Organic light-emitting material and organic light-emitting device

A light-emitting material, organic technology, applied in the direction of light-emitting materials, electro-solid devices, electrical components, etc., can solve the problems of mismatch of electrons and holes, poor luminous efficiency, poor injection effect, etc., to reduce the start-up voltage, Good thermodynamic stability, favorable effect of molecular packing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] The glass plate coated with the ITO transparent conductive layer is ultrasonically treated in a commercial cleaning agent, rinsed in deionized water, ultrasonically degreased in acetone-ethanol mixed solvent, baked in a clean environment until the water is completely removed, and then cleaned with ultraviolet light. Light and ozone cleaning, and bombardment of the surface with a beam of low-energy cations;

[0099] Place the above-mentioned glass substrate with the anode in a vacuum chamber, and evacuate to less than 10 -5 , HT-11 was vacuum evaporated on the anode layer as a hole injection layer, the evaporation rate was 0.1nm / s, and the evaporation film thickness was 10nm;

[0100] On the hole injection layer, HT-5 material was vacuum evaporated as the hole transport layer, the evaporation rate was 0.1nm / s, and the total film thickness was 80nm;

[0101] The light-emitting layer of the device is vacuum evaporated on the hole transport layer. The light-emitting layer ...

Embodiment 2-6

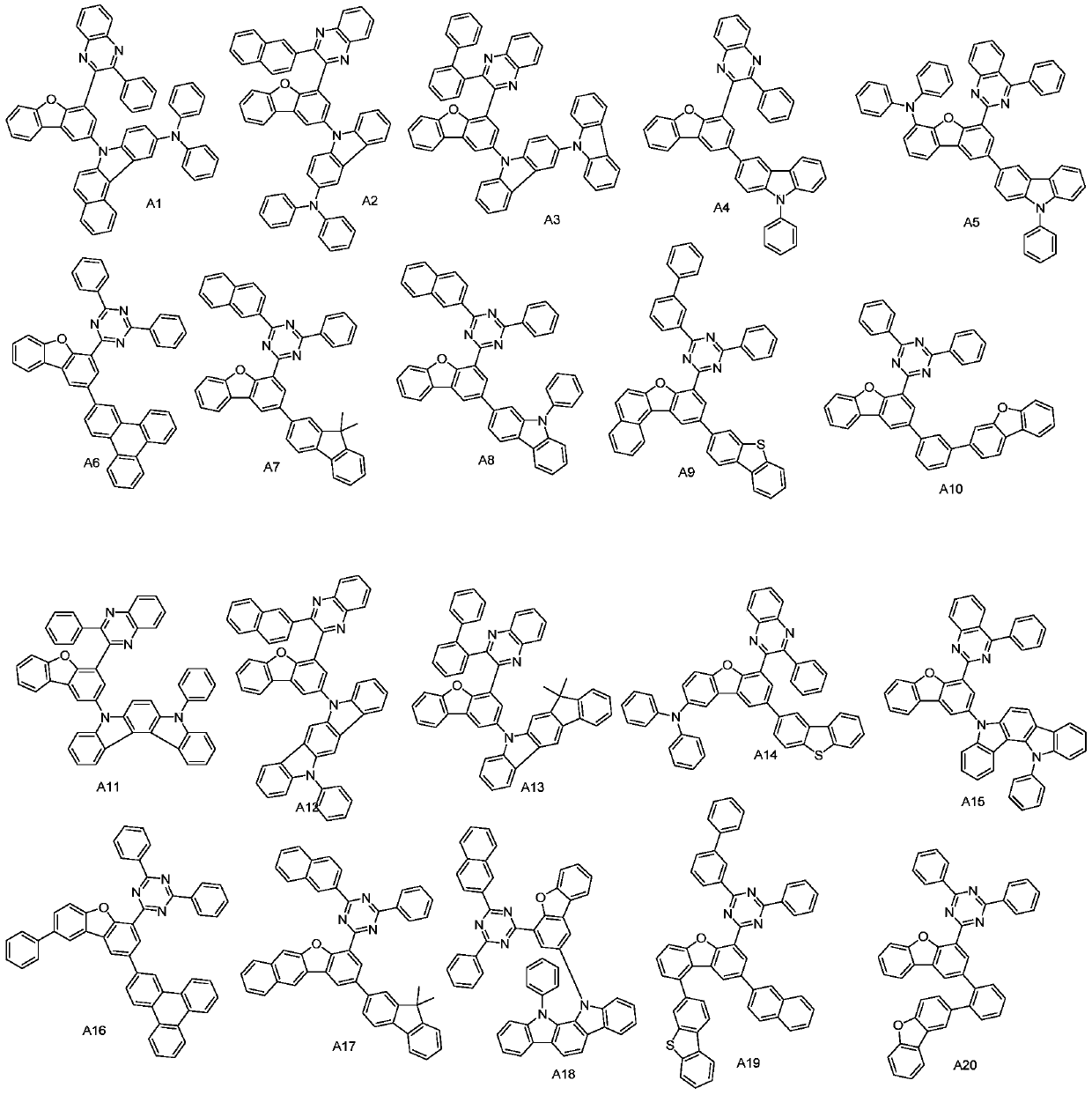

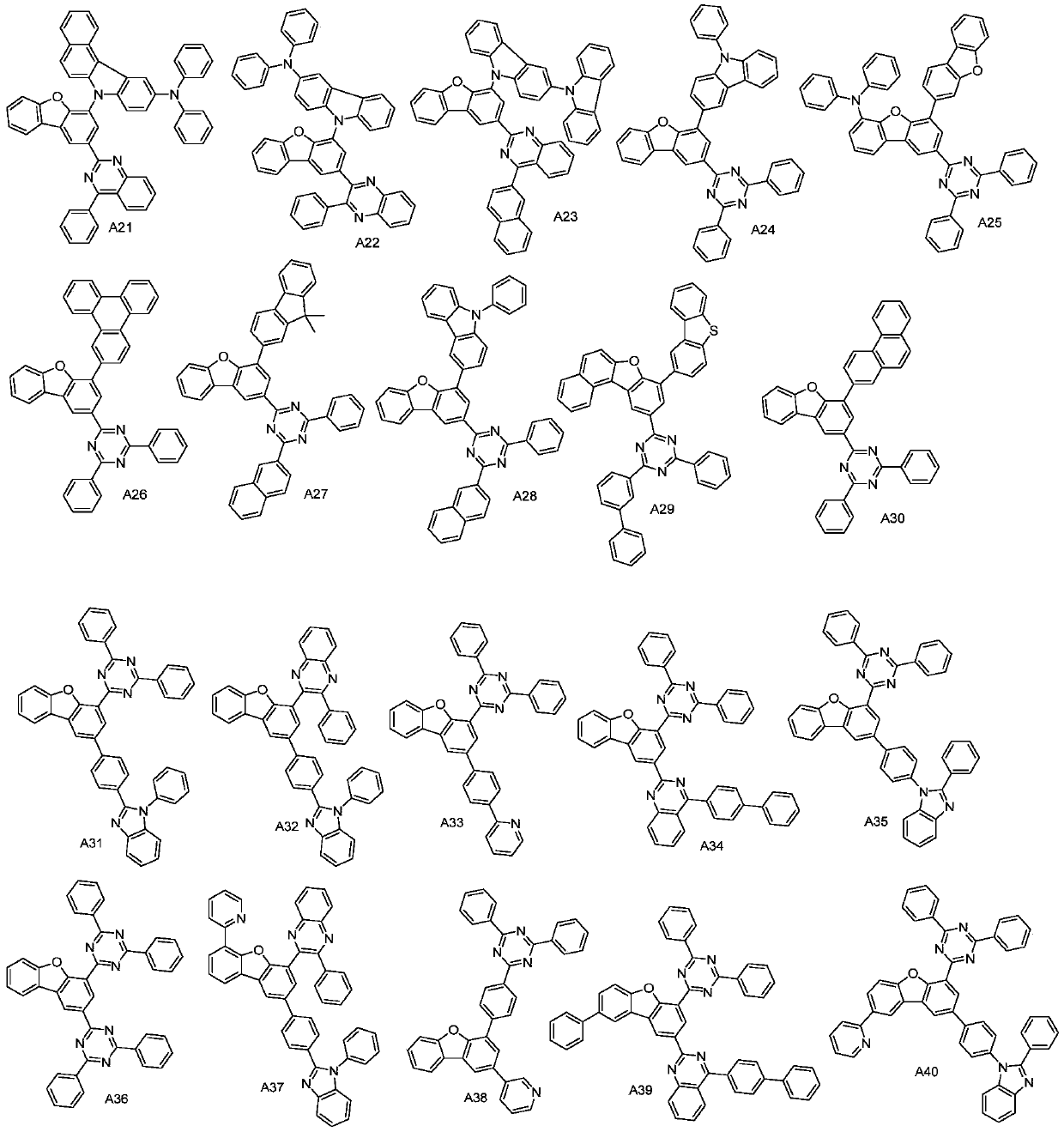

[0107] The organic light-emitting materials A6, A12, A19, A24 and A29 of the present application were respectively used as the host material of the light-emitting layer, and the rest were the same as in Example 1. The test results are shown in Table 1.

Embodiment 7

[0115] The glass plate coated with the ITO transparent conductive layer is ultrasonically treated in a commercial cleaning agent, rinsed in deionized water, ultrasonically degreased in acetone-ethanol mixed solvent, baked in a clean environment until the water is completely removed, and then cleaned with ultraviolet light. Light and ozone cleaning, and bombardment of the surface with a beam of low-energy cations;

[0116] Place the above-mentioned glass substrate with the anode in a vacuum chamber, and evacuate to less than 10 -5 , HT-11 was vacuum evaporated on the anode layer as a hole injection layer, the evaporation rate was 0.1nm / s, and the evaporation film thickness was 10nm;

[0117] On the hole injection layer, HT-5 material was vacuum evaporated as the hole transport layer, the evaporation rate was 0.1nm / s, and the total film thickness was 80nm;

[0118]The light-emitting layer of the device is vacuum-evaporated on the hole transport layer. The light-emitting layer i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com