Single-electron transmission avalanche photodiode structure and manufacturing method

An avalanche photoelectric and diode technology, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as increased leakage current, damage, and inability to meet device bandwidth and overload optical power at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

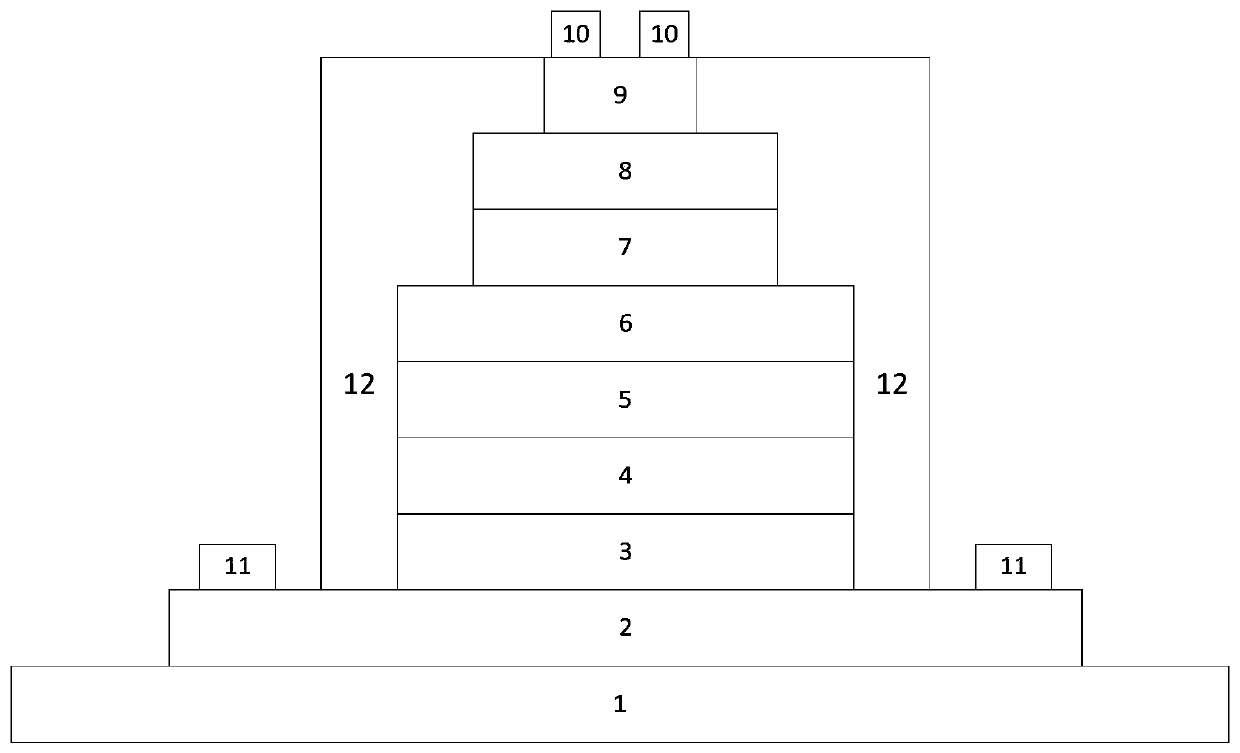

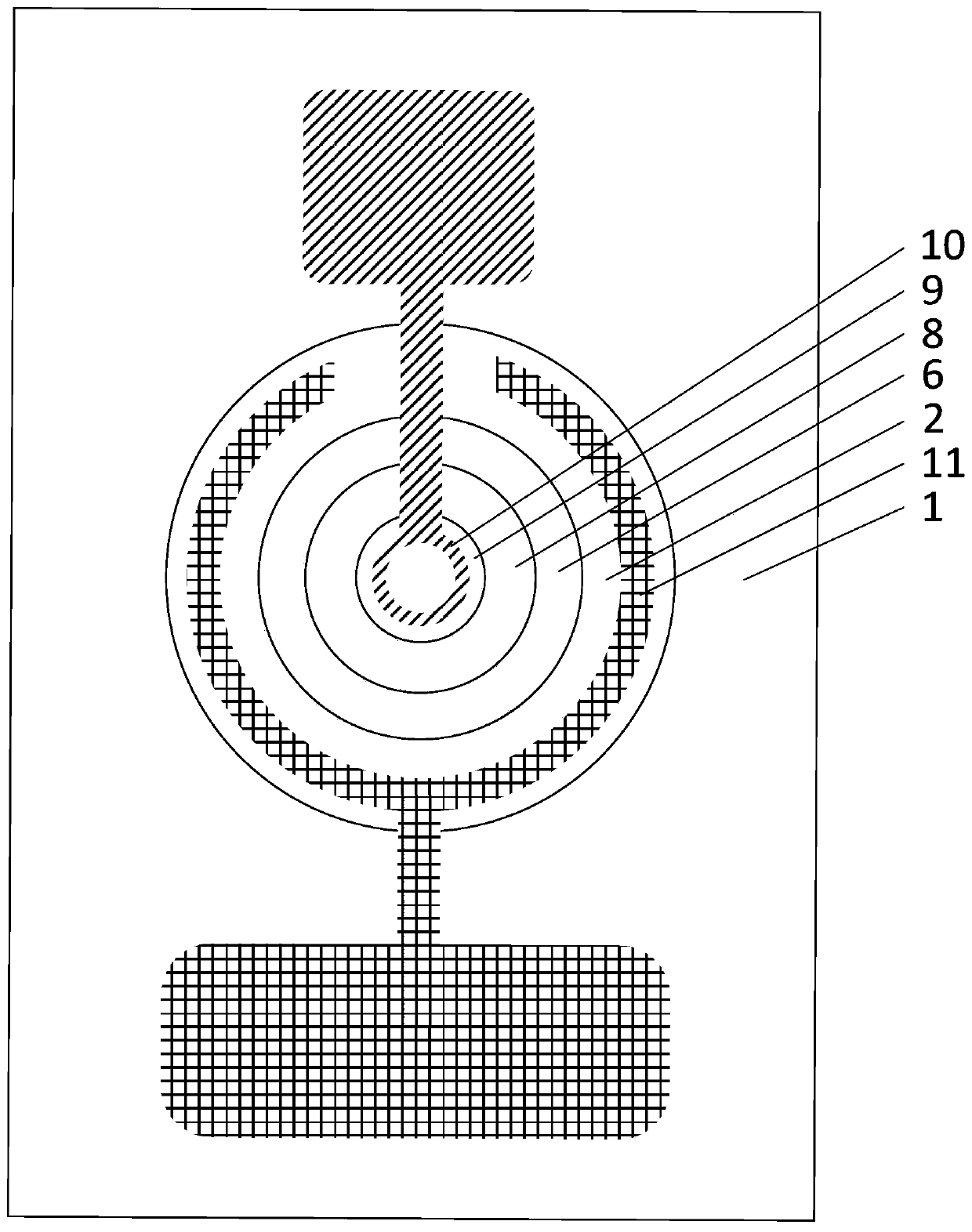

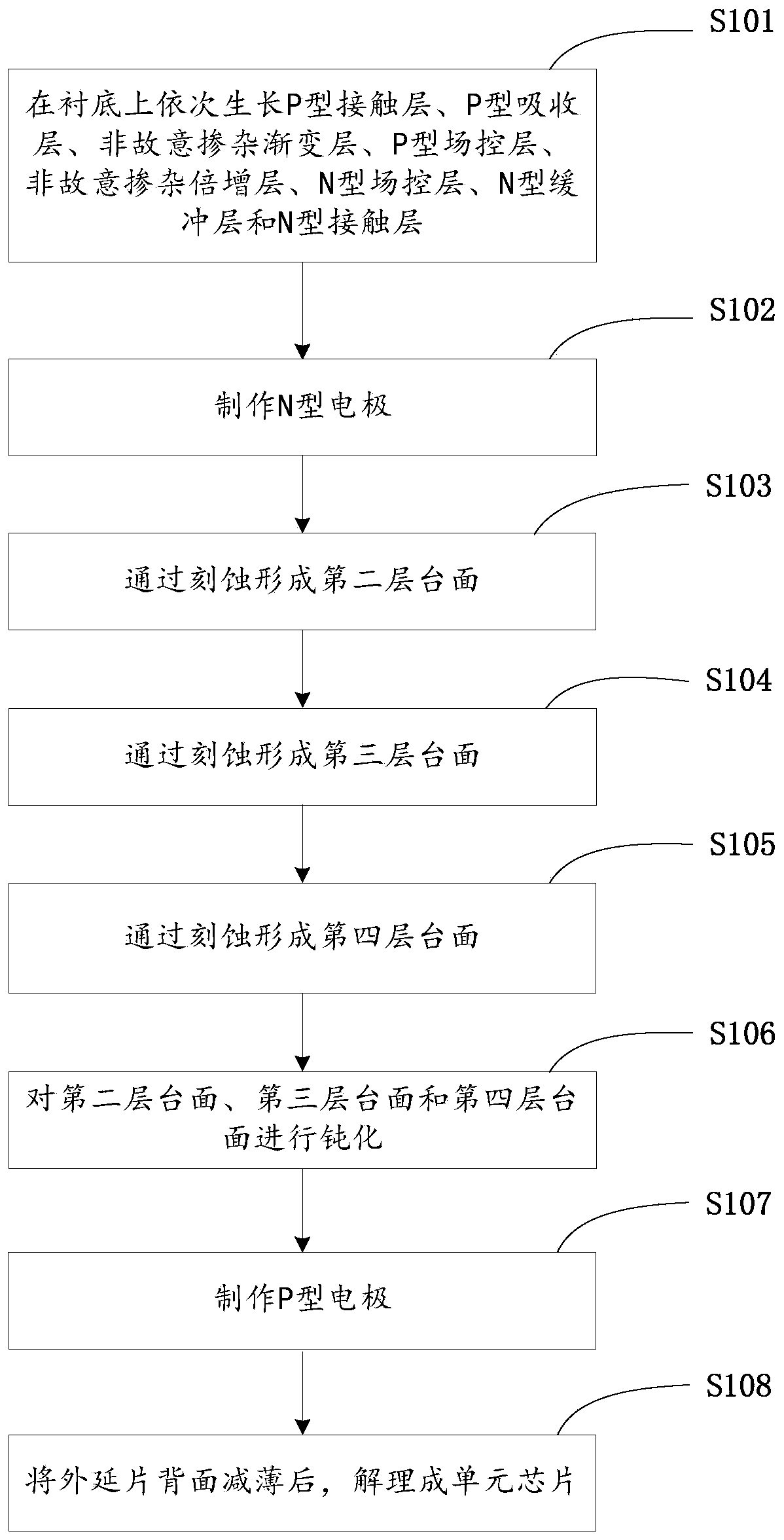

[0045] Such as figure 1 and figure 2 As shown, one embodiment of the single electron transport avalanche photodiode structure of the present invention comprises an InP semi-insulating substrate 1, on which a P-type InAlGaAs contact layer 2, a P-type InAlGaAs contact layer 2, and a P-type In 0.53 Ga 0.47 As absorption layer 3, unintentionally doped InGaAlAs