Yellowing-resistant polyamide resin and preparation method thereof

A polyamide resin and polyamide technology, applied in the field of yellowing-resistant polyamide resin and its preparation, can solve the problems of segment breakage, uneven dispersion of additives, poor photo-oxidative stability, thermal-oxidative stability and poor weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

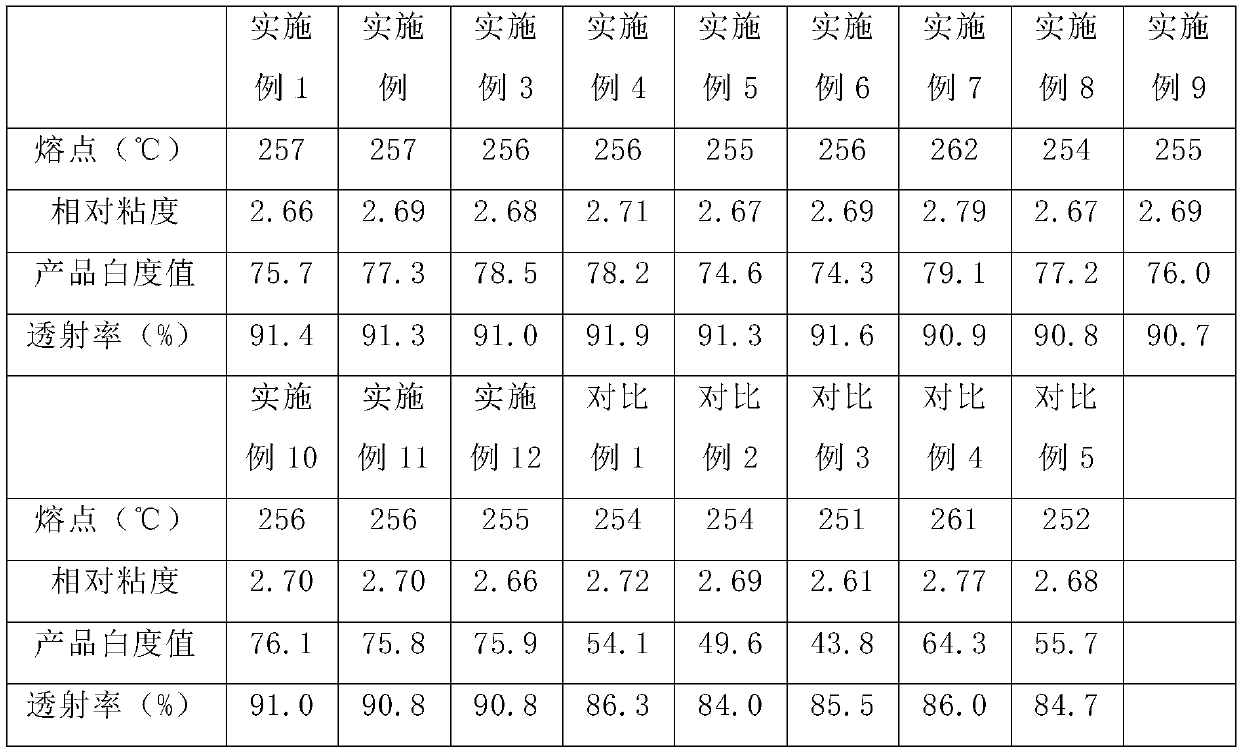

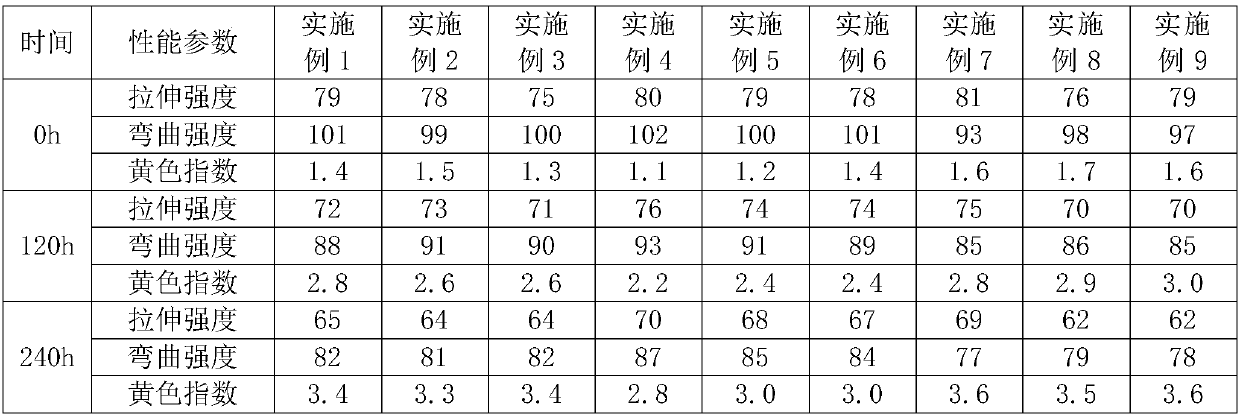

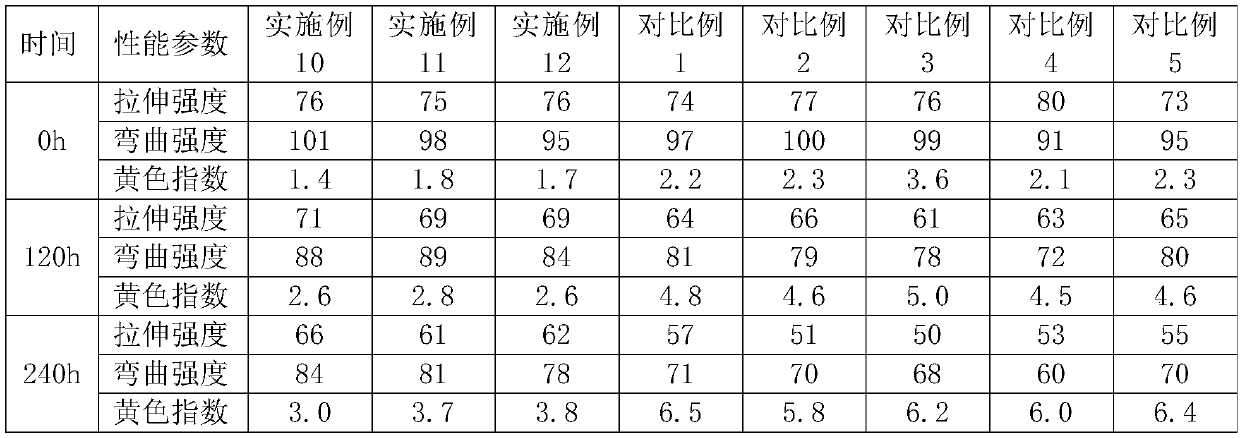

Examples

Embodiment a

[0098] Embodiment a pentamethylenediamine adipate

[0099] Replace the air in the 100-liter enamel salt-forming kettle by vacuuming and filling it with nitrogen three times, and protect it with nitrogen. Add 22kg of 1,5-pentanediamine (99.5% purity) and 1.5kg of deoxygenated water into the salt-forming kettle (Oxygen content is 0.01mg / L, accounting for 2.4% of the total weight of 1,5-pentanediamine and adipic acid), heat the mixture of 1,5-pentanediamine and water to 112, add 31.6kg of hexane Diacid (purchased from PetroChina Liaoyang Petrochemical Company, with a purity of 99%), keep the above temperature and under vigorous stirring, the reaction system becomes viscous, stir continuously for 3 hours, add acid and amine in small amounts to make the final dibasic acid amine salt The pH is 7.3.

[0100] Charge nitrogen into the polymerization kettle to a pressure of 0.2MPa (gauge pressure), start melting and discharging, and use a slicer to cool and slice to obtain white pentam...

Embodiment b

[0101] Embodiment b pentamethylenediamine adipate

