Rana japonica oil gel food and preparation method thereof

A technology of wood frog oil and gel state, which is applied in the field of food processing, can solve the problems of destroying the gel structure of wood frog oil and the inability to form gel, etc., and achieve the effect of improving gel characteristics, increasing strength and rich nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

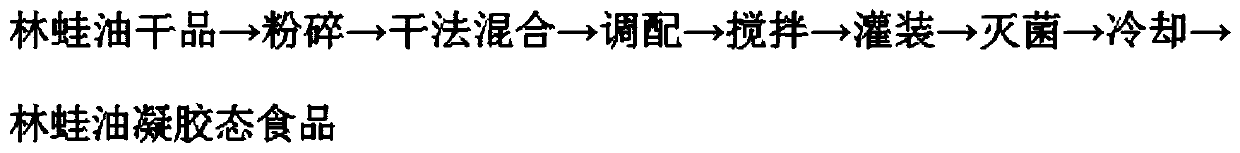

Method used

Image

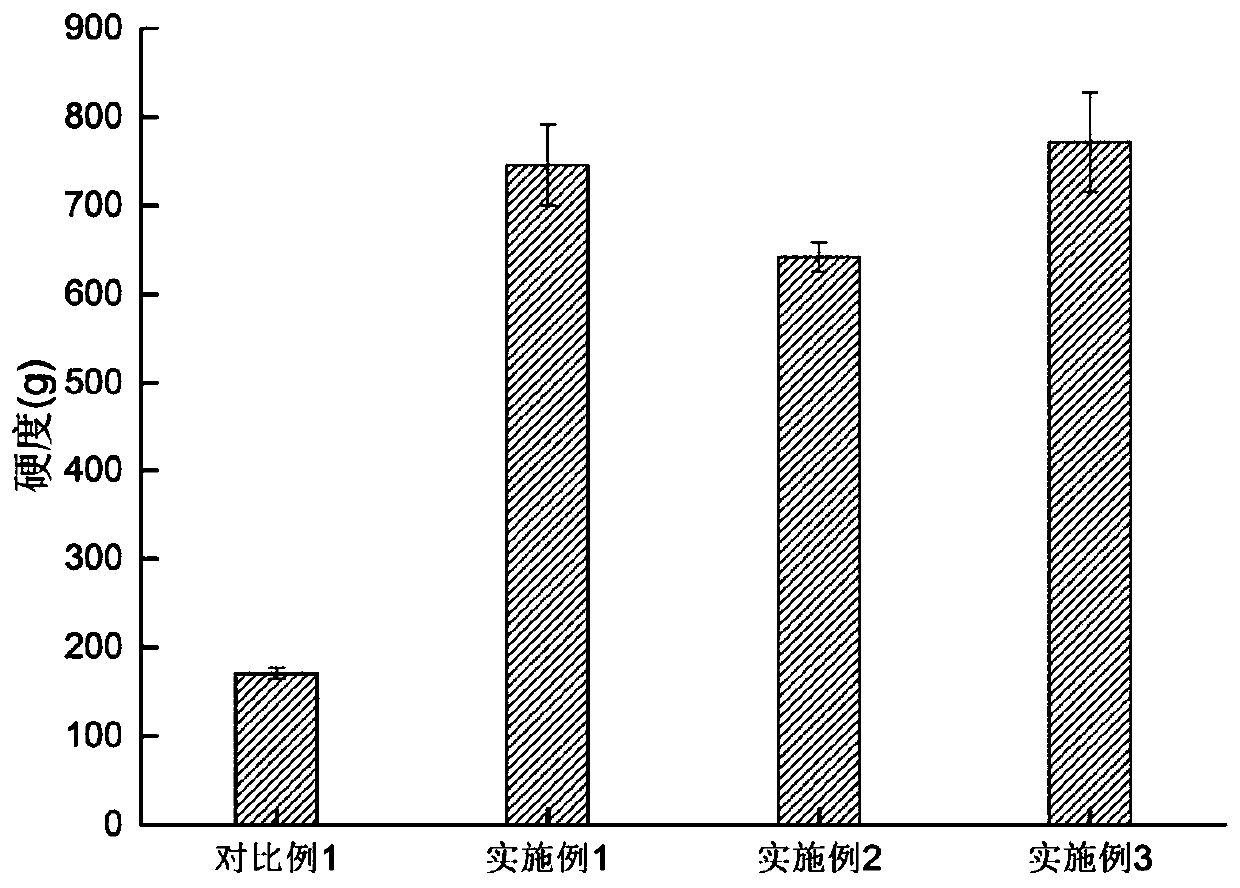

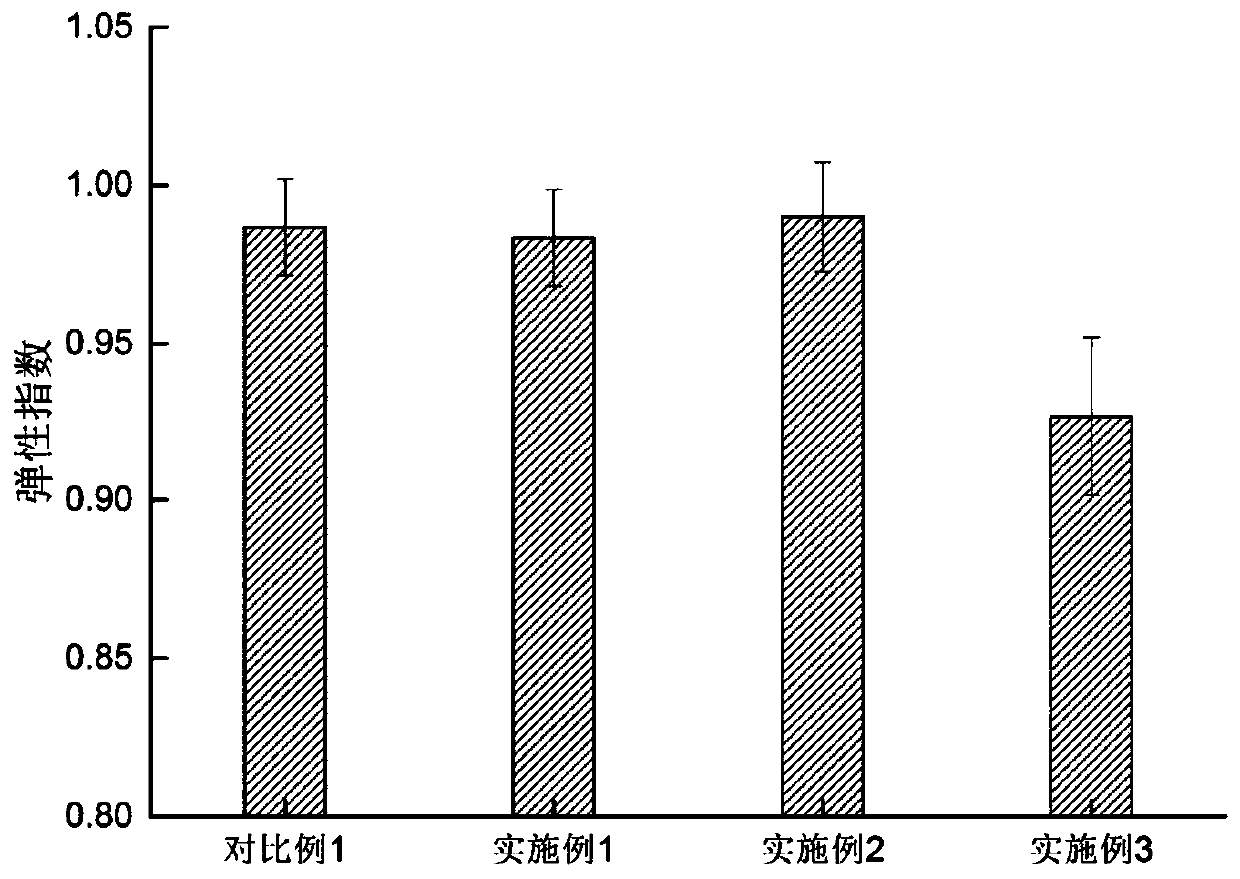

Examples

Embodiment 1

[0026] It consists of the following components by mass percentage: 0.98% of wood frog oil, 98.46% of purified water, 0.15% of xanthan gum, 0.15% of konjac gum, 0.06% of compound sweetener, 0.2% of pineapple essence, and 0.0005% of lemon yellow pigment .

[0027] Concrete preparation process comprises the following steps:

[0028] (1) Pulverization: Remove impurities such as black fascia from the selected dried wood frog oil, pulverize and sieve (above 40 mesh) to obtain wood frog oil powder;

[0029] (2) dry mixing: the wood frog oil powder obtained in step (1) is directly mixed with xanthan gum and konjac gum powder, fully stirred evenly, and mixed powder is obtained;

[0030] (3) Deployment: Add pineapple essence, compound sweetener and lemon yellow pigment to the purified water in the batching tank and stir evenly;

[0031] (4) Stirring: add the mixed powder obtained in step (2) into the prepared feed liquid, and stir to obtain glue.

[0032] (5) Filling: fast filling an...

Embodiment 2

[0036] It consists of the following components by mass percentage: 0.98% of wood frog oil, 98.24% of purified water, 0.2% of xanthan gum, 0.2% of konjac gum, 0.09% of compound sweetener, 0.29% of mango essence, and 0.0005% of lemon yellow pigment .