graded layer 4, P-type In 0.52 al 0.48 As field control layer 5, unintentionally doped In 0.52 al 0.48 As multiplication layer 6, N-type In 0.52 al 0.48 As field control layer 7, N-type In 0.52 al 0.48 As buffer layer 8 and N-type In 0.53 Ga 0.47 As contact layer 9; the N-type In 0.53 Ga 0.47 The As contact layer 9 is connected to an N-type electrode 10 , and the P-type InAlGaAs contact layer 2 is connected to a P-type electrode 11 .

[0046] The photodiode structure is a concentric circular structure with four layers of mesas, and the first layer of mesas is N-type In 0.53 Ga 0.47 The upper surface of the As...

Embodiment 2

[0070] Such as Figure 4 and Figure 5 As shown, another embodiment of the single electron transport avalanche photodiode structure of the present invention includes an InP semi-insulating substrate 1', and N-type In is grown sequentially on the InP semi-insulating substrate 1'. 0.52 al 0.48 As contact layer 9', unintentionally doped In 0.52 al 0.48 As multiplication layer 6', P-type In 0.52 al 0.48 As field control layer 5', unintentionally doped InGaAlAs graded layer 4', P-type In 0.53 Ga 0.47 As absorption layer 3' and P-type In 0.53 Ga 0.47 As contact layer 20, the P-type In 0.53 Ga 0.47 The As contact layer 20 is connected with a P-type electrode 11', and the N-type In 0.52 al 0.48 The As contact layer 9' is connected to an N-type electrode 10'.

[0071] The photodiode structure is a concentric circular structure with three layers of mesas, and the first layer of mesas is P-type In 0.53 Ga 0.47 The upper surface of the As contact layer 20, the second mesa i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com