Preparation method and product of a single-layer atomic channel fin field effect transistor

A fin-type field effect, transistor technology, applied in the field of applied research, to achieve the effects of good ohmic contact, strong gate control ability, and rich selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

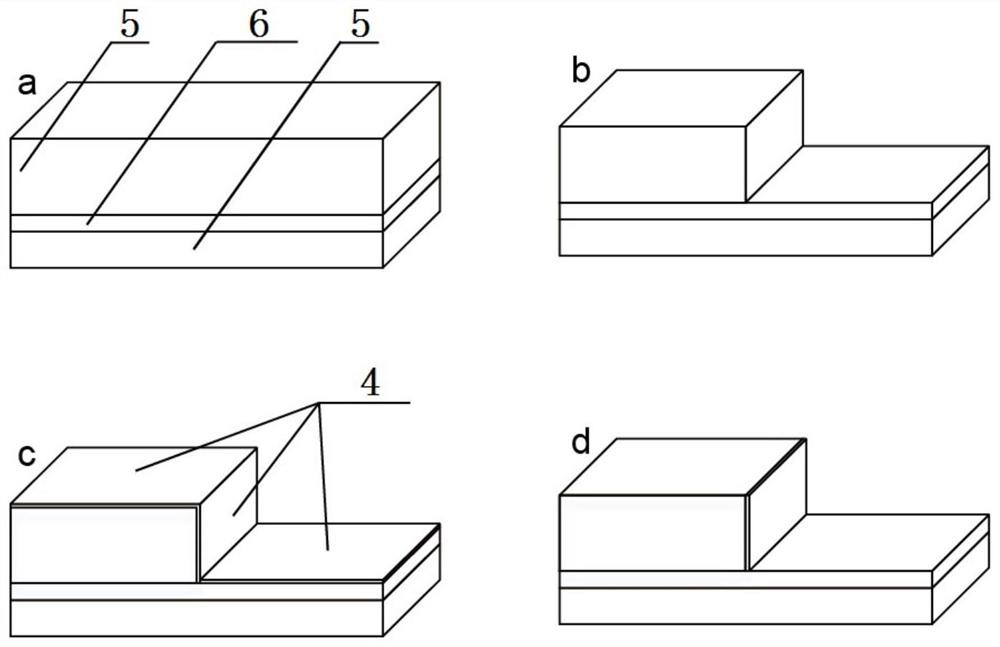

[0062] (1) SOI substrate of 300 nanometer silicon on the top layer (structural schematic diagram as image 3 Shown in a) The surface was spin-coated with LOR-7A (3K rpm, heated at 190°C, 5 minutes) and PMMA950K A7 (5K rpm, heated at 190°C, 5 minutes), and then exposed by electron beam exposure technology, and developed with Solution 1 (IPA / DI Water=1 / 3) was developed for 1 minute, developer 2 (CD-26) was developed for 35 seconds, and dried with nitrogen. Then use electron beam evaporation to deposit 200 nm thick metal nickel as a protective layer, and use inductively coupled plasma etching to remove the SOI top layer silicon material without metal protection, and finally dissolve the metal nickel with hydrochloric acid to obtain a vertical step pattern. The schematic diagram of the structure is as follows image 3 As shown in b, the actual enlarged picture is shown in Figure 4 shown;

[0063] (2) Use the atomic layer deposition method to deposit a uniform and dense hafnium ...

Embodiment 2

[0072] The difference from Example 1 is: the SOI substrate described in step (1) can be replaced with other substrates, such as a substrate with a similar SOI type three-layer structure, or a double-layer structure substrate, wherein the top layer can be Semiconductor, metal or insulator, the underlying material is an insulator.

[0073] Finfield-effect transistors with single-atom-layer-thick channel materials can be obtained.

Embodiment 3

[0075] The difference from Example 1 lies in that the thickness of the SOI top layer silicon in step (1) is different.

[0076] FinFETs with single-atom-layer-thick channel materials are available at different heights (up to microns).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com