[0037] Concrete preparation process comprises the following steps:

[0038] (1) Pulverization: Remove impurities such as black fascia from the selected dried wood frog oil, pulverize and sieve (above 40 mesh) to obtain wood frog oil powder;

[0039] (2) dry mixing: the wood frog oil powder obtained in step (1) is directly mixed with xanthan gum and konjac gum powder, fully stirred evenly, and mixed powder is obtained;

[0040] (3) Deployment: Add mango essence, compound sweetener and lemon yellow pigment to the purified water in the batching tank and stir evenly;

[0041] (4) Stirring: add the mixed powder obtained in step (2) into the prepared feed liquid, and stir to obtain glue.

[0042] (5) Filling: fast filling and sealing...

Embodiment 3

[0046] It consists of the following components by mass percentage: 0.98% of wood frog oil, 98.02% of purified water, 0.25% of xanthan gum, 0.25% of konjac gum, 0.11% of compound sweetener, 0.39% of apple essence, and 0.0005% of green pigment .

[0047] Concrete preparation process comprises the following steps:

[0048] (1) Pulverization: Remove impurities such as black fascia from the selected dried wood frog oil, pulverize and sieve (above 40 mesh) to obtain wood frog oil powder;

[0049] (2) dry mixing: the wood frog oil powder obtained in step (1) is directly mixed with xanthan gum and konjac gum powder, fully stirred evenly, and mixed powder is obtained;

[0050] (3) Deployment: Add apple essence, compound sweetener, and fruit green pigment to the purified water in the batching tank and stir evenly;

[0051] (4) Stirring: add the mixed powder obtained in step (2) into the prepared feed liquid, and stir to obtain glue.

[0052] (5) Filling: fast filling and sealing of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Chewiness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com