Preparation method of Sr-doped BaTiO3/ZnTe photocathode material

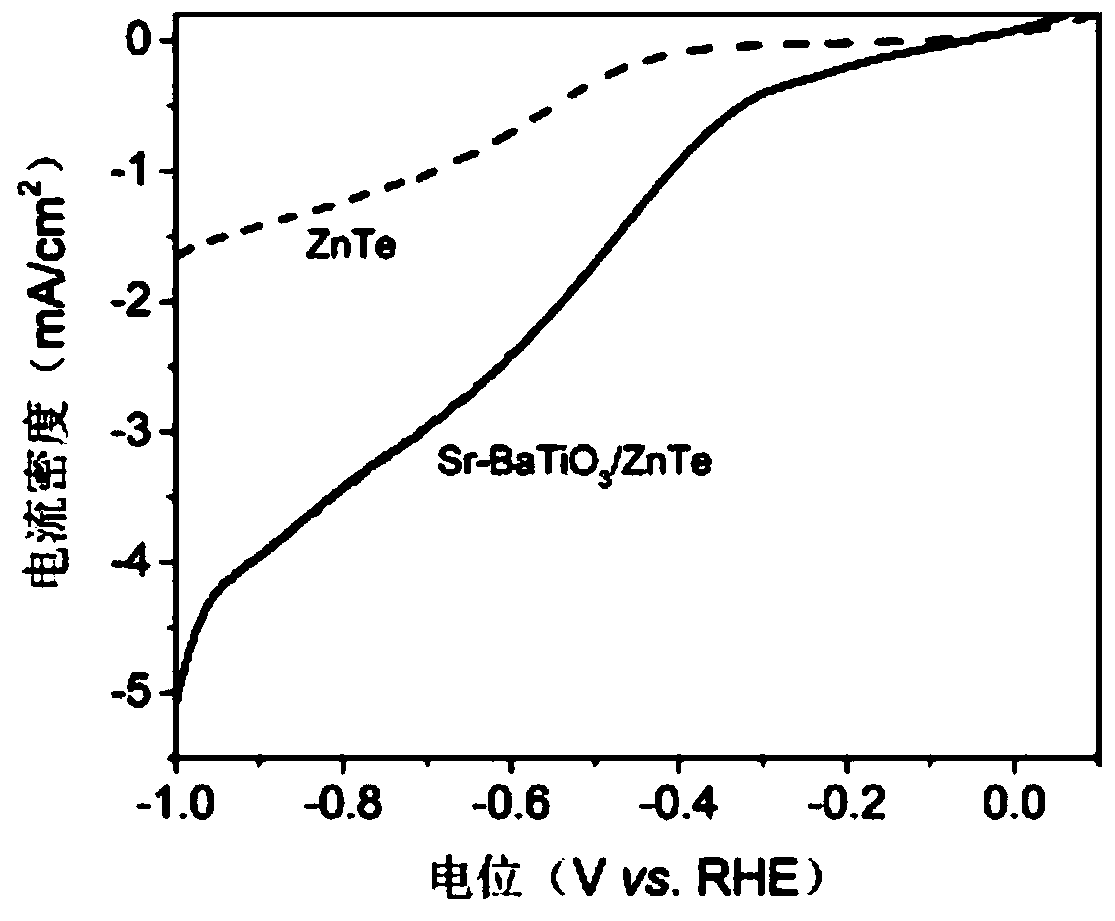

A photocathode and photoelectrode technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, electrodes, etc., can solve problems such as limiting the selection of semiconductor materials, and achieve strong spontaneous polarization ability and preparation The process is simple and the effect of reducing the composite speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

