Grinding wheel applied to cylindrical grinding of silicon carbide crystal bar and preparation method thereof

A silicon carbide crystal, rod outer circle technology, applied in grinding/polishing equipment, grinding devices, bonded grinding wheels, etc., can solve the problems of material removal rate and surface quality difficulty, high crystal growth cost, crystal rod fracture, etc. , to increase the self-sharpening, increase the consistency of grinding consumption, and increase the fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

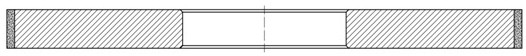

[0037] To make 1A1-400×30×127×5 cylindrical grinding wheels with a particle size of 80#, see figure 1 .

[0038] 1. Formula: According to the following table:

[0039] 1A1-400×30×127×5 Granularity 80# Cylindrical Grinding Coarse Grinding Wheel Formula

[0040]

[0041] Second, the production process

[0042] 2.1 Weigh the materials with the above formula ratio, the total weight is 4500g, and put them into the drum mixer. In order to make the physical mixing more uniform, put 450g steel paper clips into the mixer, mix for 2 hours, and pass through the 60# screen to get Molding material;

[0043]2.2 Put the above-mentioned mixture and the aluminum matrix of the corresponding size into the mold at the same time, heat and press on the hot press, the hot pressing temperature is 195°C, the pressure starts from 2Mpa, flatten the mold for 15 minutes, and keep it after flattening The pressure and temperature of flattening are 180 minutes, and the mold is unloaded to obtain the ...

Embodiment 2

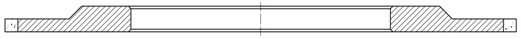

[0046] Make 3A1-400×20×203×10×10 cylindrical grinding semi-finishing grinding wheels with a particle size of 180#, see figure 2 .

[0047] 1. Formula: According to the following table:

[0048] 3A1-400×20×203×10×10 Granularity 180# Cylindrical grinding semi-fine grinding wheel formula

[0049]

[0050] Second, the production process

[0051] 2.1 Weigh the materials with the above formula ratio, the total weight is 3500g, and put them into the drum mixer. In order to make the physical mixing more uniform, put 350g steel paper clips into the mixer, mix for 1.5 hours, and pass through the 100# screen to get Molding material;

[0052] 2.2 Put the above-mentioned mixture and the aluminum matrix of the corresponding size into the mold at the same time, heat and press on the hot press, the hot pressing temperature is 195°C, the pressure starts from 2Mpa, flatten the mold for 15 minutes, and keep it after flattening The pressure and temperature of flattening are 170 minutes, a...

Embodiment 3

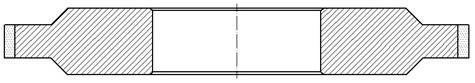

[0055] To make 14A1-350×40×127×30×5 cylindrical grinding wheels with a particle size of 800#, see image 3 .

[0056] 1. Formula: According to the following table:

[0057] 14A1-350×40×127×30×5 Granularity 800# Cylindrical Grinding Grinding Wheel Formula

[0058]

[0059] Second, the production process

[0060] 2.1 Weigh the materials with the above formula ratio, with a total weight of 4000g, and put them into the drum mixer. In order to make the physical mixing more uniform, put 400g steel paper clips into the mixer, mix for 2.5 hours, and pass through the 140# screen to get Molding material;

[0061] 2.2 Put the above-mentioned mixture and the aluminum matrix of the corresponding size into the mold at the same time, heat and press on the hot press, the hot pressing temperature is 185°C, and the pressure starts from 2Mpa, flatten the mold for 15 minutes, and keep it after flattening The pressure and temperature of flattening are 240 minutes, and the mold is unloaded t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com