Blast furnace gas adsorption desulfurization method and device

A blast furnace gas, adsorption desulfurization technology, applied in the removal of gas pollutants, gas dust removal, combustible gas purification, etc., can solve the problems of high investment cost, unstable desulfurization effect, easy catalyst failure, etc., to simplify the purification system , save investment, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

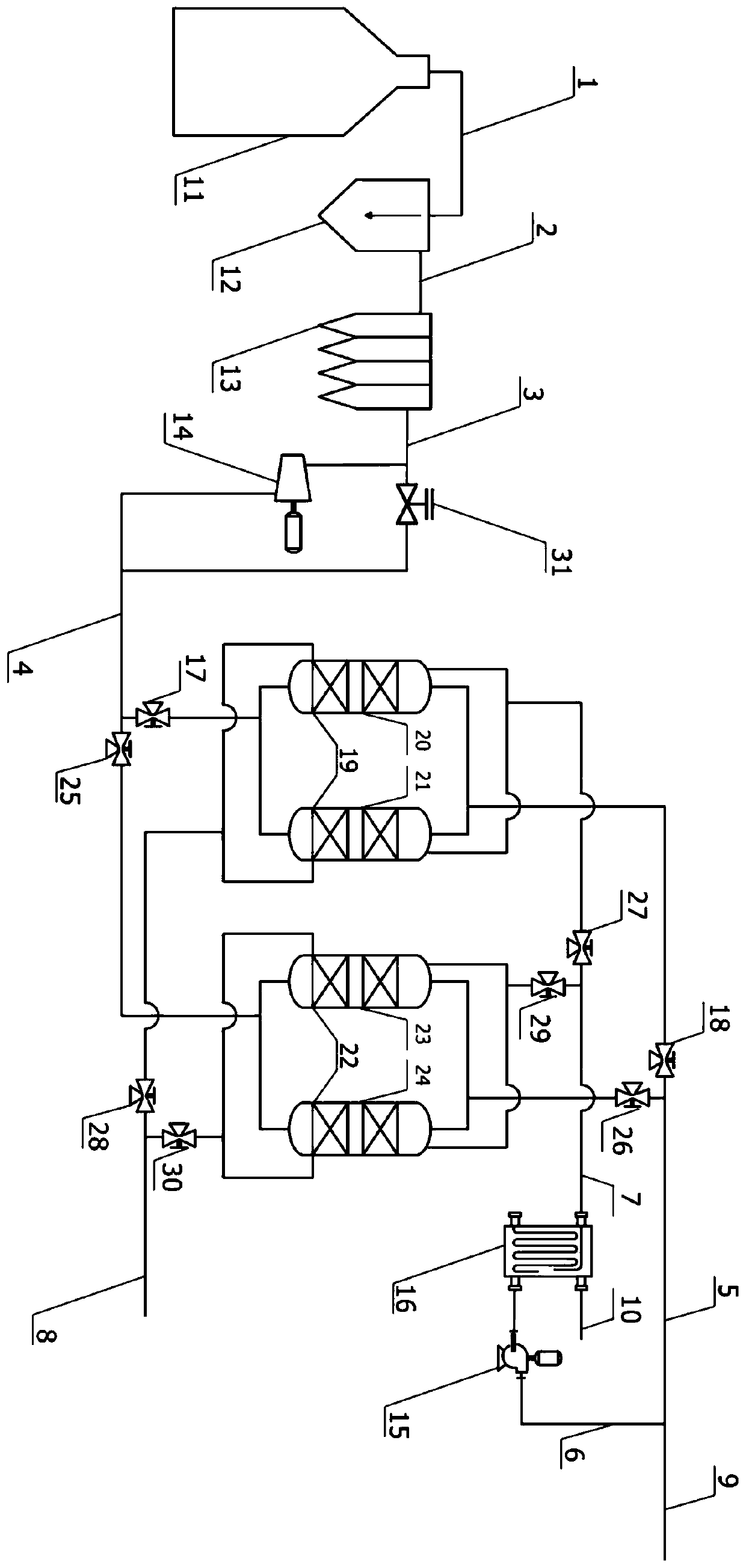

[0051] refer to figure 1 , a blast furnace gas adsorption desulfurization device system of the present invention, the blast furnace gas is discharged from the top of the blast furnace 11, enters the gravity dust collector 12 to remove large particle dust, and after the gravity dust collector 12 is discharged, enters the dry bag filter 13 to remove smaller particles After the dust is discharged, it enters the TRT residual pressure power generation device 14 and the pressure regulating valve group 31, and forms low-pressure blast furnace gas after the residual pressure is utilized. The low-pressure blast furnace gas enters the adsorption fine desulfurization working tower group I19 for adsorption and fine desulfurization to form clean blast furnace gas. To gas users in the plant area.

[0052] According to the above steps, when the sulfur capacity of the adsorbent in the working tower group I19 is saturated, the working tower group I19 enters the thermal desorption state, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com