Additive-free normal-temperature yoghourt and preparation method thereof

A technology without additives and at room temperature, applied to milk preparations, bacteria used in food preparation, dairy products, etc., can solve the problems of containing and other problems, and achieve the effect of rich nutrition, strong fermented flavor, and smooth taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

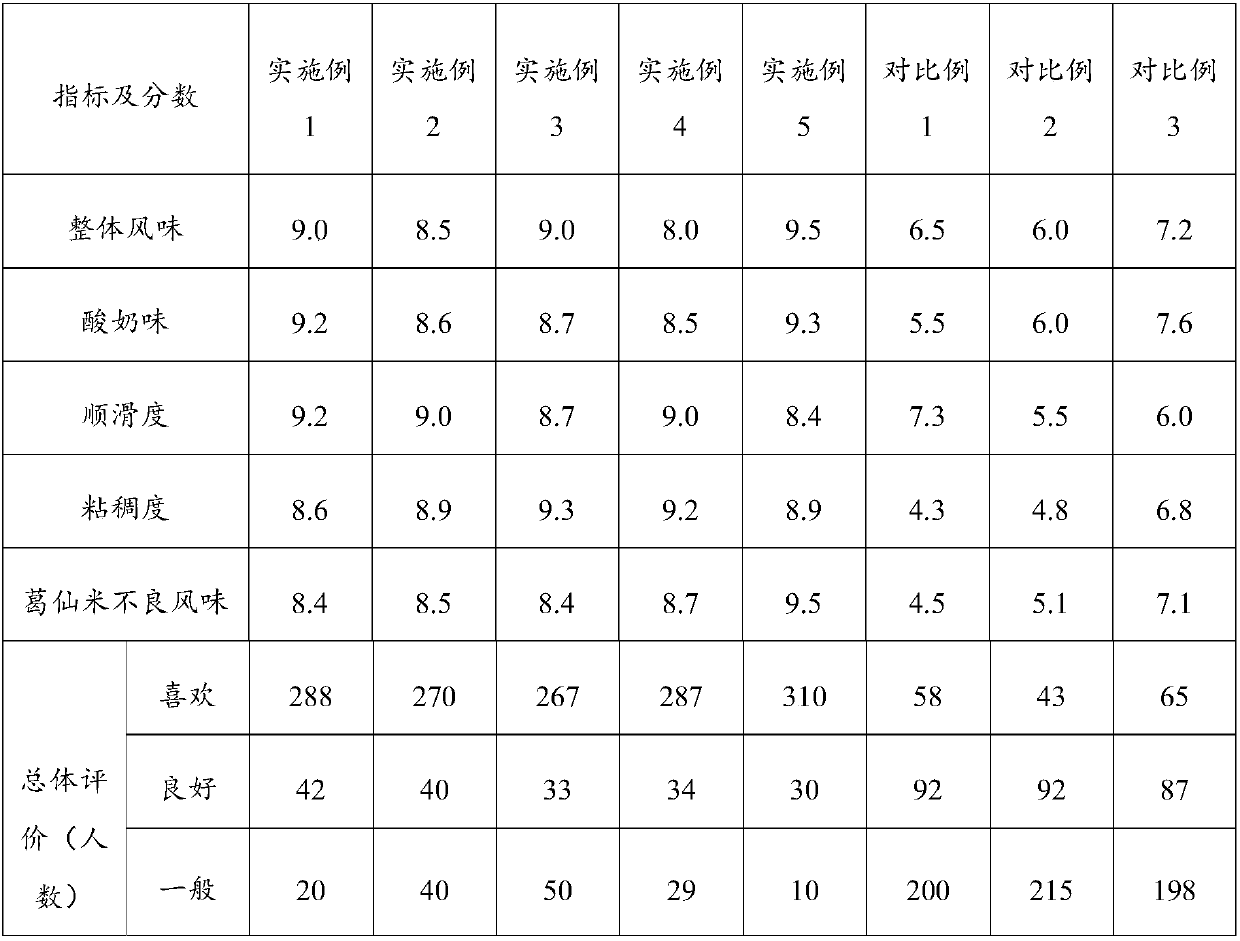

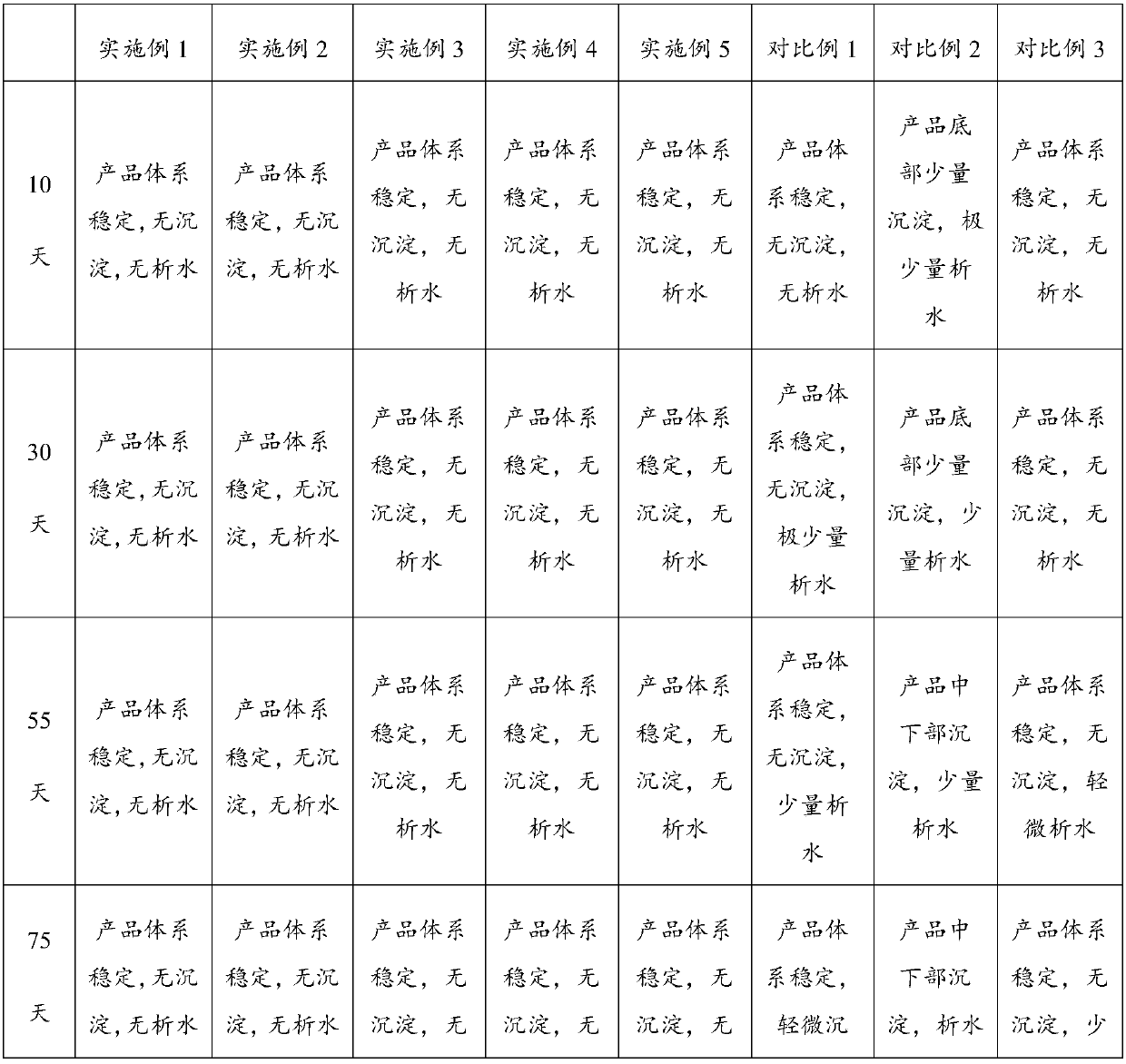

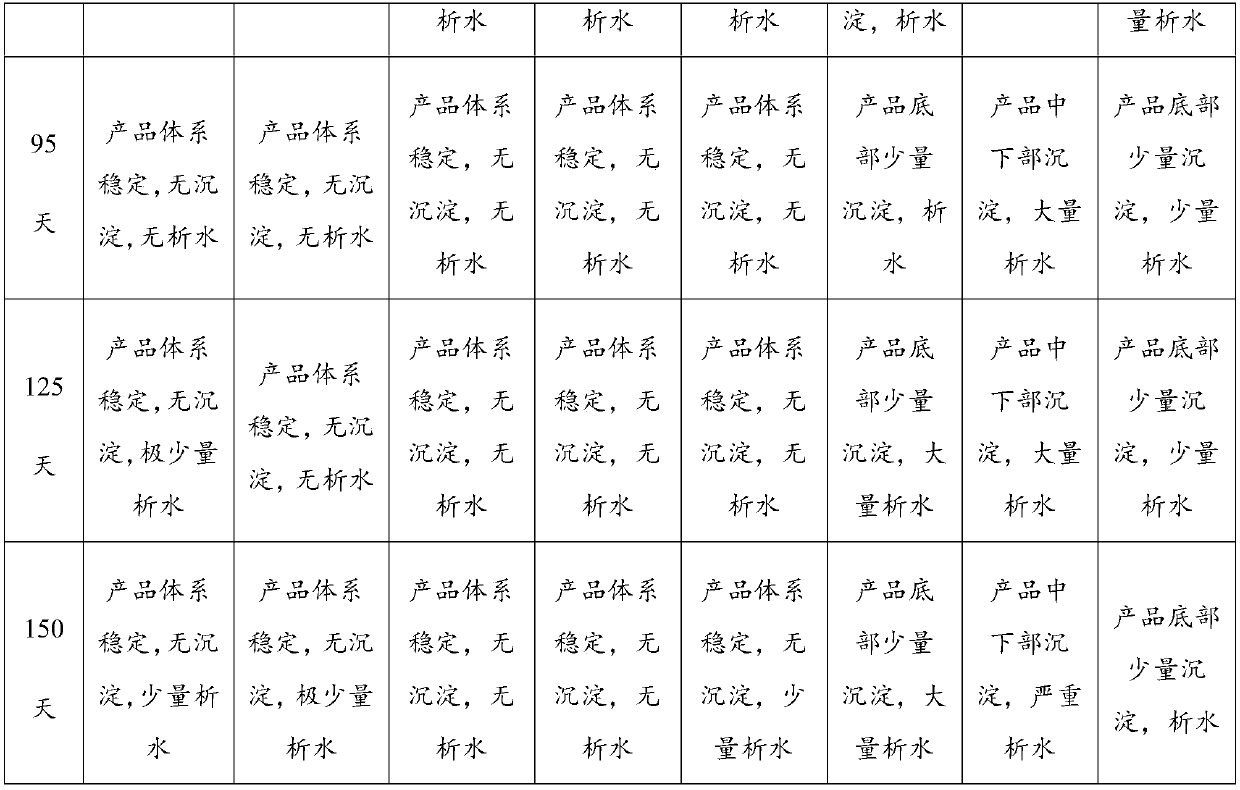

Examples

Embodiment 1

[0067] This example provides a normal temperature yoghurt without additives, the specific composition and preparation method are as follows:

[0068] Fermented milk raw materials (based on 1000 kg): milk: 910 kg, white sugar: 90 kg, starter: 100U.

[0069] Raw material of fermented kudzu rice (in 1000 kg): kudzu rice flour: 50 kg, water: 950 kg, starter: 200U.

[0070] Preparation of fermented milk:

[0071] (1) Heating high-quality raw milk with a protein content of more than 3.3% to 55°C, adding white sugar, and dissolving it through a high-speed shearing machine, the speed of which is 500 rpm, and dissolving for 20 minutes;

