PVC cable material for 5G photoelectric composite cable

A photoelectric hybrid cable and cable material technology, which is applied in the field of cables, can solve problems such as easy reunion, product low temperature resistance performance decline, and product softness, etc., to achieve the effects of reducing agglomeration, improving low temperature resistance performance, and reducing signal attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

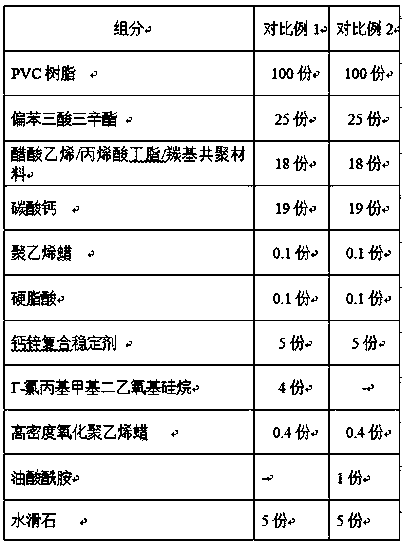

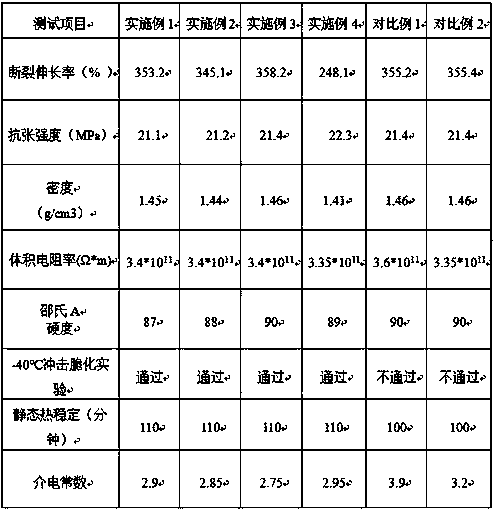

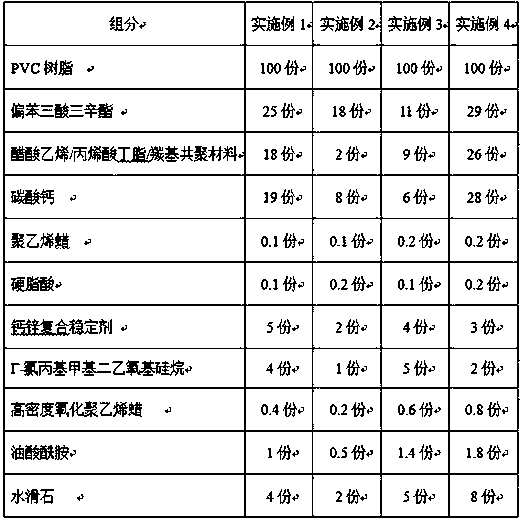

[0025] Embodiments 1 to 4: A PVC cable material for 5G photoelectric hybrid cables, comprising the following components in parts by weight:

[0026] Table 1

[0027]

Embodiment 1

[0028] The polymerization degree of PVC resin is equal to 1300 among the embodiment 1, and calcium carbonate mesh number is equal to 2500 mesh. The degree of polymerization of PVC resin in embodiment 2 is equal to 1300, and the calcium carbonate mesh number is equal to 2550 mesh. The degree of polymerization of PVC resin in embodiment 3 is equal to 1400, and the calcium carbonate mesh number is equal to 2600 mesh. The degree of polymerization of PVC resin in embodiment 4 is equal to 1400, and the calcium carbonate mesh number is equal to 2500 mesh.

[0029] The preparation method of the above-mentioned PVC cable material for 5G photoelectric hybrid cable is as follows:

[0030] S1: Weigh 1~5 parts of Γ-chloropropylmethyldiethoxysilane and 1~30 parts of vinyl acetate / butyl acrylate / carbonyl copolymer material, premix the above high-density oxidized polyethylene with a high-mixer Wax and Γ-chloropropylmethyldiethoxysilane are coated on the surface of vinyl acetate / butyl acryla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com