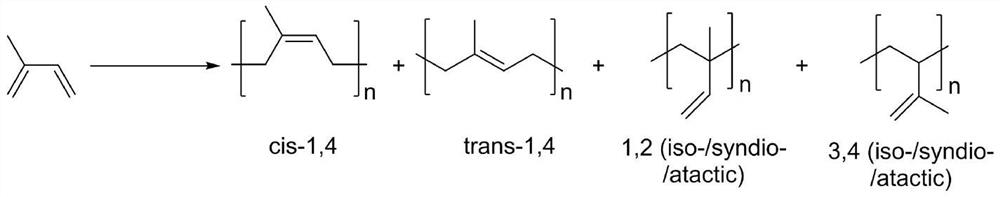

A kind of high-efficiency and controllable method for preparing polyisoprene

A technology for polyisoprene and isoprene, which is applied in the field of efficient and controllable preparation of polyisoprene, can solve the problems of low activity of iron-based catalysts, uncontrollable selectivity, easy deactivation of catalysts, etc. Good industrial application prospect, easy operation, high activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

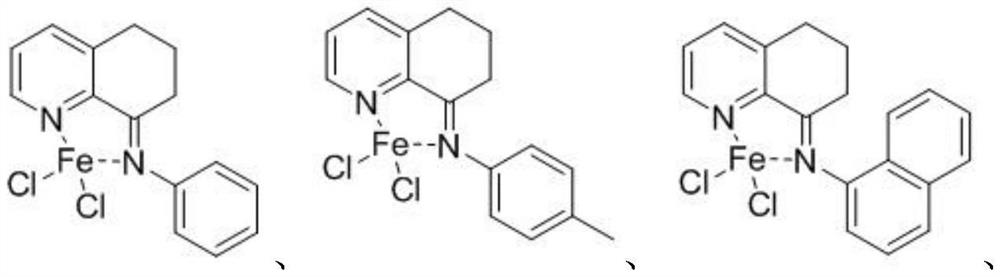

[0029] Embodiment 1: The structural formula of the rigid framework iron complex 1a of this embodiment is:

[0030]

[0031] Its specific synthesis method is as follows: add FeCl to a 100mL single-necked flask 2 (146.4mg, 1.2mmol, 1.0equiv), then dissolved in 2mL of glacial acetic acid, and then added 6,7-dihydro-5H-quinolin-8-one (170.0mg, 1.2mmol, 1.0equiv) and aniline (107.6 mg, 1.2 mmol, 1.0 equiv) solution in glacial acetic acid (8 mL), refluxed at 130 ° C for 12 hours, cooled to room temperature, added ether (50 mL), and a purple solid was precipitated; filtered, and washed with 30 mL of ether three times to obtain a purple Solid, rigid framework iron complex 1a.

[0032] Result: Yield 53.9%.

[0033] Infrared analysis: FT-IR (KBr, disk, cm -1 ): 3060, 2948, 1623, 1585 (ν, C=N), 1486, 1450, 1335, 1202, 1130, 790, 698.

[0034] Elemental Analysis: Anal.Calcd for C 30 H 28 Cl 4 Fe 2 N 4 : C, 51.62%; H, 4.04%; N, 8.03%. Found: C, 51.24%; H, 3.65%; N, 7.83%.

[0...

specific Embodiment approach 2

[0036] Embodiment 2: The structural formula of the rigid framework iron complex 2a of this embodiment is:

[0037]

[0038] Its specific synthesis method is as follows: add FeCl to a 100mL single-necked flask 2 (86.1 mg, 0.7 mmol, 1.0 equiv), then dissolved in 2 mL of glacial acetic acid; then added 6,7-dihydro-5H-quinolin-8-one (100.0 mg, 0.7 mmol, 1.0 equiv) and p-toluidine respectively (72.8 mg, 0.7 mmol, 1.0 equiv) in glacial acetic acid (8 mL), refluxed at 130°C for 12 hours, cooled to room temperature, and a large amount of ether (50 mL) was added to precipitate a dark brown solid; filter, and wash with 30 mL of ether for 3 Next, a dark brown solid, the rigid framework iron complex 2a, was obtained.

[0039] Result: Yield 60.6%.

[0040] Infrared analysis: FT-IR (KBr, disk, cm -1 ): 2943, 1578 (ν, C=N), 1505, 1455, 1357, 1337, 1219, 1110, 837, 791, 770.

[0041] Elemental Analysis: Anal.Calcd for [C 32 H 32 Cl 4 Fe 2 N 4 ][CH 3 COOH][H 2 O]: C, 50.78%; H, 4...

specific Embodiment approach 3

[0043] Embodiment 3: The structural formula of the rigid framework iron complex 3a of this embodiment is:

[0044]

[0045] Its specific synthesis method is as follows: add FeCl to a 100mL single-necked flask 2(99.0 mg, 0.8 mmol, 1.0 equiv), then dissolved in 2 mL of glacial acetic acid; 6,7-dihydro-5H-quinolin-8-one (115.0 mg, 0.8 mmol, 1.0 equiv) and 1-naphthalene were added respectively A solution of amine (111.9 mg, 0.8 mmol, 1.0 equiv) in glacial acetic acid (8 mL) was refluxed at 130 °C for 12 hours, cooled to room temperature, a large amount of ether (50 mL) was added, and a gray-brown solid was precipitated; filtered, and washed with 30 mL of ether 3 times to obtain a gray-brown solid, the rigid framework iron complex 3a.

[0046] Result: Yield 51.6%.

[0047] Infrared analysis: FT-IR (KBr, disk, cm -1 ): 3054, 2942, 1626, 1583 (ν, C=N), 1452, 1390, 1333, 1285, 1216, 1130, 781.

[0048] Elemental Analysis: Anal.Calcd for [C 38 H 32 Cl 4 Fe 2 N 4 ][3H 2 O]:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com