A kind of preparation method of high performance aluminum matrix composite material component

An aluminum-based composite material, high-performance technology, used in metal rolling, devices for coating liquid on the surface, grain processing, etc., can solve the adverse effects of material performance improvement, poor wettability between graphene and aluminum substrates, and inability to No shrinkage cavity, good internal structure compactness, and good interface bonding effect can be achieved by solving the problems of producing shape components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described below in conjunction with accompanying drawing:

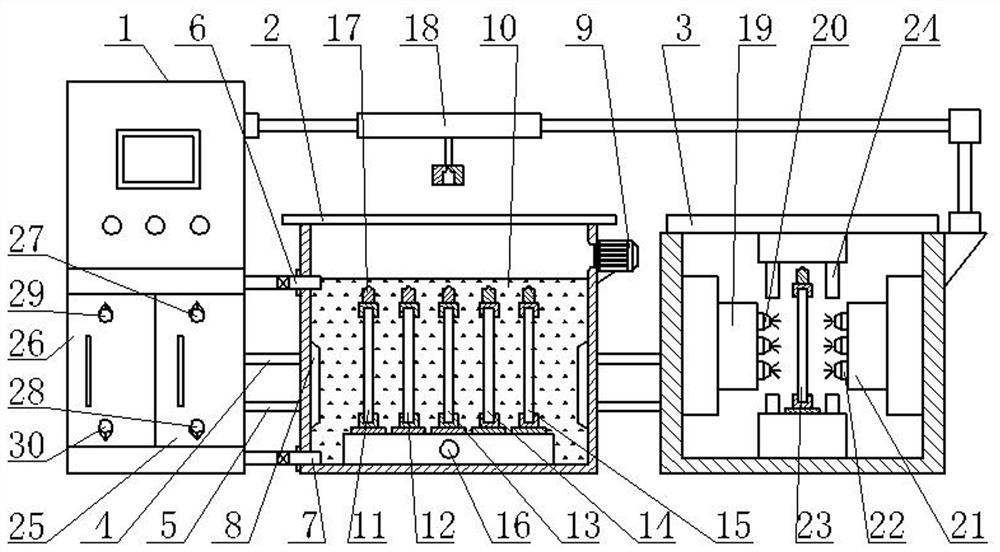

[0072] figure 1 As shown, it is the surface treatment of aluminum alloy plate and the state diagram of spraying carboxylated graphene on the surface of aluminum alloy plate after surface treatment; the whole set of equipment includes main control cabinet 1, surface treatment room 2, and surface spraying room 3;

[0073] The main control cabinet 1 controls the working state of the surface treatment chamber 2 through the first cable 4 and the second cable 5 on the one hand, and controls the working state of the surface spraying chamber 3 through the first cable 4 and the second cable 5 on the other hand;

[0074] A polyvinyl alcohol liquid storage tank 25 and a deionized water liquid storage tank 26 are respectively provided under the main control cabinet 1; a polyvinyl alcohol liquid inlet valve 27, a polyvinyl alcohol discharge valve, Liquid valve 28; the side wall of deio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com