Low-porosity positive pole piece, preparation method thereof and application of low-porosity positive pole piece in solid-state lithium metal battery

A positive pole piece and porosity technology, which is applied in the field of battery pole piece and lithium metal battery manufacturing, to achieve low internal resistance, high utilization rate, and increase battery energy density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

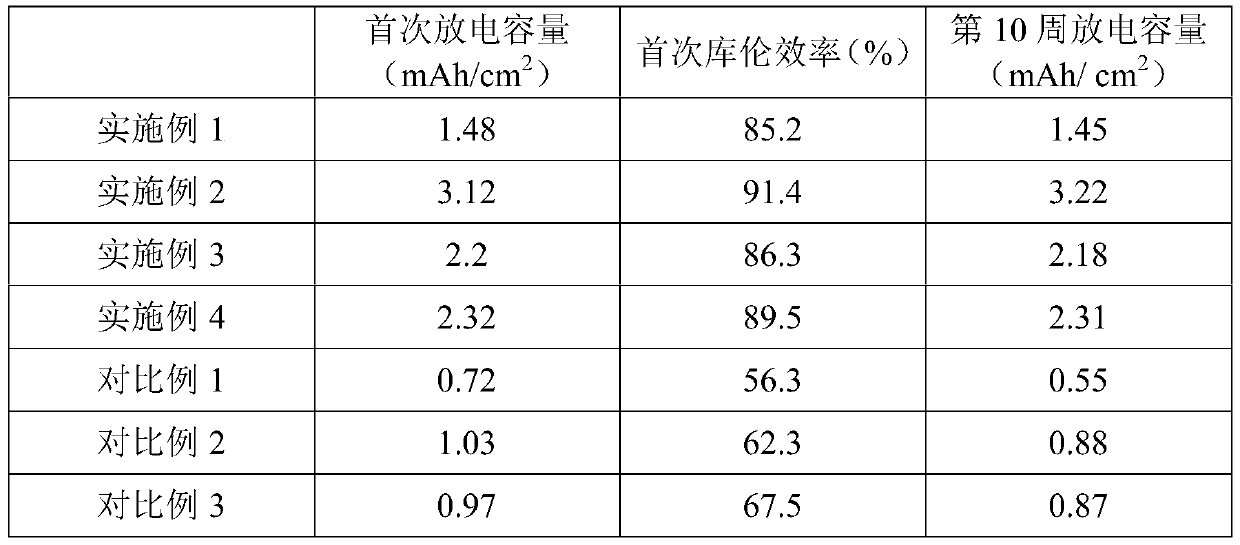

Embodiment 1

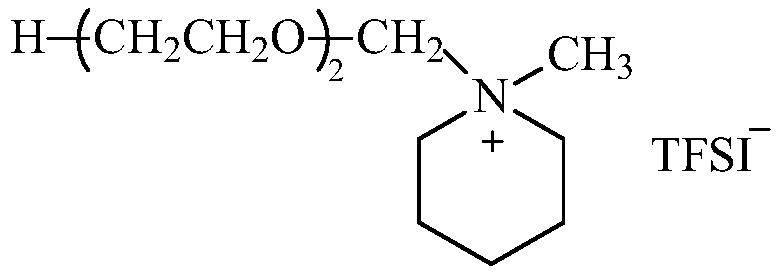

[0030]The electrode uses lithium cobaltate with a mass fraction of 80% of D50 of 5 μm and D90 of 8 μm as the active material, adding 5% of Super P, and the binder is composed of [8% PAALi + 0.2% nano-Al 2 o 3 +1% LGPS+1% LiFSI and 4.8% ionic liquid], the structure of the ionic liquid is as follows:

[0031]

[0032] Its preparation steps are as follows:

[0033] 1) In an environment with a dew point lower than -60°C, mix the above-mentioned adhesives evenly to obtain a viscous composite adhesive with room temperature conductivity > 10 -4 S / cm;

[0034] 2) Mix lithium cobaltate and Super P evenly with a dry powder mixer;

[0035] 3) Dry-mix the binder with the mixture obtained in 2), heat and mix the mixture evenly with the twin-screw, and then extrude onto the surface of the aluminum foil to complete double-sided coating;

[0036] 4) Roll the obtained pole piece to obtain a pole piece with a porosity of about 15% and a designed surface capacity of 1.5mAh / cm on one side ...

Embodiment 2

[0039] The active material is lithium iron phosphate with a D50 of 150nm, 3% Ketjen black is added as a conductive agent, the main body of the binder polymer is PEO with a number average molecular weight of 200,000, and the ionic liquid is Li(G3) with a mass fraction of 6.8%. TFSI, other ratios are the same as in Example 1, that is, active material: conductive agent: binder = 80:3:17.

[0040] The preparation steps of the electrode sheet are the same as in Example 1, but the current collector is made of nickel foam, and the sheet is made by one coating. The capacity behind the pole piece rolling is 3.2mAh / cm 2 (both sides), porosity 19%.

[0041] The LLZO solid electrolyte sheet with a thickness of 0.5mm was used to form a button battery with the above-mentioned positive electrode and lithium sheet, and its charge and discharge performance was tested at 50°C and 0.1C.

Embodiment 3

[0043] The positive electrode uses NCM622 single crystal with a D50 of 3 μm, 2% Ketjen Black + 3% carbon nanotubes as the conductive agent, and the binder consists of 8% PVDF-HFP + 0.5% LiBF 4 +0.5%LiBOB+0.2%LiPF 6 +4%PP13TFSI+0.3%SiO 2 +1.5% LLZO composition, that is, active material: conductive agent: binder = 80:5:15.

[0044] During the preparation process, add the components of the binder to the NMP in proportion, stir at room temperature for 5 hours, then add the dry powder and mix the active material and the conductive agent uniformly. The solid content of the system is controlled at 50% to 70%. Coated on aluminum foil with a rough surface in an environment below -40°C, coated on both sides, dried and then hot-pressed at 80°C to obtain a porosity of 18.7% and a capacity of about 2.2mAh / cm on one side 2 pole piece.

[0045] The LLZO solid electrolyte sheet with a thickness of 0.5mm was used to form a button battery with the above-mentioned positive electrode and lithi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity at room temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com