[0072] (2) Raise the temperature of the feed liquid to 65°C, and homogenize it through a homogenizer with a homogenization pressure of 18Mpa;

[0073] (3) The homogenized feed liquid is sterilized at 105°C for 3 minutes;

[0074] (4) Reduce the temperature of the sterilized feed liquid to 37° C., add Streptococcus thermophilus starter for fermentati...

Embodiment 2

[0085] This example provides a normal temperature yoghurt without additives, the specific composition and preparation method are as follows:

[0086] Fermented milk raw materials (based on 1000 kg): milk: 920 kg, white sugar: 80 kg, starter: 90U.

[0087] Raw material of fermented kudzu rice (in 1000 kg): kudzu rice flour: 100 kg, water: 900 kg, starter: 160U.

[0088] Preparation of fermented milk:

[0089] (1) Heat high-quality skimmed milk with a protein content of more than 3.3% to 45°C, add white sugar, and dissolve it through a high-speed shearing machine. The speed of the high-speed shearing machine is 1000 rpm, and dissolve for 10 minutes;

[0090] (2) Raise the temperature of the feed liquid to 55°C, and homogenize it through a homogenizer with a homogenization pressure of 22Mpa;

[0091] (3) The homogenized feed liquid is sterilized at 95°C for 8 minutes;

[0092] (4) Reduce the temperature of the sterilized feed liquid to 43° C., add Lactobacillus helveticus star...

Embodiment 3

[0103] This example provides a normal temperature yoghurt without additives, the specific composition and preparation method are as follows:

[0104] Fermented milk raw materials (based on 1000 kg): milk: 940 kg, erythrose: 60 kg, starter: 80U.

[0105] Raw material of fermented kudzu rice (in 1000 kg): kudzu rice flour: 150 kg, water: 850 kg, starter: 120U.

[0106] Preparation of fermented milk:

[0107] (1) Heating high-quality fresh milk with a protein content of more than 3.3% to 50°C, adding erythrose, and dissolving it through a high-speed shearing machine at a speed of 800 rpm for 15 minutes;

[0108] (2) Raise the temperature of the feed liquid to 60°C, and homogenize it through a homogenizer with a homogenization pressure of 20Mpa;

[0109] (3) The homogenized feed liquid is sterilized at 100°C for 5 minutes;

[0110] (4) Reduce the temperature of the sterilized feed liquid to 40° C., add Lactobacillus plantarum starter to ferment, and perform demulsification when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com