Foamed gypsum block and preparation method thereof

A technology of foamed gypsum and blocks, which is applied in the field of building materials, can solve the problems of high production cost, and achieve the effects of low production energy consumption, reduced consumption, and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

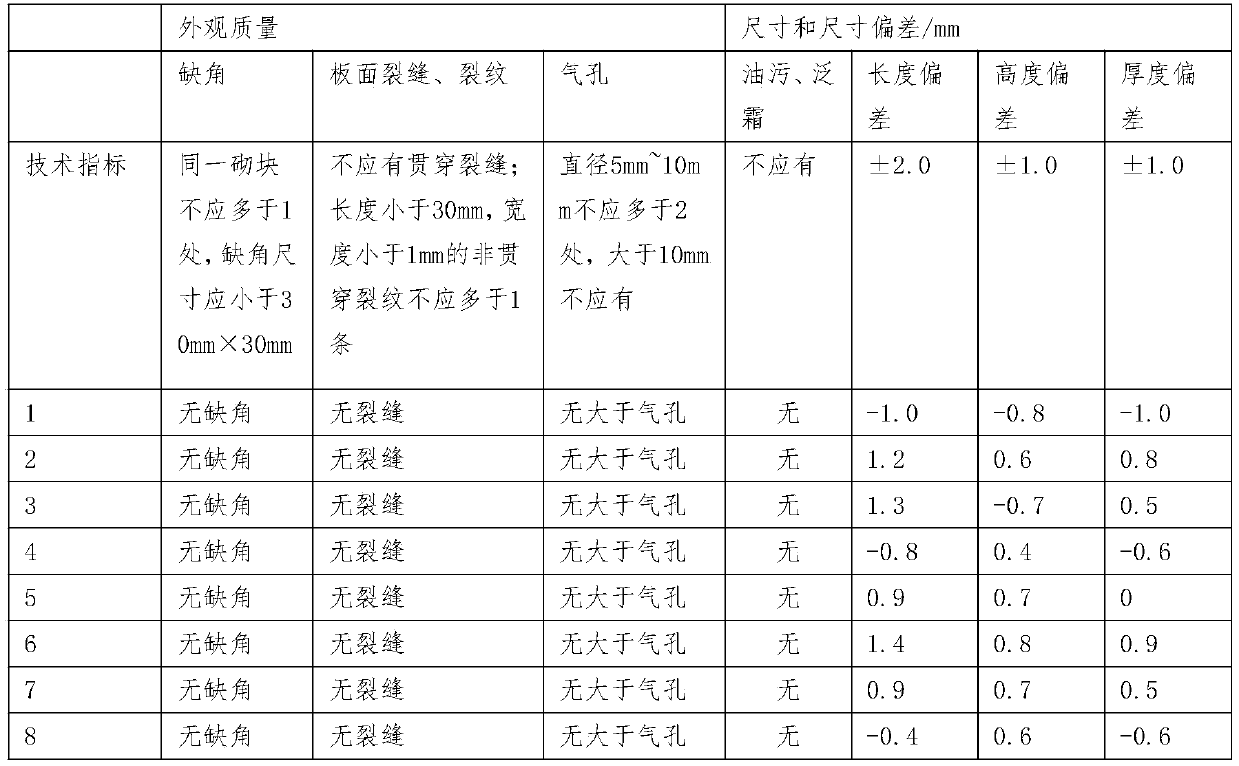

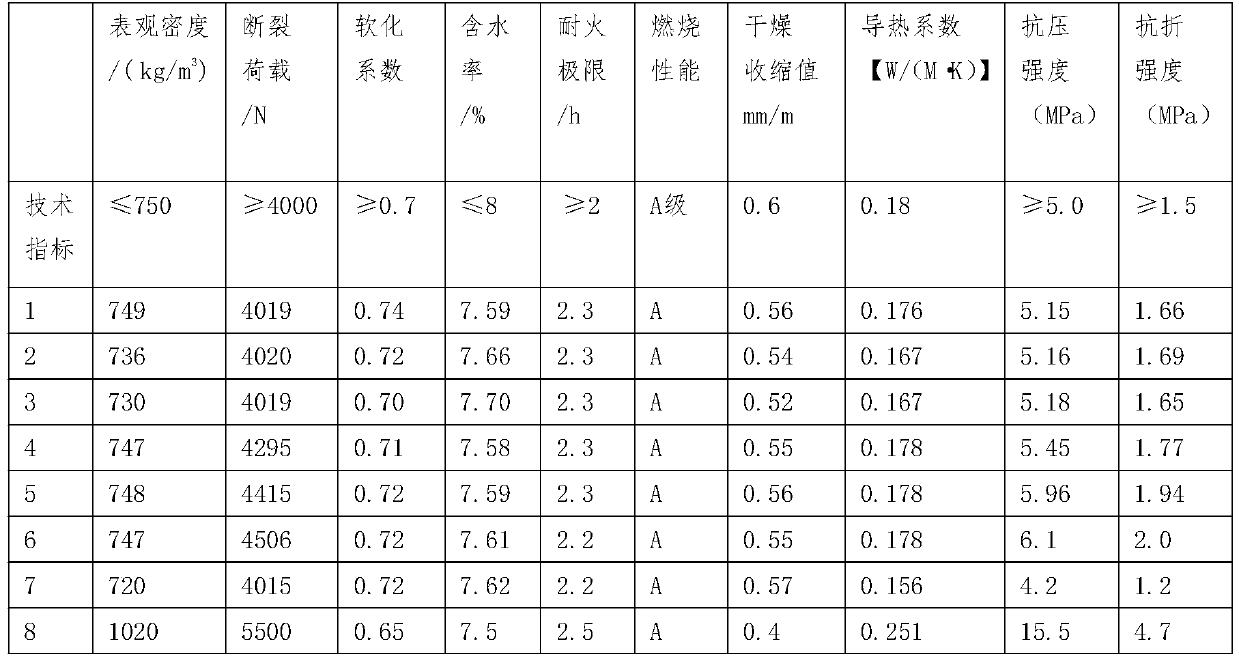

Examples

Embodiment 1

[0043] A kind of preparation method of foamed gypsum block, comprises the following steps:

[0044] (1) Mix the mixed-phase gypsum powder with cement and admixture evenly to obtain the mixed gypsum powder;

[0045] (2) Alkylsulfonic acid surfactants and cellulose ether stabilizers are mixed into a composite foaming agent according to a mass ratio of 5:0.2;

[0046] (3) Add the mixed gypsum powder so that the consistency of the gypsum slurry is 40mm, and then stir and mix evenly to obtain a gypsum slurry; mix the foaming agent and water according to the ratio of 1:20 and add it to the foaming machine for stirring form foam;

[0047] (4) mixing and stirring the gypsum slurry and the foam evenly to obtain a foaming slurry;

[0048] (5) The foamed slurry is poured into the mold, and the pouring body is naturally cured in the mold until the compressive strength is not less than 2.0MPa, and the mold can be demoulded;

[0049] (6) Take out the pouring body from the mold and cut it...

Embodiment 2

[0055] A kind of preparation method of foamed gypsum block, comprises the following steps:

[0056] (1) Mix the mixed-phase gypsum powder with cement and admixture evenly to obtain the mixed gypsum powder;

[0057] (2) Mix alkylsulfonic acid surfactants and cellulose ether stabilizers in a mass ratio of 5:0.25 to form a foaming agent;