[0102] Replace the air in the 100-liter enamel salt-forming kettle by vacuuming and filling nitrogen three times, and protect it with nitrogen, add 22kg 1,5-pentanediamine and 31.6kg adipic acid to the salt-forming kettle, heat, and then add 2.1kg deoxygenated water (oxygen content is 0.01mg / L, accounting for 4% of the total weight of 1,5-pentanediamine and adipic acid), control the temperature to 85°C, keep the above temperature and under strong stirring, the reaction system Become viscous, stir continuously for half an hour, add acid and amine in small amounts, and adjust the final pH of the dibasic acid amine salt to 7.0.

[0103] Charge nitrogen into the polymerization kettle to a pressure of 0.2 MPa (gauge pressure), start to melt and discharge, and use a slicer to cool and slice to obtain white pentamethylenediamine-adipate, with a weight of 44.1 kg and a purity of 99.5%. Dibasic acid amine salt crystals do not have th...

Embodiment c

[0104] Example c Pentamethylenediamine adipate

[0105] Replace the air in the 100-liter enamel salt-forming kettle by vacuuming and filling nitrogen three times, and protect it with nitrogen, add 22kg 1,5-pentanediamine and 31.6kg adipic acid to the salt-forming kettle, heat, and then add 4.3kg deoxygenated water (oxygen content 0.01mg / L, accounting for 8% of the total weight of 1,5-pentanediamine and adipic acid), control the temperature to 70°C, keep the above temperature and under strong stirring, the reaction system Become viscous, continue to stir for half an hour, add acid and amine in small amounts, adjust the final pH of the dibasic acid amine salt to 8.3.

[0106] Charge nitrogen into the polymerization kettle to a pressure of 0.2 MPa (gauge pressure), start melting and discharging, and use a slicer to cool and slice to obtain white pentamethylenediamine-adipate, with a weight of 44.7 kg and a purity of 99.5%. Dibasic acid amine salt crystals do not have the charact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Oxygen content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com