Sample pretreatment method for determining Amadori compound in food

A sample pretreatment and compound technology, applied in the field of analytical chemistry, to achieve the effect of removing interfering substances and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

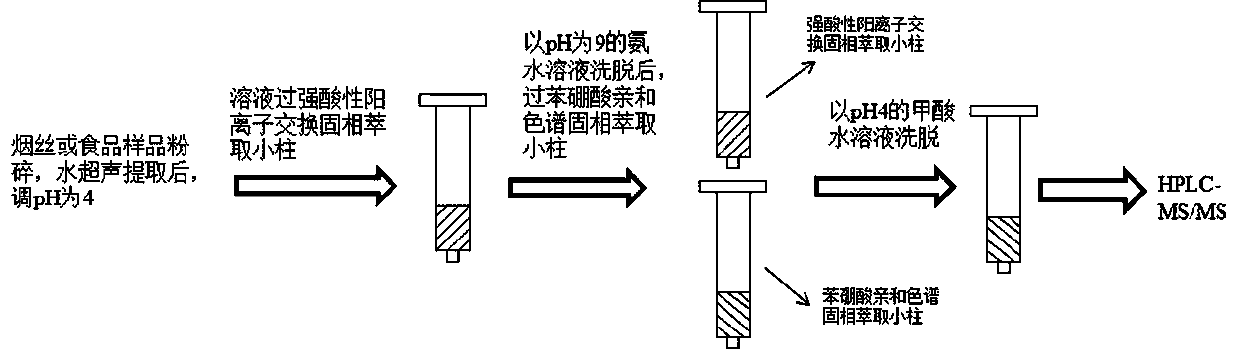

[0023] Crush the shredded tobacco through a 40-mesh sieve, take 100 mg and put it into a stoppered Erlenmeyer flask, add 20 mL of water, ultrasonically extract for 30 minutes and then filter, adjust the pH of the filtrate to 4 with 0.1 mol / L hydrochloric acid, and pass this solution through Oasis MCX solid-phase extraction After the (6mL) cartridge, the cartridge was connected in series with Bond Elut PBA solid-phase extraction, the Oasis MCX solid-phase extraction cartridge was eluted with ammonia solution at pH 9, and the eluate flowed through the Bond Elut PBA cartridge. The two small columns in series were disassembled, and the BondElut PBA small column was eluted with 3 mL of formic acid aqueous solution at pH 4, and the Amadori compound content was determined by HPLC-MS / MS. figure 1 Schematic diagram of the entire sample pretreatment process.

[0024] Chromatographic conditions: Atlantis T 3 chromatographic column (2.1×250 mm, 5 μm), mobile phase: 0.2% formic acid aqueou...

Embodiment 2

[0026] Dilute 1mL of soy sauce sample to 20mL and adjust the pH to 4 with 0.1 mol / L hydrochloric acid. After the solution is passed through an Oasis MCX solid phase extraction (6mL) cartridge, this cartridge is connected in series with Bond Elut PBA solid phase extraction to The Oasis MCX solid-phase extraction cartridge was eluted with ammonia solution at pH 9, and the eluate was passed through a Bond Elut PBA cartridge. The two small columns in series were disassembled, and the Bond Elut PBA small column was eluted with 3 mL of formic acid aqueous solution at pH 4, and the Amadori compound content was determined by HPLC-MS / MS.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com