Coal-fired catalyst as well as preparation method and application thereof

A coal-burning catalyst and solvent technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of low coal efficiency, large emissions, and environmental pollution. and other problems to achieve the effect of improving utilization, increasing calorific value, and expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The second aspect of the present invention provides a method for preparing a coal-burning catalyst as described above, which includes the following steps: adding the inorganic acid to one-half of the solvent, mixing, adding catalytic components and sulfur-fixing components, stirring, and adding the remaining amount of solvent to obtain the coal-fired catalyst.

[0052] The third aspect of the present invention provides an application of the above-mentioned coal-fired catalyst in the field of cement production or coal power.

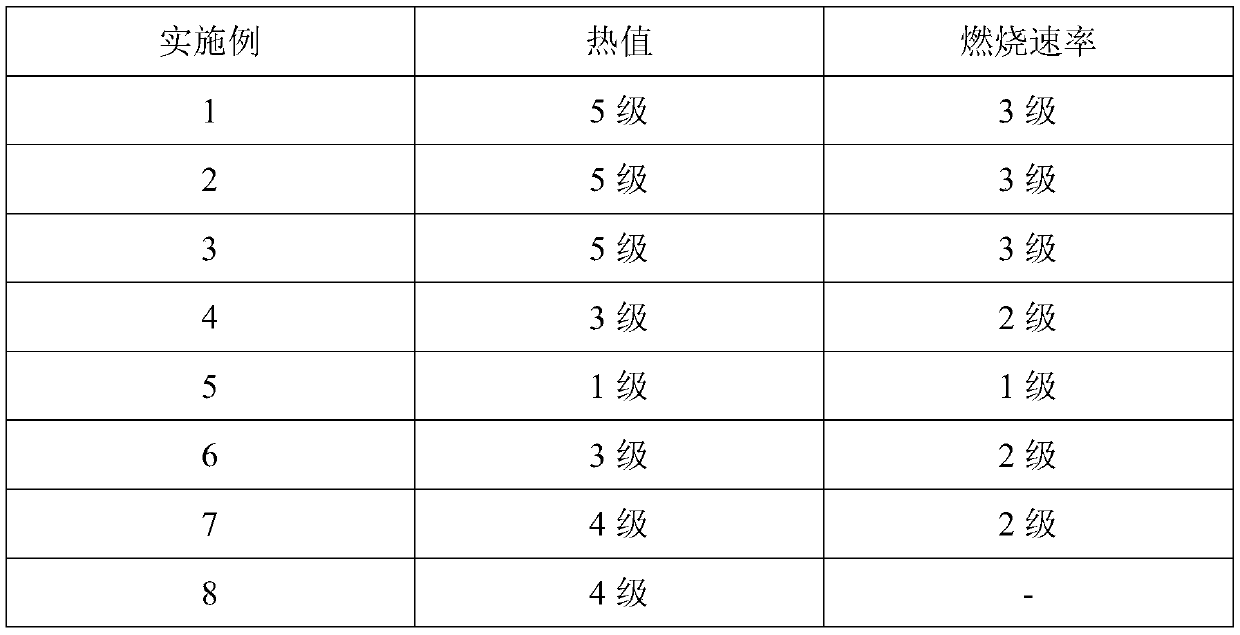

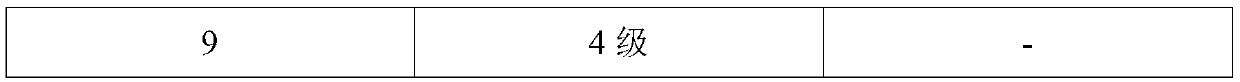

Embodiment 1

[0057] Embodiment 1 of the present invention provides a kind of coal-burning catalyst, and the preparation raw material of described coal-burning catalyst comprises 10% mineral acid, 4% catalytic component, 0.3% sulfur-fixing component and the balance solvent by weight percentage, and described The inorganic acid is 68wt% nitric acid aqueous solution, the catalytic components include transition metal oxides and rare earth metal oxides, the weight ratio is 1:0.15, the transition metal oxides include nickel oxide, manganese trioxide and copper oxide, the weight ratio 0.9:1.1:1, the transition metal oxide also includes dicobalt seoxide, diiron sequester and zinc oxide, the weight ratio is 1:1.7:1.8, the weight ratio of copper oxide and dicobalt seoxide is 1:0.14, the rare earth metal oxide includes dilanthanum trioxide and cerium oxide in a weight ratio of 1.4:1, the sulfur-fixing component is calcium oxide, and the solvent is water.

[0058] This example also provides the prepar...

Embodiment 2

[0060] Embodiment 2 of the present invention provides a kind of coal-burning catalyst, and the preparation raw material of described coal-burning catalyst comprises 13% inorganic acid, 6% catalytic component, 0.5% sulfur-fixing component and the balance solvent by weight percentage, described The inorganic acid is 68wt% nitric acid aqueous solution, the catalytic components include transition metal oxides and rare earth metal oxides, the weight ratio is 1:0.25, the transition metal oxides include nickel oxide, manganese trioxide and copper oxide, the weight ratio 1:1.3:1, the transition metal oxide also includes dicobalt seoxide, diiron sequester and zinc oxide, the weight ratio is 1:2:2.2, the weight ratio of the copper oxide and dicobalt seoxide is 1:0.18, the rare earth metal oxide includes dilanthanum trioxide and cerium oxide in a weight ratio of 1.6:1, the sulfur-fixing component is calcium oxide, and the solvent is water.

[0061] This example also provides the preparat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com