Process for recycling marigold production waste liquid

A technology of waste liquid recovery and marigold, applied in application, liquid fertilizer, biological organic part treatment, etc., can solve the problems of harmfulness to human body or animals and plants, unsafe recovery of active ingredients, waste of resources, etc. Ecological circular agriculture, the effect of improving processing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

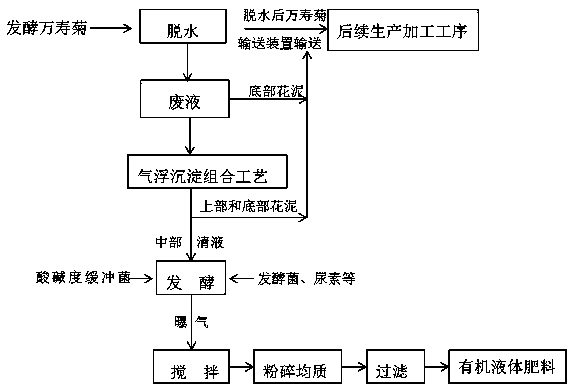

[0042] Step 1. During the processing of marigolds, fermented marigolds have a high water content, and are dehydrated by pressing. After pressing, the marigold flower mud is transported to drum drying by a scraper for subsequent processing, and the production waste liquid is to be treated;

[0043] Step 2. After the production waste liquid to be treated in the previous step is subjected to natural precipitation and separation, the bottom flower mud is returned to the scraper to be transported into the subsequent production and processing process, and the broken flower mud that is difficult to separate is to be processed;

[0044] Step 3: After the first separation of natural precipitation, the broken flowers contained in the middle and upper parts of the production waste liquid are separated, and the production waste liquid is separated again through the combined process of air flotation and sedimentation, and the air is pressurized to 0.25Mpa by pressurized dissolved air flotati...

Embodiment 2

[0049] Step 1. During the processing of marigolds, fermented marigolds have a high water content, and are dehydrated by pressing. After pressing, the marigold flower mud is transported to drum drying by a scraper for subsequent processing, and the production waste liquid is to be treated;

[0050] Step 2. After the production waste liquid to be treated in the previous step is naturally precipitated and separated, the bottom flower mud is returned to the scraper to be transported into the subsequent production and processing process, and the broken flower mud that is difficult to separate is to be processed;

[0051] Step 3: After the primary separation of natural precipitation, the broken flowers contained in the middle and upper parts of the production waste liquid are carried out, and the production waste liquid is subjected to secondary separation through the air flotation and sedimentation combined process, and the air is pressurized to 0.4Mpa by pressurized dissolved air fl...

Embodiment 3

[0056] Step 1. During the processing of marigolds, fermented marigolds have a high water content, and are dehydrated by pressing. After pressing, the marigold flower mud is transported to drum drying by a scraper for subsequent processing, and the production waste liquid is to be treated;

[0057] Step 2. After the production waste liquid to be treated in the previous step is naturally precipitated and separated, the bottom flower mud is returned to the scraper to enter the subsequent production and processing process, and the broken flower mud that is difficult to separate is to be processed;

[0058] Step 3: After the first separation of natural precipitation, the broken flowers contained in the middle and upper parts of the production waste liquid are separated, and the production waste liquid is separated again through the combined process of air flotation and sedimentation, and the air is pressurized to 0.55Mpa by pressurized dissolved air flotation to make the air It is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com