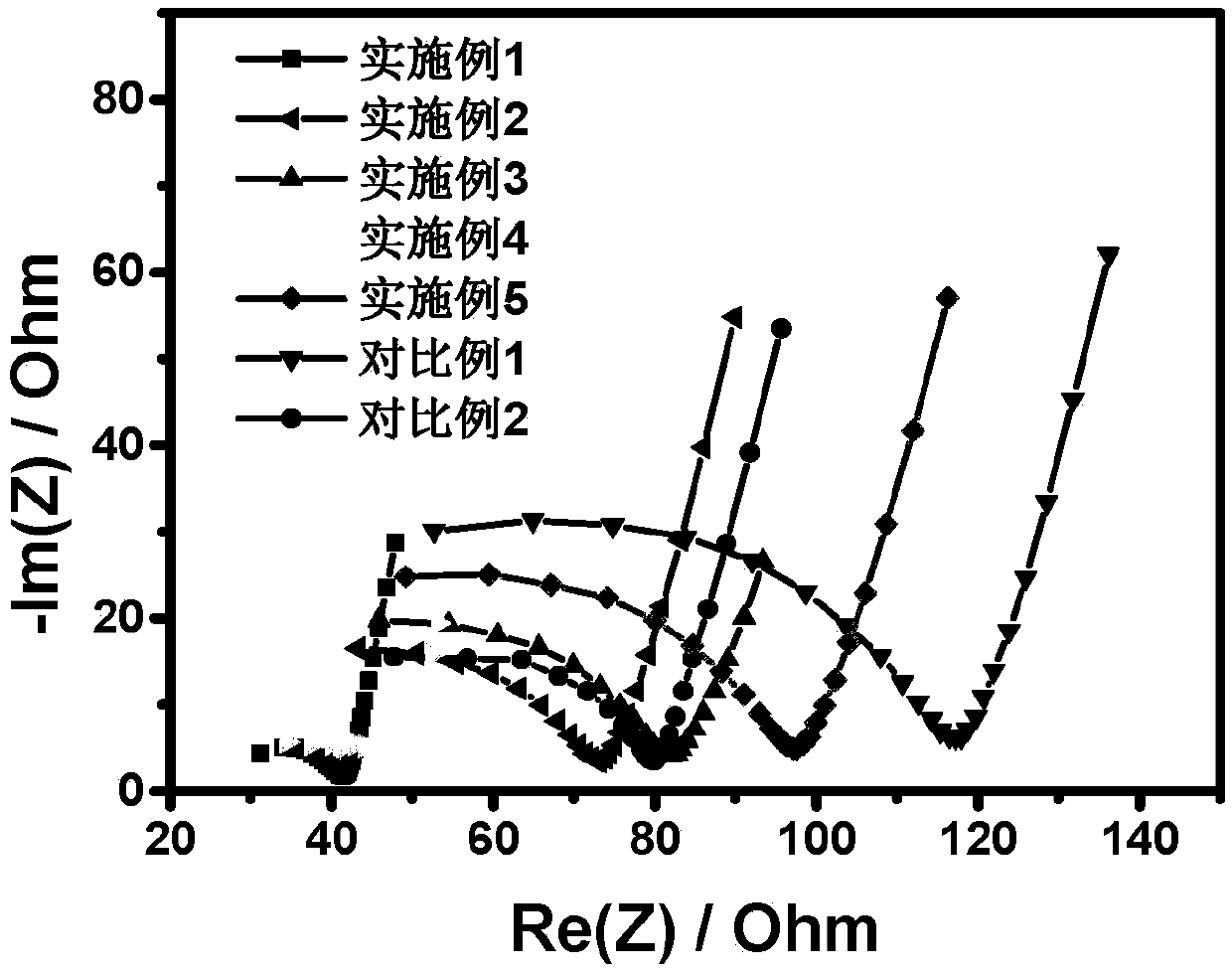

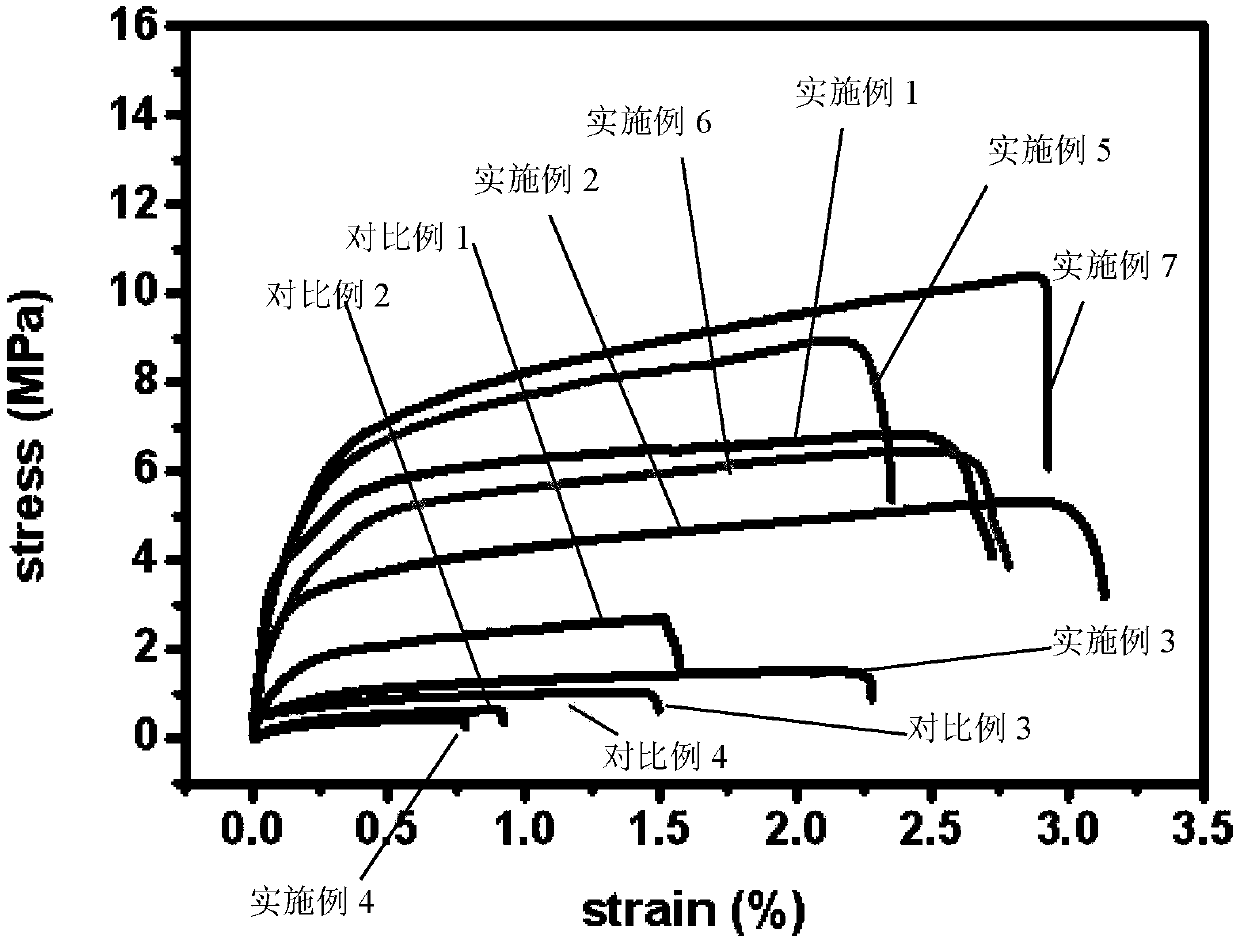

[0078] LiFSI: 0.4g, ionic liquid: 1-vinyl-3-ethylimidazolium hexafluorophosphate: 1.6g, stir while heating at 60°C to obtain lithium salt solution and cool to room temperature, polyethylene glycol diacrylate- 400: 0.5g, Tetramethyltetravinylcyclotetrasiloxane: 0.1g, the two were dissolved in 0.5mL of acetone, stirred evenly and added to the lithium salt solution, and the photoinitiator 2-hydroxyl-2 -Methyl-1-phenyl-1-propanone (HMPP) 5 μL, magnetically stirred evenly, scraped a 300 μm film on a glass plate, and irradiated with a UV lamp for 5 minutes to obtain an electrolyte membrane with a thickness of about 200 μm and an ionic conductivity of 2.5 ×10 -4 S cm -1 , The mechanical strength is 6.1MPa.

Embodiment 2

[0080] LiFSI: 0.4g, ionic liquid: 1-vinyl-3-ethylimidazolium hexafluorophosphate: 2.8g, stir while heating at 60°C to obtain lithium salt solution and cool to room temperature, polyethylene glycol diacrylate- 400: 0.4g, tetramethyltetravinylcyclotetrasiloxane: 0.4g, the two were dissolved in 0.5mL of acetone, stirred evenly and added to the lithium salt solution, and the photoinitiator 2-hydroxyl-2 -Methyl-1-phenyl-1-propanone (HMPP) 4 μL, magnetically stirred evenly, scrape-coated a 300 μm film on a glass plate, and irradiated with a UV lamp for 5 minutes to obtain an electrolyte membrane with a thickness of about 200 μm and an ionic conductivity of 1.4 ×10 -4 S cm -1 , The mechanical strength is 4.9MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com