Milk edible fungus ice cream with effects of dispelling effects of alcohol and protecting liver and preparation method of milk edible fungus ice cream

A technology of edible fungus and ice cream, which is applied in the field of milk edible fungus ice cream and its preparation, can solve the problems that milk edible fungus ice cream has not been seen, the composition is unfavorable for the quality control of food preparation process, etc., and achieve fine structure, uniform texture and good application prospects good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

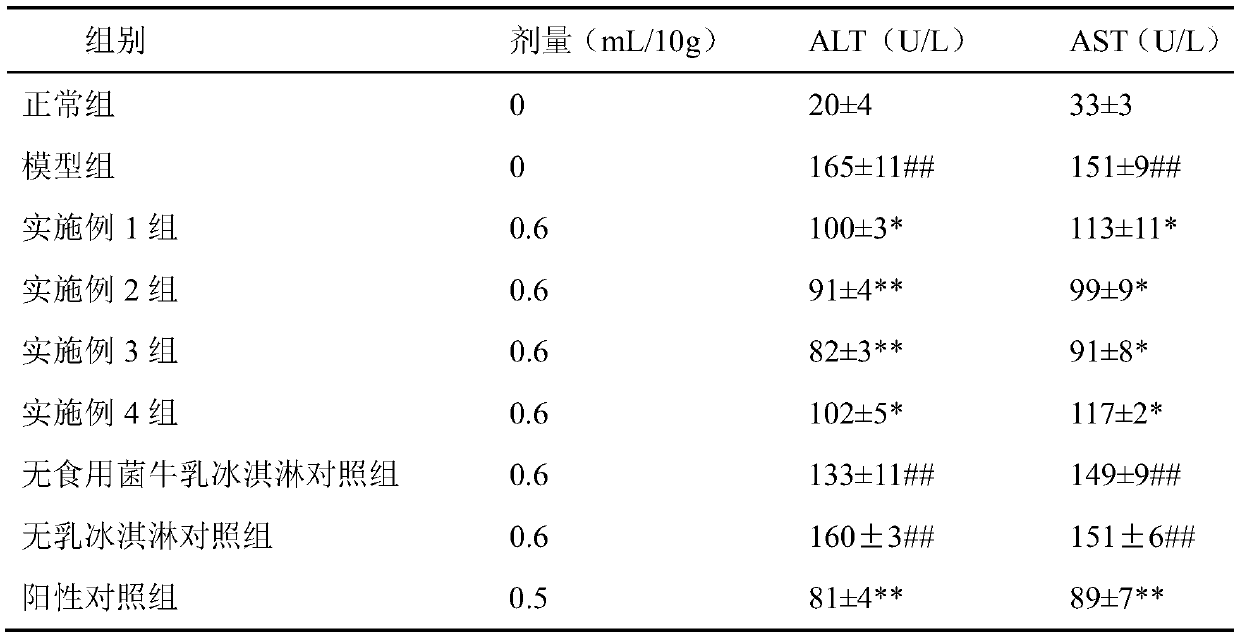

Examples

Embodiment 1

[0028] Raw material ratio (parts by weight) of milk edible mushroom ice cream: 35 parts of fresh milk, 4 parts of white fungus superfine powder, 3 parts of white sugar, 100 parts of water, 0.01 part of xanthan gum, 0.01 part of locust bean gum, acid-resistant carboxymethyl 0.02 part of sodium cellulose, 0.05 part of guar gum, and 0.05 part of monoglyceride.

[0029] The preparation steps of milk edible mushroom ice cream:

[0030] (1) Mixing: Stir white sugar, xanthan gum, locust bean gum, acid-resistant sodium carboxymethylcellulose, guar gum and monoglyceride with water (30-60°C) and fresh milk according to the weight ratio Mix evenly, then add tremella superfine powder, stir and mix evenly to obtain a mixed liquid.

[0031] (2) Sterilization: pasteurize the mixed solution, wherein the heating temperature is 70° C. and kept for 15 minutes.

[0032] (3) Homogenization: the pasteurized mixed solution is subjected to high-pressure homogenization at 15MPa and 66°C.

[0033] (...

Embodiment 2

[0036] Raw material composition ratio (parts by weight) of milk edible mushroom ice cream: 47 parts of fresh milk, 1 part of superfine powder of Pleurotus eryngii, 4 parts of white sugar, 90 parts of water, 0.018 part of xanthan gum, 0.017 part of locust bean gum, acid-resistant carboxyl 0.026 part of sodium methylcellulose, 0.08 part of guar gum, and 0.07 part of monoglyceride.

[0037] The preparation steps of milk edible mushroom ice cream:

[0038] (1) Mixing: Stir white sugar, xanthan gum, locust bean gum, acid-resistant sodium carboxymethylcellulose, guar gum and monoglyceride with water (30-60°C) and fresh milk according to the weight ratio Mix evenly, then add superfine powder of king oyster mushroom, stir and mix evenly to obtain a mixed solution.

[0039] (2) Sterilization: pasteurize the mixed solution, wherein the heating temperature is 70° C. and kept for 15 minutes.

[0040] (3) Homogenization: The pasteurized mixed solution is subjected to high-pressure homoge...

Embodiment 3

[0044] Raw material ratio (parts by weight) of milk edible mushroom ice cream: 60 parts of fresh milk, 1.5 parts of superfine black fungus powder, 7 parts of white sugar, 90 parts of water, 0.023 parts of xanthan gum, 0.025 parts of locust bean gum, acid-resistant carboxymethyl 0.02 part of sodium cellulose base, 0.1 part of guar gum, and 0.1 part of monoglyceride.

[0045] The preparation steps of milk edible mushroom ice cream:

[0046] (1) Mixing: Stir white sugar, xanthan gum, locust bean gum, acid-resistant sodium carboxymethylcellulose, guar gum and monoglyceride with water (30-60°C) and fresh milk according to the weight ratio Mix evenly, then add black fungus superfine powder, stir and mix evenly to obtain a mixed solution.

[0047] (2) Sterilization: pasteurize the mixed solution, wherein the heating temperature is 70° C. and kept for 15 minutes.

[0048] (3) Homogenization: The pasteurized mixed solution is subjected to high-pressure homogenization at 15MPa and 65°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com