[0058] (3) Add the mixed gypsum powder so that the consistency of the gypsum slurry is 50mm, and then stir and mix evenly to obtain a gypsum slurry; mix the foaming agent and water according to the ratio of 1:15 and add it to the foaming machine for stirring form foam;

[0059] (4) mixing and stirring the gypsum slurry and the foam evenly to obtain a foaming slurry;

[0060] (5) The foamed slurry is poured into the mold, and the pouring body is naturally cured in the mold until the compressive strength is not less than 2.0MPa, and the mold can be demoulded;

[0061] (6) Take out the pouring body from the mold and cut it into blocks of requir...

Embodiment 3

[0067] A kind of preparation method of foamed gypsum block, comprises the following steps:

[0068] (1) Mix the mixed-phase gypsum powder with cement and admixture evenly to obtain the mixed gypsum powder;

[0069] (2) Alkylsulfonic acid surfactants and cellulose ether stabilizers are mixed into a foaming agent in a mass ratio of 5:0.2 as determined by experiments;

[0070] (3) Add the mixed gypsum powder so that the consistency of the gypsum slurry is 50 mm of water and mix it evenly to make a gypsum slurry; mix the foaming agent and water in a ratio of 1:10 and add it to the foaming machine for stirring form foam;

[0071] (4) mixing and stirring the gypsum slurry and the foam evenly to obtain a foaming slurry;

[0072] (5) The foamed slurry is poured into the mold, and the pouring body is naturally cured in the mold until the compressive strength is not less than 2.0MPa, and the mold can be demoulded;

[0073] (6) Take out the pouring body from the mold and cut it into b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com