Multi-element small-amount degradable antibacterial magnesium alloy and preparation method thereof

An antibacterial magnesium and magnesium alloy technology, applied in the field of light metal materials, can solve problems such as restricting the application of magnesium alloys, uncontrollable degradation rate, weakening mechanical properties, etc., and achieve the effects of easy control, improved antibacterial performance, and reduced degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

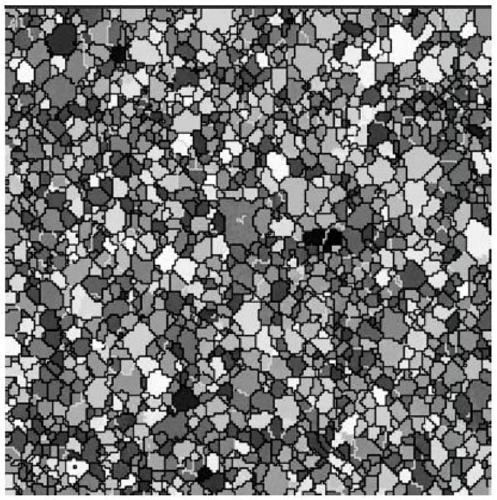

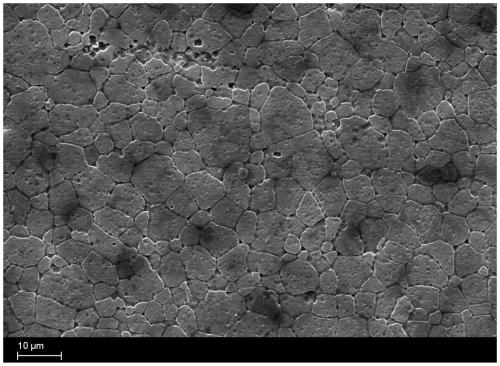

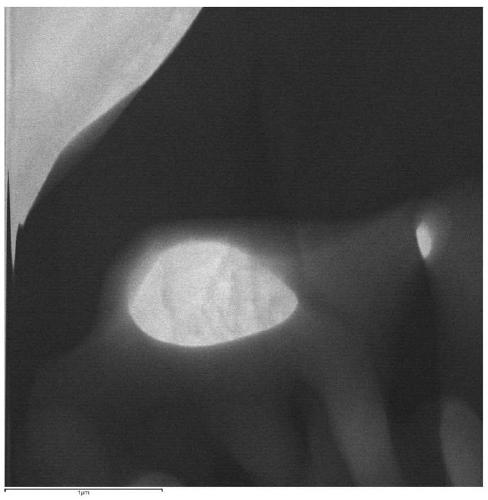

Image

Examples

Embodiment 1

[0064] Step 1. Weigh each component and preheat, and weigh according to weight fraction: Ca: 0.4%, Zn: 0.8%, Ag: 0.3%, Se: 0.02%, Mn: 0.05%, and the balance is Mg and unavoidable Impurities ≤ 0.2%; put the weighed raw materials into an oven with high-purity argon, and heat at 60°C for 30min;

[0065] Among them, Se through Ag 2 Se way to add;

[0066] In the present invention, considering burning loss, as a kind of preference, the actual addition amount of Zn is 1.05 times of the above-mentioned content;

[0067] Step 2, alloy melting and casting, put the high-purity magnesium ingot into the high-purity graphite crucible of the high-vacuum-atmosphere protection melting furnace, and vacuumize to 2×10 -4 Pa, and then filled with 0.06MPa high-purity argon as a protective atmosphere, heated to complete melting under the protection of argon, after adding Mg-Mn master alloy, Mg-Ca master alloy and high-purity silver ingot at 670 ° C, the first Raise the temperature to 705°C until...

Embodiment 2

[0072] Step 1. Weigh each component and preheat, and weigh according to weight fraction: Ca: 0.9%, Zn: 1.0%, Ag: 1.35%, Se: 0.08%, Mn: 0.1%, and the balance is Mg and unavoidable Impurities ≤ 0.2%; put the weighed raw materials into an oven with high-purity argon, and heat at 100°C for 20 minutes;

[0073] Among them, Se through Ag 2 Se way to add;

[0074] In the present invention, considering burning loss, as a kind of preference, the actual addition amount of Zn is 1.05 times of the above-mentioned content;

[0075] Step 2, alloy melting and casting, put the high-purity magnesium ingot into the high-purity graphite crucible of the high-vacuum-atmosphere protection melting furnace, and evacuate to 5×10 -4 Pa, and then filled with 0.05MPa high-purity argon as a protective atmosphere, heated to complete melting under the protection of argon, after adding Mg-Mn master alloy, Mg-Ca master alloy and high-purity silver ingot at 675 ° C, the first Raise the temperature to 700°C ...

Embodiment 3

[0080] Step 1. Weigh each component and preheat, and weigh according to weight fraction: Ca: 1.2%, Zn: 1.2%, Ag: 2.0%, Se: 0.2%, Mn: 0.15%, and the balance is Mg and unavoidable Impurities ≤ 0.2%; put the weighed raw materials into an oven with high-purity argon, and heat at 100°C for 20 minutes;

[0081] Among them, Se through Ag 2 Se way to add;

[0082] In the present invention, considering burning loss, as a kind of preference, the actual addition amount of Zn is 1.05 times of the above-mentioned content;

[0083] Step 2, alloy melting and casting, put the high-purity magnesium ingot into the high-purity graphite crucible of the high-vacuum-atmosphere protection melting furnace, and evacuate to 3×10 -4 Pa, and then filled with 0.08MPa high-purity argon as a protective atmosphere, heated to complete melting under the protection of argon, after adding Mg-Mn master alloy, Mg-Ca master alloy and high-purity silver ingot at 690 ° C, the first Raise the temperature to 720°C u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com