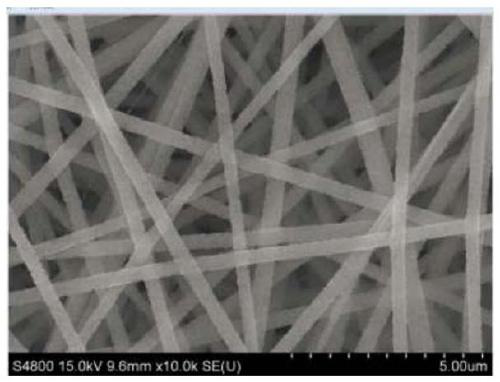

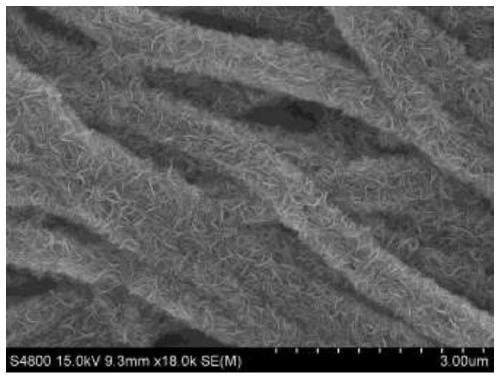

[0024] A Sr-doped BaTiO 3 The preparation method of / ZnTe photocathode material, concrete steps are as follows:

[0025] Weigh 0.13g of barium acetate, 0.05g of strontium acetate and 0.17g of tetrabutyl titanate, add 2ml of acetic acid, 6ml of ethanol and 6ml of water in sequence, and stir for a certain period of time to completely dissolve the solid powder; then, add 0.4g of polyvinylpyrrolate Alkanone, stirred for 24 hours to obtain a spinning solution; pipette 7ml of spinning solution into a 10ml syringe, and set the electrospinning process parameters: syringe advancing speed 3mm / h, spinning voltage 18kV, receiving distance 8cm, drum speed 200r / min , the solidified composite fiber was received on the FTO glass fixed on the drum, dried in an oven at 150 °C overnight, and then placed in a muffle furnace at 600 °C for calcination for 2 hours, and Sr-doped BaTiO could be obtained after thermal decomposition 3 Thin film electrode; prepare 30ml of mixed water with a concentration...

Embodiment 2

[0028]Weigh 0.13g of barium acetate, 0.02g of strontium acetate and 0.17g of tetrabutyl titanate, add 2ml of acetic acid, 6ml of ethanol and 6ml of water in sequence, and stir for a certain period of time to completely dissolve the solid powder; then, add 0.35g of polyvinylpyrrolate Alkanone, stirred for 24 hours to obtain a spinning solution; pipette 7ml spinning solution into a 10ml syringe, set the electrospinning process parameters: injector advance speed 3mm / h, spinning voltage 12kV, receiving distance 10cm, drum speed 300r / min , the solidified composite fiber was received on the FTO glass fixed on the drum, dried in an oven at 150°C overnight, and then placed in a muffle furnace at 650°C for calcination for 2 hours, and Sr-doped BaTiO could be obtained after thermal decomposition 3 Thin film electrode; prepare 30ml of mixed water with a concentration of 4mmol / L zinc nitrate, 4mmol / L sodium tellurate and 0.5mmol / L sodium borohydride to dissolve, stir evenly, and transfer t...

Embodiment 3

[0031] Weigh 0.13g of barium acetate, 0.08g of strontium acetate and 0.17g of tetrabutyl titanate, add 2ml of acetic acid, 8ml of ethanol and 8ml of water in sequence, and stir for a certain period of time to completely dissolve the solid powder; then, add 0.5g of polyvinyl pyrrole Alkanone, stirred for 24 hours to obtain a spinning solution; pipette 7ml of spinning solution into a 10ml syringe, and set the electrospinning process parameters: syringe advancing speed 3mm / h, spinning voltage 20kV, receiving distance 8cm, drum speed 200r / min , the solidified composite fiber was received on the FTO glass fixed on the drum, dried in an oven at 150°C overnight, and then placed in a muffle furnace at 550°C for calcination for 2 hours, and Sr-doped BaTiO could be obtained after thermal decomposition 3 Thin film electrode; prepare 30ml of mixed water with a concentration of 3.5mmol / L zinc nitrate, 3.5mmol / L sodium tellurate and 0.3mmol / L sodium borohydride to dissolve, stir evenly, tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com