Horizontal push-flow continuous dry fermentation equipment and method

A dry fermentation device and fermentation device technology, applied in biochemical cleaning devices, biochemical equipment and methods, enzymology/microbiology devices, etc., can solve the problems of short service life of feeding and discharging equipment, unbalanced microbial habitat environment, and poor material fluidity and other problems, to achieve the effects of quick replacement or maintenance, strong anti-risk ability, and stable system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

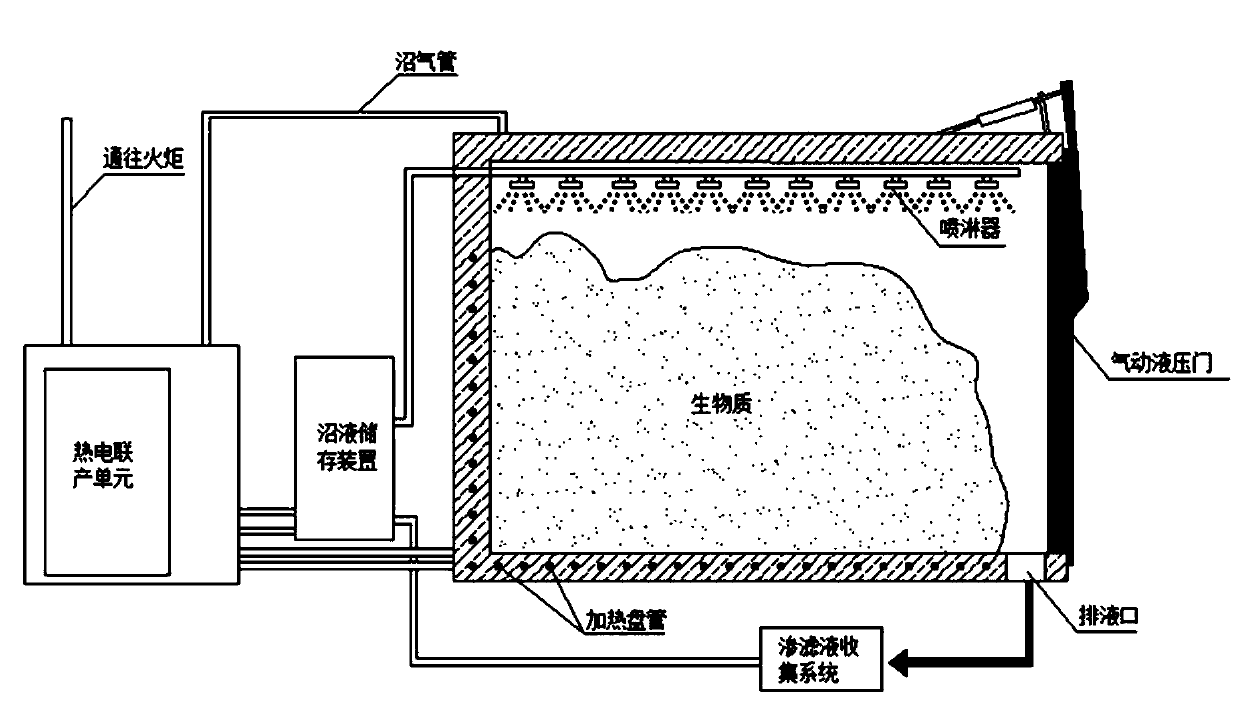

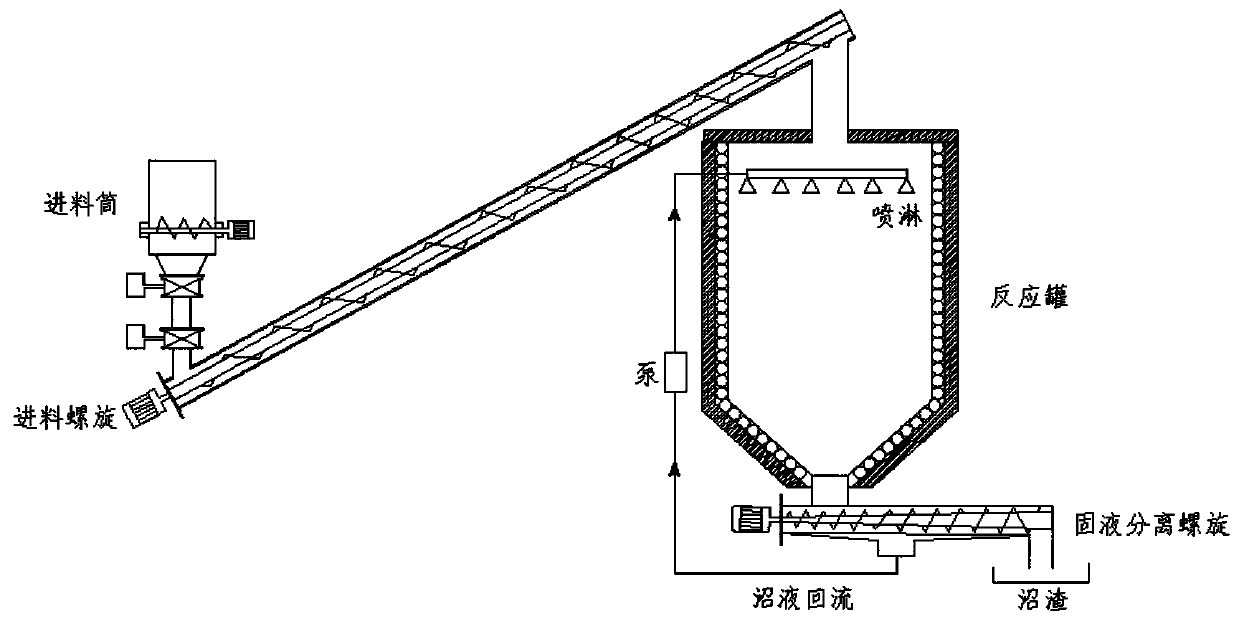

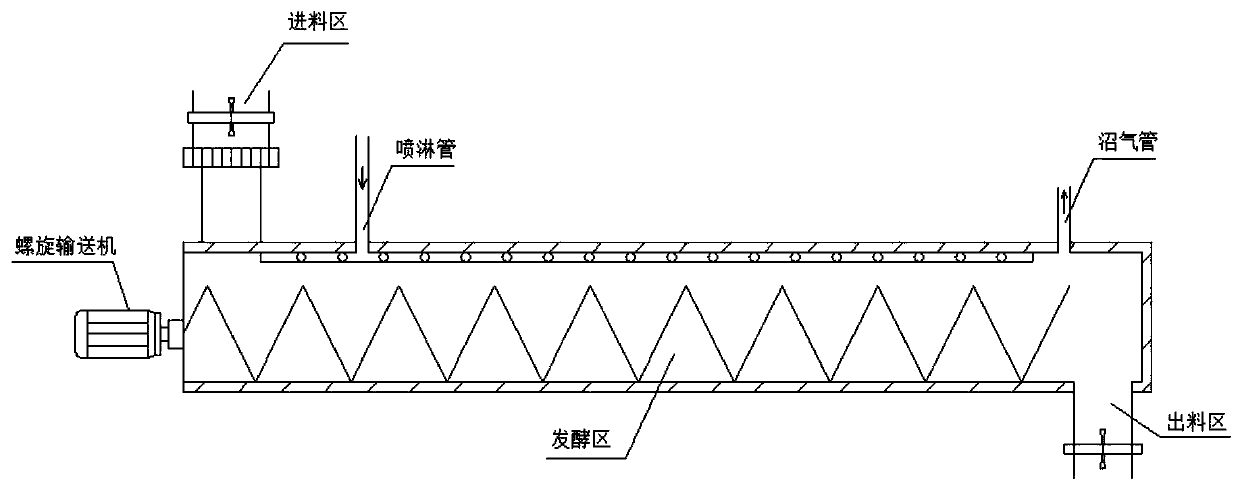

[0040] like Figure 4 and 5 As shown, the present embodiment provides a cross-flow type continuous dry fermentation device, comprising a fermentation device body 2, the top of the front end of the fermentation device body 2 is provided with a feed port, and the bottom of the rear end of the fermentation device body 2 is provided with There is a discharge port; the outer wall of the fermentation device body 2 is provided with a heat preservation device, specifically, the heat preservation device includes a heating coil arranged on the inner side of the outer wall of the fermentation device body 2, which is used to ensure the medium temperature or high temperature fermentation conditions required for anaerobic digestion , wherein, the heating coil generally adopts a hot water pipe, and a steam pipe can also be used; the interior of the fermentation device body 2 is provided with a stirring device, which can actively push materials, and the stirring device includes a stirring sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com