Controlled-release antibiotic expanded acrylic bone cement and preparation method thereof

A technology of antibiotics and bone cement, applied in the field of medical biomaterials, can solve the problems of low antibiotic release rate, achieve high expansion ratio and antibiotic release rate, long antibiotic release cycle, and reduce pain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

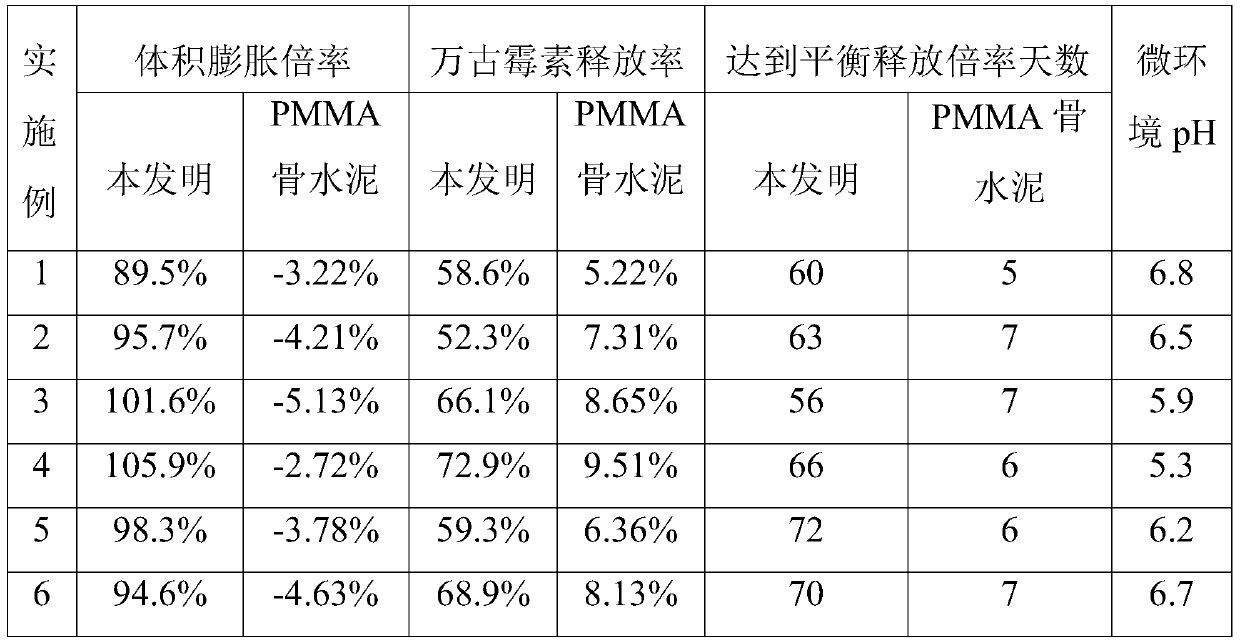

Examples

preparation example Construction

[0042] A kind of preparation method of controllable-release antibiotic expansion acrylic acid bone cement of the present invention comprises the following steps:

[0043] Step 1, prepare carboxylated graphene

[0044] Step 1.1, weigh graphene oxide, sodium hydroxide and monochloroacetic acid according to the mass ratio of 0.05~0.2:3~6:2~5, and mix graphene oxide with water to make the concentration 0.25mg / ml~2mg / ml ml of graphene oxide aqueous solution;

[0045] Step 1.2, ultrasonically disperse the graphene oxide aqueous solution to obtain a GO suspension, then add the weighed sodium hydroxide and monochloroacetic acid into the GO suspension and mix evenly, filter the mixed solution to obtain a solid product, and dry the solid product Finally, carboxylated graphene is obtained.

[0046] Step 2, preparation of polymethyl methacrylate-itaconic acid-carboxylated graphene-loaded antibiotic microspheres

[0047] Step 2.1, according to the mass ratio of 10:26:0.09~1.08:1.8~2.88:...

Embodiment 1

[0058] The preparation of a controlled-release antibiotic expanded acrylic bone cement comprises the following steps:

[0059] Step 1, prepare carboxylated graphene

[0060] Step 1.1, weigh 50mg graphene oxide (GO), 3g sodium hydroxide (NaOH) and 2g monochloroacetic acid (C 2 h 3 ClO 2 ), disperse 50mg graphene oxide (GO) in 100ml distilled water, make the graphene oxide aqueous solution that concentration is 0.5mg / ml;

[0061] Step 1.2, ultrasonically disperse the graphene oxide aqueous solution at room temperature for 1 hour to obtain a GO suspension; add the weighed sodium hydroxide and monochloroacetic acid into the GO suspension and shake for 3 hours, and wait until they are mixed evenly and after the reaction is complete, Filter the mixed solution to obtain a solid product, and dry the solid product at 70° C. for 48 hours to obtain carboxylated graphene (CG);

[0062] Step 2: Preparation of polymethyl methacrylate-itaconic acid-carboxylated graphene-loaded antibiotic...

Embodiment 2

[0075] The preparation of a controlled-release antibiotic expanded acrylic bone cement comprises the following steps:

[0076] Step 1, prepare carboxylated graphene

[0077] Step 1.1, weigh 200mg graphene oxide (GO), 6g sodium hydroxide (NaOH) and 5g monochloroacetic acid (C 2 h 3 ClO 2 ), disperse 200mg graphene oxide (GO) in 200ml distilled water, make the graphene oxide aqueous solution that concentration is 1mg / ml;

[0078] Step 1.2: Ultrasonic disperse the graphene oxide aqueous solution at room temperature to obtain a GO suspension; add the weighed sodium hydroxide and monochloroacetic acid into the GO suspension and shake for 5 hours, wait until they are evenly mixed, and after the reaction is complete, filter A solid product was obtained from the mixed solution, and the solid product was dried at 90° C. for 24 hours to obtain carboxylated graphene (CG);

[0079] Step 2: Preparation of polymethyl methacrylate-itaconic acid-carboxylated graphene-loaded antibiotic mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com