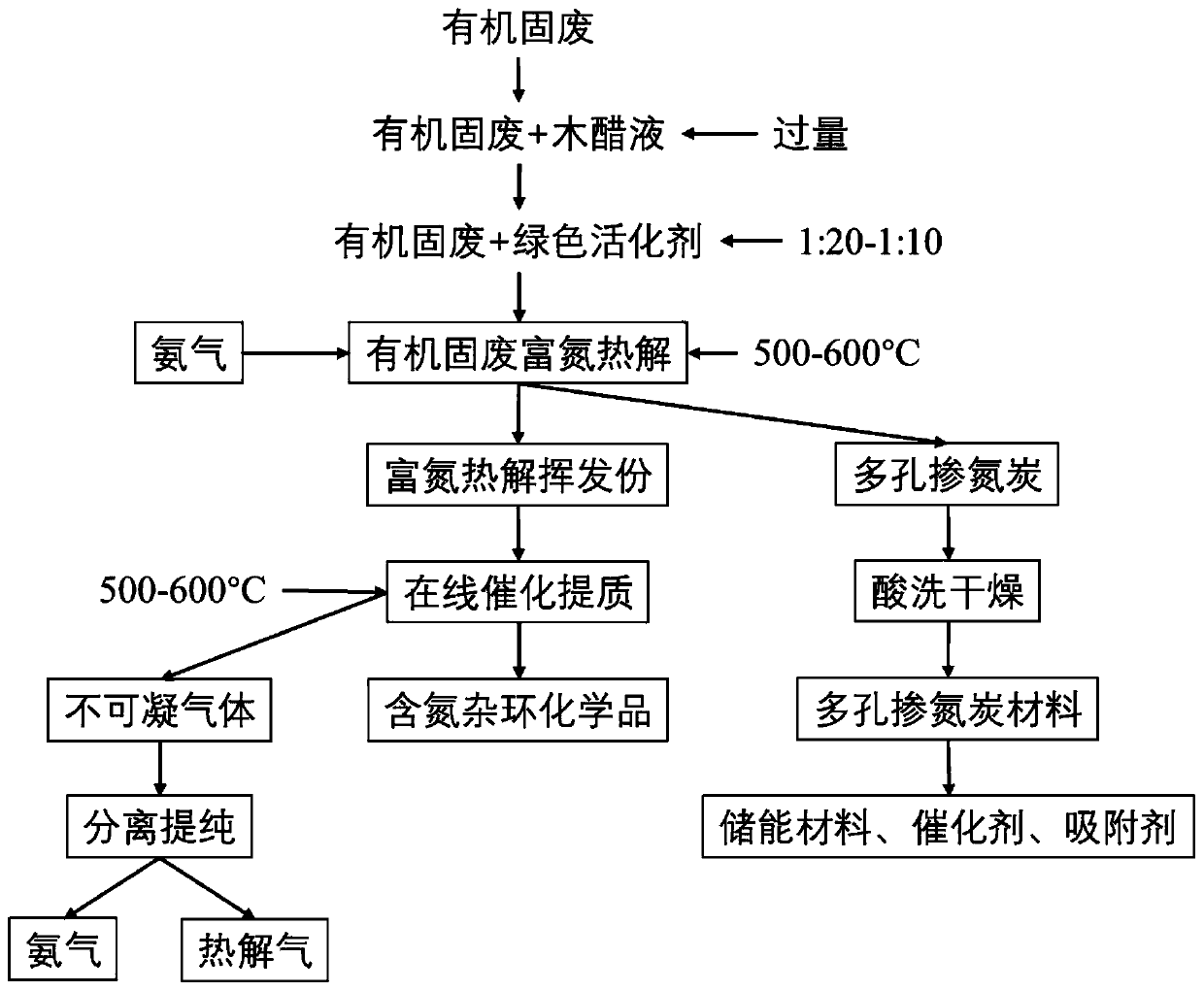

Method for co-production of nitrogen-containing heterocyclic chemicals and nitrogen-doped carbon by nitrogen-rich catalytic pyrolysis

A technology of catalytic pyrolysis and nitrogen heterocycle, applied in organic chemistry, carbon preparation/purification, etc., can solve problems such as corrosion, low selectivity of liquid products, difficulty in balancing liquid and solid products, etc., achieve low cost, increase ammonia Utilization rate, low corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The embodiment of the present invention describes a method for nitrogen-rich catalytic pyrolysis to co-produce nitrogen-containing heterocyclic chemicals and nitrogen-doped carbon. The method specifically includes the following steps:

[0047] S1: After crushing the sawdust, soak it with excess wood vinegar for 24 hours to remove impurities such as alkali metals in the sawdust, filter, rinse and dry to obtain pickled raw materials, the drying temperature is 105°C, and the drying time is 24 hours ,

[0048] S2: Fully mechanically mix the acid-washed sawdust with the green activator, the green activator KHCO 3 The mass ratio with sawdust is 1:20 to obtain a mixed sample,

[0049] S3: Put 2g of the mixed sample into the first stage of a two-stage fixed-bed reactor (diameter 45mm, length 60cm), and feed pure ammonia gas for nitrogen-enriched pyrolysis reaction, ammonia gas and green activator KHCO 3 The synergistic effect promotes the pore-forming reaction of sawdust mixe...

Embodiment 2

[0056] S1: After crushing the sawdust, soak it with excess wood vinegar for 24 hours to remove impurities such as alkali metals in the sawdust, filter, rinse and dry to obtain pickled raw materials, the drying temperature is 105°C, and the drying time is 24 hours ,

[0057] S2: Fully mechanically mix the acid-washed sawdust with the green activator, the green activator KHCO 3 The mass ratio with sawdust is 1:15 to obtain a mixed sample,

[0058] S3: Put 2g of the mixed sample into the first stage of a two-stage fixed-bed reactor (diameter 45mm, length 60cm), and feed pure ammonia gas for nitrogen-enriched pyrolysis reaction, ammonia gas and green activator KHCO 3 The synergistic effect promotes the pore-forming reaction of sawdust mixed with nitrogen. The reaction temperature is 550°C, the reaction time is 20min, and the ammonia flow rate is 200mL / min.

[0059] S4: Pass nitrogen-rich pyrolysis volatiles into the second stage of the two-stage fixed-bed reactor, and carry out ...

Embodiment 3

[0065] S1: After crushing the sawdust, soak it with excess wood vinegar for 24 hours to remove impurities such as alkali metals in the sawdust, filter, rinse and dry to obtain pickled raw materials, the drying temperature is 105°C, and the drying time is 24 hours ,

[0066] S2: Fully mechanically mix the acid-washed sawdust with the green activator, the green activator KHCO 3 The mass ratio with sawdust is 1:10 to obtain a mixed sample,

[0067] S3: Put 2g of the mixed sample into the first stage of a two-stage fixed-bed reactor (diameter 45mm, length 60cm), and feed pure ammonia gas for nitrogen-enriched pyrolysis reaction, ammonia gas and green activator KHCO 3 The synergistic effect promotes the pore-forming reaction of sawdust mixed with nitrogen. The reaction temperature is 600°C, the reaction time is 40min, and the ammonia flow rate is 500mL / min.

[0068]S4: Pass nitrogen-rich pyrolysis volatiles into the second stage of the two-stage fixed-bed reactor, and carry out o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com